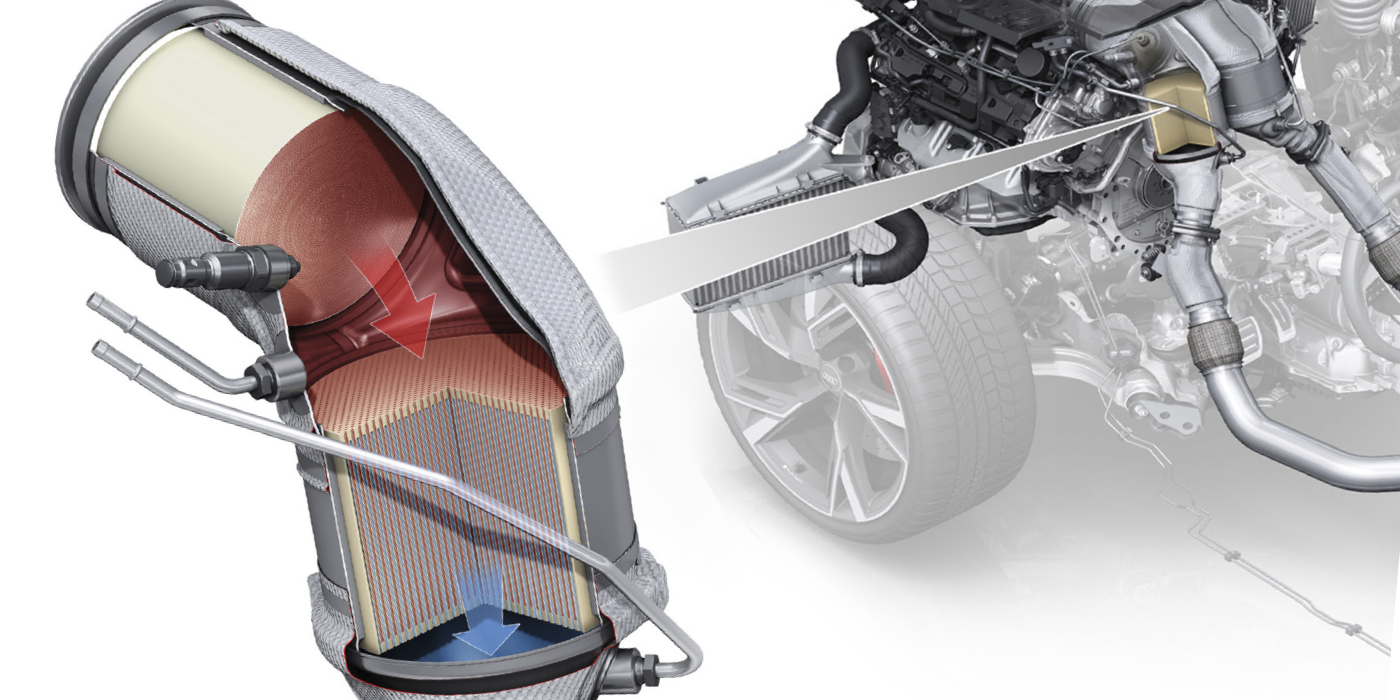

In 2008, when the EPA mandated diesel particulate filters for medium and heavy-duty trucks and annual smog testing to make sure the diesel particulate filter (DPF) parts were present, you would’ve thought it was the end of the road for diesel engines.

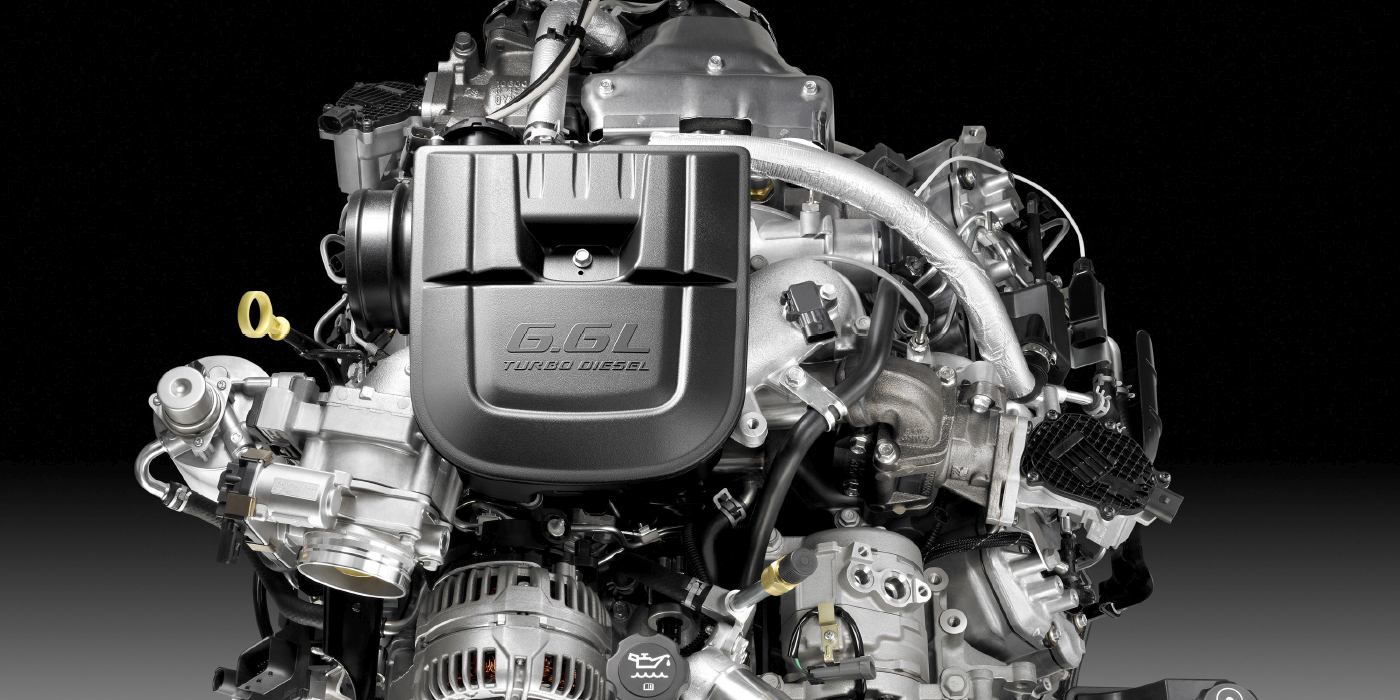

But, a funny thing happened on the way to the truck stop. Those voices shouting about how the new regulations would kill horsepower and torque subsided as the technology actually was shown to work. Sure, there were (and still are) detractors who won’t have anything to do with the new engines and, therefore, only specialize in the older models that can be more easily “tuned” for power and a big plume of black smoke. We’re not going to judge.

The new regulations are not perfect, but they enabled engine manufacturers to make their engines not only more powerful but also operate within the reduced emissions requirements for oxides of nitrogen (NOx).

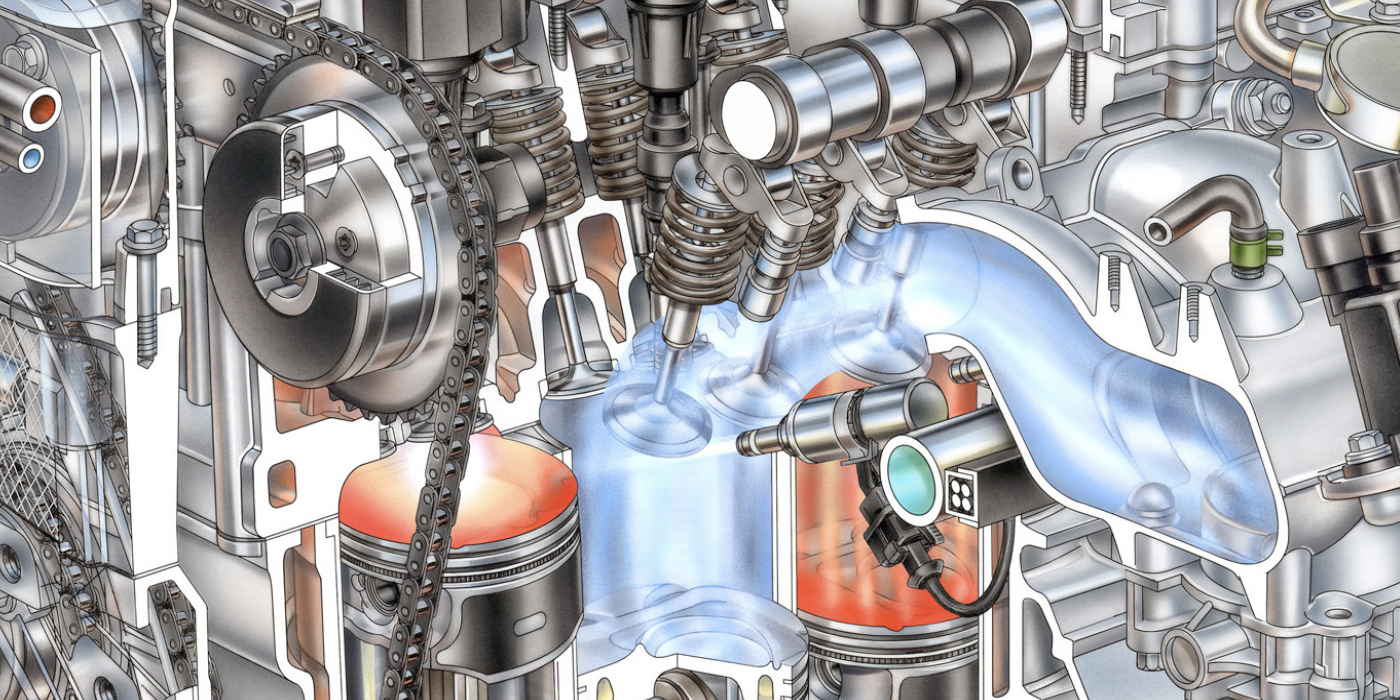

Using selective catalyst reduction technology lifted mainly from the agricultural industry, engine manufacturers were able to increase fuel efficiency and reduce NOx emissions. The modern diesel exhaust aftertreatment system is designed to reduce the levels of hydrocarbons (HC), carbon monoxide (CO), oxides of nitrogen (NOx) and particulate matter remaining in the vehicle’s exhaust gases.

Charles Culverhouse, CEO of Old World Industries, makers of BlueDEF and Peak automotive chemicals, told CNET: “Diesel exhaust fluid [DEF] works and it’s made from commonly available ingredients that are already being produced in vast amounts for the agricultural industry. The infrastructure is already in place.”

Reducing emissions to acceptable levels is achieved through a four-stage process using urea (basically, synthetic urine) that is injected into the exhaust before the selective catalytic reduction

(SCR) stage.

The close-coupled diesel oxidation catalyst (DOC) removes hydrocarbons and carbon dioxide through an oxidation process. Within the SCR, NOx is converted to nitrogen (N2), carbon dioxide (CO2) and water vapor (H20) through a catalytic reduction mixing with the DEF.

“The latest generation of DEF-based aftertreatment systems are built on nearly a decade of heavy-duty industry experience with DEF,” Jim Nachtman, heavy-duty marketing director for Navistar, told Fleet Equipment. “These systems are refined, providing cleaning intervals of 600,000 miles or more.”

Diesel engine manufacturers discovered they could fine-tune the engines first then allow the SCR and DEF to remove the remaining particulates. The engines are built for performance first and then the SCR, DPF and DEF take care of the rest. Another benefit of SCR technology is that engines get better fuel mileage compared with other systems for reducing particulate matter. Fuel mixed in with the SCR finds an added source of elements to burn, and mileage can be improved by as much as 5 – 7%.

With a standard 32.5% solution of DEF, fuel will crystallize and freeze at 12 degrees F. When the DEF solution thaws, it does not become diluted or overly concentrated. Freezing and thawing cycles have no impact on the grade of the product. DEF expands when frozen as much as 6.5 – 7% by volume. The packaging allows for leeway for freezing periods.

On cold days below 12 degrees F, DEF will freeze in the tank, but the SCR is designed to heat the tank and supply lines quickly.

Heat is more damaging, however. DEF starts to decompose at 86 degrees F, so if any is stored in the vehicle and you forget about it over several hot days, the fluid can become unstable and decompose. DEF that is diluted to less than 32.5% urea can be damaging to the SCR in some cases.

DEF manufacturers say it can last up to two years if stored properly at ambient temperatures of 75 degrees F as long as it is not exposed to prolonged periods of 86 degrees F or higher. Otherwise, the DEF will last about a year.

On engines such as the 6.6L Duramax, the ECU uses two smart NOx sensors to control exhaust levels. The first NOx sensor is located at the turbocharger outlet and monitors the engine output NOx. The second sensor is located in the exhaust pipe downstream of the SCR and monitors NOx levels exiting the aftertreatment system. The smart NOx sensors communicate with the ECU to quickly bring the sensors to operating temperature. Any moisture remaining in the exhaust system could interfere with sensor operation. There is a delay turning on the heaters until the exhaust temperature exceeds a calibrated value. This allows any moisture remaining in the exhaust to boil off before it can affect NOx sensor operation.

As the exhaust temps rise, the heat converts the urea into ammonia (NH3) that reacts with NOx to form nitrogen, CO2 and water vapor. The optimum NOx reduction occurs at SCR temperatures above 480 degrees F on Duramax engines. At lower temps, the conversion of urea forms sulfates that can poison the catalyst. To prevent this from happening, the ECU suspends the DEF injection when exhaust temperature falls below a

calibrated limit.

If the vehicle is not driven within the parameters necessary to initiate a normal regeneration cycle, drivers will most likely be greeted with a “service engine light” and possibly a “reduced engine power” message on the dash if soot buildup is above the calibrated value. The vehicle will remain in the reduced power mode until a technician performs service regeneration. If the ECU detects that the “soot load” is too high to be burned off without possible thermal damage to the DPF, then ECU takes control of engine operation until the service regeneration is completed. On the 6.6L Duramax, for example, this function takes about 35 minutes to perform using a scan tool.