Driveshaft problems can be spotted from the moment you put the vehicle in gear to pull it into a bay. As the power is transmitted from the transmission to the rear axle, the slack from worn or damaged components is taken up, resulting in a sudden crunch or pop.

Once the vehicle is moving, you might hear a whine coming from the center of the vehicle. The noise will change as speed increases and might change as power is applied. If the vehicle is put into neutral, the sound remains the same.

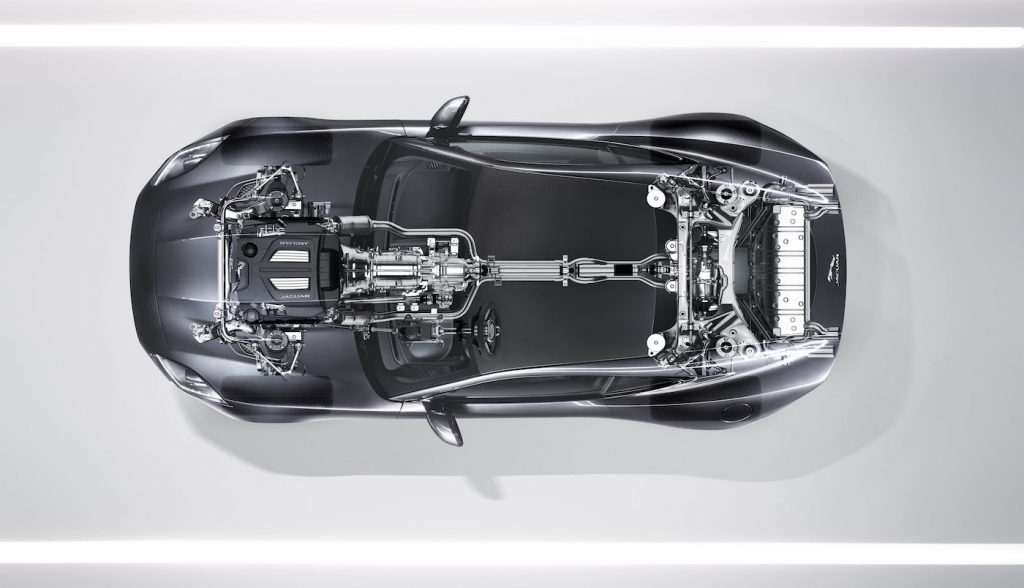

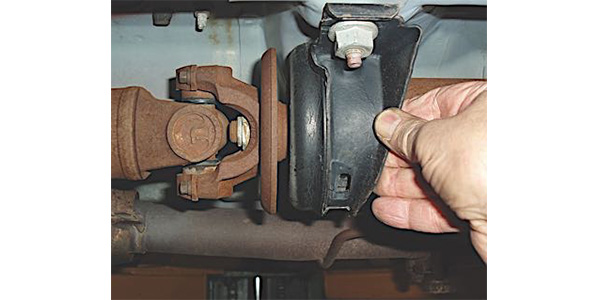

The problem could be the center bearing’s support. These are used if the driveline has a two-piece driveshaft. The center bearing is a ball bearing mounted in a rubber cushion that attaches to a frame crossmember.

The cushion allows vertical motion at the driveline and helps isolate the vehicle from vibration. The bearing in most center support is sealed for life. Some do have a zerk fitting from the factory, and some replacement units also have a way to lubricate the bearing.

Premature failure of the center bearing could be the result of too much driveshaft angle, the water shield being missing or damaged, road salt and moisture, or damaged rubber casings. Also, high mileage and bearing wear can contribute to premature wear.

A small amount of noise is normal when using 4WD on a low-traction surface such as snow, ice, mud or sand. When operated in 4WD on a high-traction surface, such as clear pavement, the noise generated may be much more significant. This noise is the result of “driveline loading,” which can naturally occur in 4WD.

As a vehicle travels down the road, the tires rotate a certain number of times per mile depending on the tire circumference. If all the tires are not exactly the same circumference, they will turn at different rates. On these trucks, 4WD is a “part-time” system designed for use only on low-traction surfaces.

This system has no internal differential, so the front and rear propeller shafts will turn at the same speed.

On low-traction surfaces, different tire sizes won’t have much effect, as one tire can easily slip on the road surface to match the speed of the other tires.

On a high-traction surface, it is much more difficult for one tire to slip. Therefore, the 4WD operates under a “blind” to heavy-load condition, and noise is the result.

As tire rolling rates are a major factor in this condition, consider the following essential items:

• All tires should be the same size and brand (excluding the spare tire). Tires of different brands may have different circumferences, even if they are the same size;

• Check that tire pressure is equal in all four tires. A tire with low pressure will roll at a different rate;

• All tires have approximately an equal amount of wear. Tires with varying amounts of wear will roll at different rates; and

• Ensure that all tires are the same tread type. Don’t mix on- and off-road, all-season or street tires on the same truck, as they may have different circumferences and roll at different rates.

Driveline noises caused by loading in 4WD vehicles may be mistaken for transfer case or front axle noise because they can sound very similar. 4WD noise caused by loading may exhibit the following conditions:

• The noise will be greatest on a clear, dry road and decrease on a low-traction surface. Front axle or transfer case noise caused by bearing, ring, and pinion, or planetary gearing will be the same on all surfaces;

• The sound will increase while making a tight turn. Most front axle or transfer case noises won’t increase;

• The noise can be changed from a deceleration condition to acceleration (or acceleration to deceleration) by raising or lowering tire pressure at one end of the vehicle; or

• One or more of the tires may show small, short scratches around the circumference of the tire tread. These scratches are caused by the tire slipping, or “scuffing,” on the road surface.

This noise should be considered normal and attempting to repair it will not result in satisfactory reductions to driveline noise. Any attempts to correct this condition by repairing these components may cause the customer to believe that the vehicle is unreliable and will also result in an inconvenience while their vehicle is out of service.