PC-11 will now define two separate heavy-duty diesel lube oils. PC-11A (which will likely be called API CK-4) is scheduled to be commercialized in March 2017. This oil performance category will address pre-2017 engine designs and all the various XW-40 and XW-30 grade oils on the market since much is known about their actual field performance. All the necessary laboratory engine tests needed to define API CK-4 diesel performance have been developed, and labs are currently installing and calibrating dynamometer test stands.

Lighter oils designed for use in 2017 and beyond diesel engine designs will be addressed by a PC-11B spec, which has not yet been finalized or named. The oil industry wants to change the current API naming protocol so these oils cannot be confused with PC-11A or API CK-4 oils to prevent oil misuse and possible engine failures. Current thinking is that they will be called API CF-4 (the “F” is for fuel economy). However, this is not yet finalized.

Why shouldn’t PC-11B oils find a way into pre-2017 engine designs?

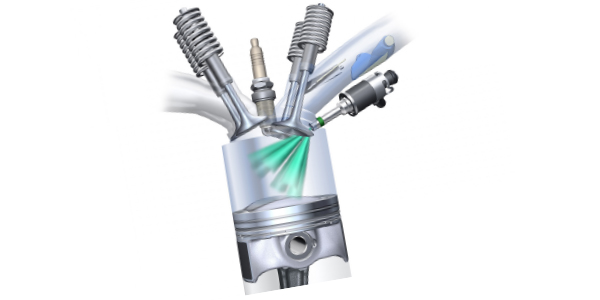

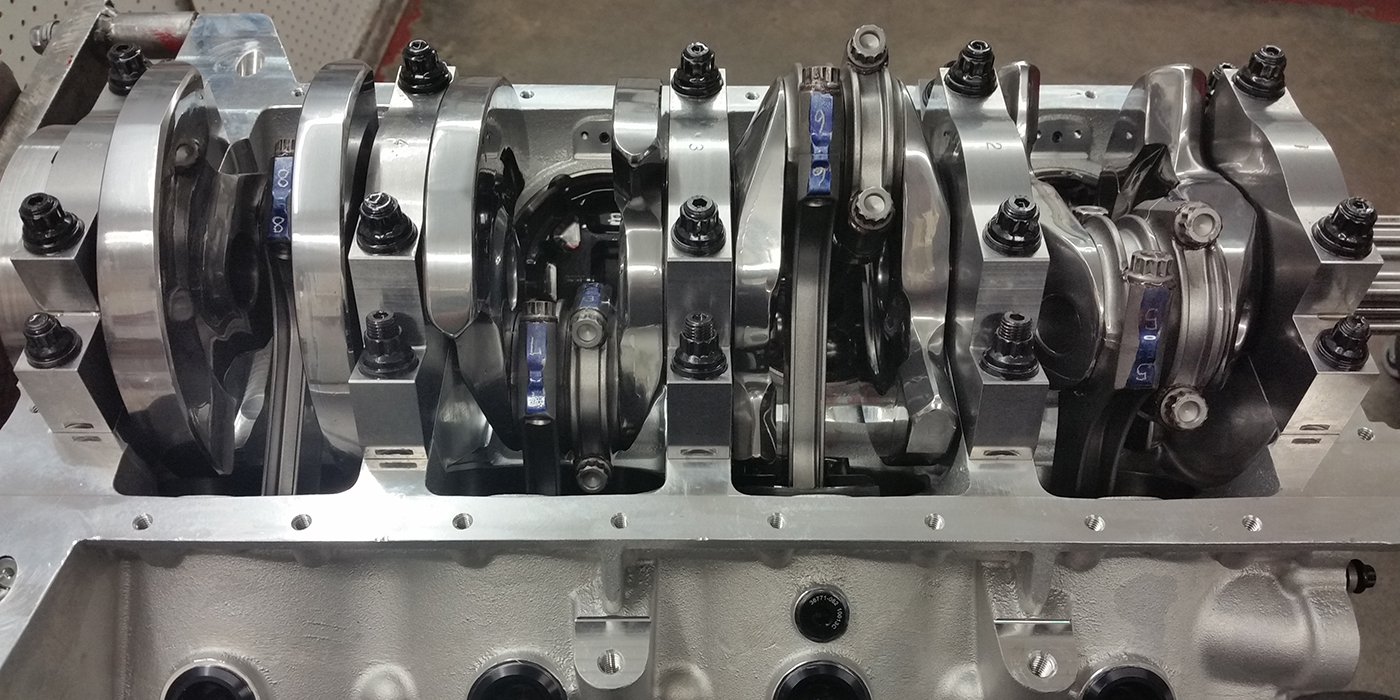

First, we are used to categorizing oils only by the viscosity grade, but viscosity merely defines an oil’s resistance to flow. Viscosity doesn’t define such things as density, volatility or shear strength. Engine components require an oil film to be present between surfaces to prevent metal-to-metal contact, but viscosity grade doesn’t accurately guarantee that an oil film will be present on a hot engine component when it is needed.

Years ago, additive manufacturers and oil suppliers observed that shear stability was a reasonable indicator of film strength. A high-temperature high-shear (HTHS) test was developed to better delineate shear performance at hot engine temperatures. As we gain experience with HTHS testing of lighter oil formulations, we will be better able to formulate even thinner engine oils, which will improve fuel economy, yet still adequately protect engine components.

Oil formulators also know that volatility, or the oil’s propensity to evaporate at higher temperatures, is also a valuable piece of the equation. No matter how viscous or how shear-stable an oil is, oil can’t protect engine components if it evaporates off surfaces at higher operating temperatures. On the other hand, if the light ends were to evaporate off an oil, would the remaining heavy ends still improve fuel economy or not?

PC-11B is trying to investigate all the above factors and adequately define thinner viscosity grade diesel engine oils which will offer end users improved fuel economy without sacrificing engine service life. Passenger cars’ oils are advanced in this respect. Honda has recommended new viscosity grades (SAE 8, 12, and 16) to describe thinner oils for use in gasoline engines.

The PC-11A spec is much better understood due to vast experience with typical commercially available diesel engine oils. API CK-4 will require oils to have a minimum 3.5 cPa HTHS test result and a minimum NOAK volatility test result of 13-15% evaporated. Considerable field test experience is behind these recommendations.

PC-11B requirements, on the other hand, are still firming up. Current thinking is that HTHS test minimums will be 2.9-3.2 cPa. These will finalize as diesel engine builders gain more laboratory and field test experience. NOAK volatility limits on oil evaporation will also be finalized when more is known about actual diesel engine performance when using very thin oils.

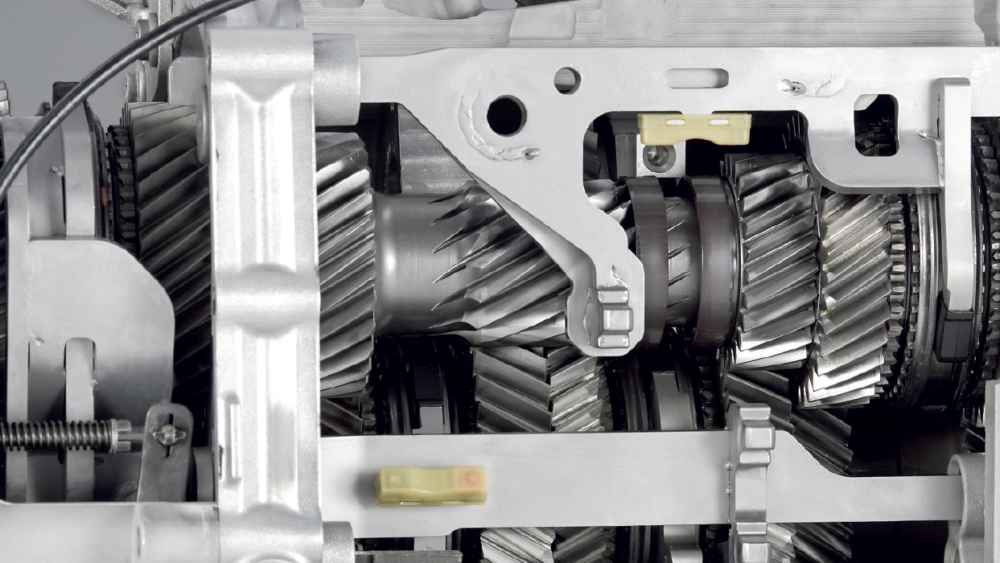

Although much is known about the lubrication of NASCAR and NHRA engines with very low viscosity oils, three factors keep this information from translating directly to heavy-duty diesel truck engines.

It isn’t easy to reconfigure engines to live well on very light engine oils, particularly if the surfaces to be lubricated are of the same metallurgy. That’s why cam and lifter metallurgy is so important, and you can’t run a steel distributor gear on a steel camshaft. You can decrease adhesive bonding significantly by switching to dissimilar materials such as bronze and steel.

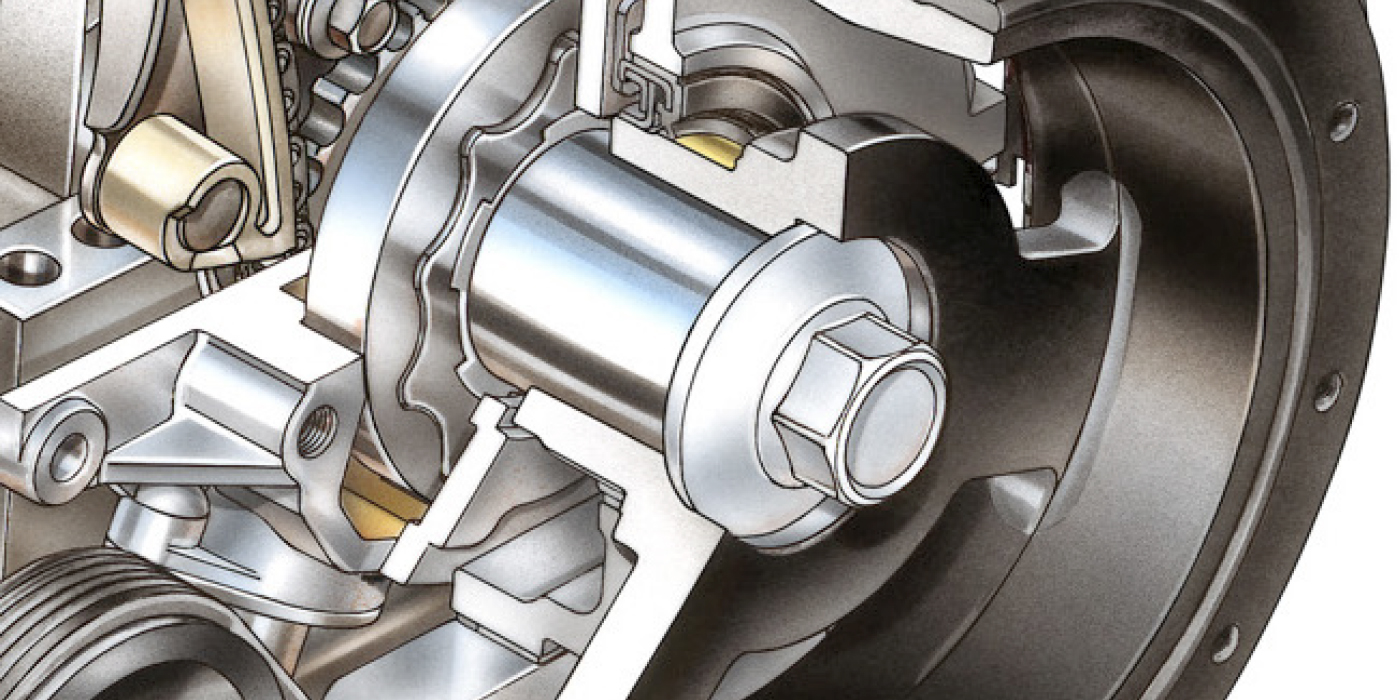

Inadequate oil pressure is also a problem when trying to run extremely low viscosity oils. Although crank and rod bearings can survive on much lower oil pressure than most people believe, cam lobes, fuel pump pushrods, timing gears, and some distributor gears depend on oil being squirted onto those surfaces to survive. Low oil pressure reduces the pressure used to squirt oil onto those components.

So, what determines how much oil pressure a given engine makes besides the viscosity of the oil? In my mind, oil pressure depends on the output of the oil pump minus the controllable leaks in various engine components. Decreasing rod and main bearing clearances and connecting rod cheek clearances can be used to raise oil pressure, but can all the other “leaks” in the engine be resized accordingly? And what effect do valve clearances have on oil pressure?

The point of all this discussion is that much diesel engine development work will be required before diesel engines can utilize significantly thinner oils than are available today. Current engine designs will operate satisfactorily on the PC-11A (API CK-4) diesel oils, but don’t utilize the PC-11B oils unless you are operating in a very cold environment like Alaska. Also, never use an engine oil that says, “For gasoline engines.”