Did you ever wonder where a chemistry or physics class could come in handy inside the repair bay? The knowledge from these studies could actually help you understand a perplexing problem with a fuel delivery system.

If you could build a large enough oxygen sensor and the difference in oxygen was great enough between the air inside and outside the sensor, it would generate electricity. The larger the sensor, the more power generated. It is a lot like the basic principle of a fuel cell used in the Apollo rocket program.

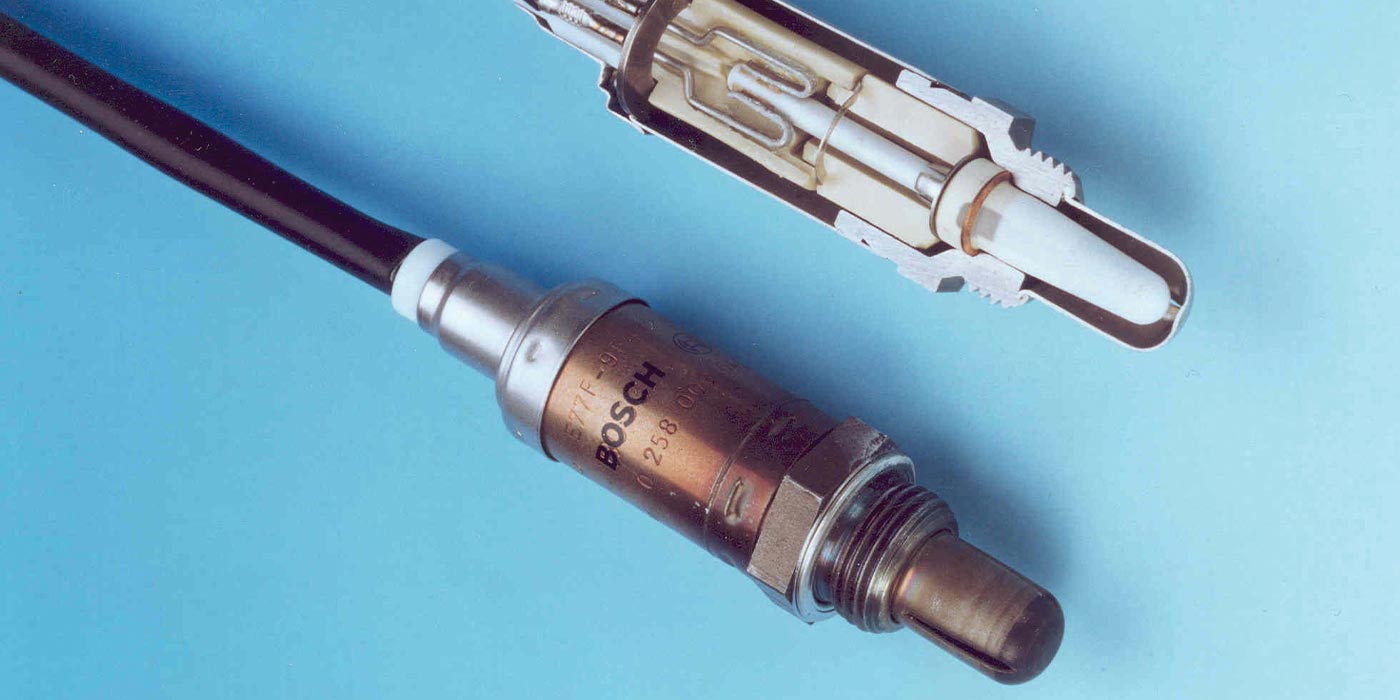

An oxygen sensor is made of zirconium oxide (ZrO2), a chemical compound used to form the sensor’s thermal-driven electrochemical fuel cell. Energy is generated by the difference of oxygen inside compared to the outside.

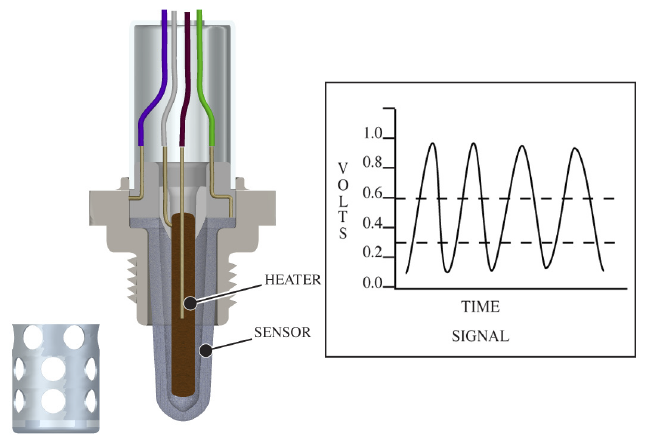

Two platinum (Pt) electrodes are placed on the ZrO2 to provide a connection for output voltage to a control module. An output voltage of 0.2 V (200 mV) DC represents a lean mixture where there is a lot of oxygen in the exhaust stream. A reading of 0.8 V (800 mV) DC represents a rich mixture where there is little or no oxygen in the exhaust stream. The ideal point is 0.45 V (450 mV) DC – this is where the quantities of air and fuel are in the optimum – or stoichiometric – ratio.

The controller uses 450 mV as a midpoint in a voltage range to control fuel trim for the injector pulse cycle. The sensor’s analog input to the controller is converted to a digital rich or lean command to drive a fuel trim software program. Sometimes referred to as “Block Learn,” it adjusts the cycle time of the fuel injector. The voltage generated by the sensor must be greater or less than the voltage of the damping zone to send a rich or lean signal to the controller.

The damping zone acts like a shock absorber on a suspension to prevent the voltage signal from oscillating. A planar air fuel sensor is a combination of a standard zirconium oxide oxygen sensor and a pump cell to maintain a constant sensing of a stoichiometric air fuel ratio through the extreme rich and lean conditions. The pump cell is a diffusion gap in the zirconium oxide of the sensor that is connected to a control circuit.

The pump cell controls the oxygen concentration of the sensor by adding or subtracting oxygen to the diffusion gap. Input to the electronic circuit modifies the oxygen concentration by changing the polarity of the current flow in the pump cell. The changing polarity of the input and trim current flow causes the control circuit to send a rich or lean signal to the engine control module.

Who says auto repair isn’t rocket science?