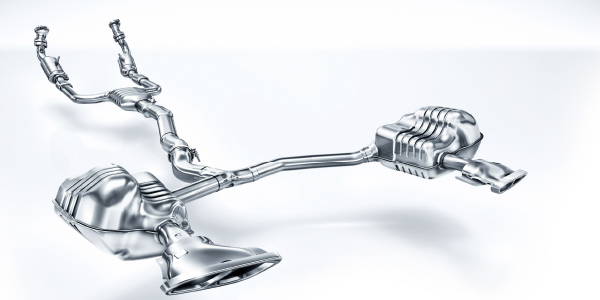

Bosch celebrated the production of the 500 millionth oxygen sensors in May. For 32 years, this vital component has played a major role in reducing automotive emissions. Placed in the exhaust gas flow of an internal combustion engine, the automotive oxygen sensor measures the oxygen content in the exhaust stream. This information is required by the engine management system for accurate control of the air/fuel mixture. Apart from allowing combustion that is as clean and complete as possible, it is only with this sensor that a catalytic converter can be used for efficient exhaust gas treatment.

Bosch celebrated the production of the 500 millionth oxygen sensors in May. For 32 years, this vital component has played a major role in reducing automotive emissions. Placed in the exhaust gas flow of an internal combustion engine, the automotive oxygen sensor measures the oxygen content in the exhaust stream. This information is required by the engine management system for accurate control of the air/fuel mixture. Apart from allowing combustion that is as clean and complete as possible, it is only with this sensor that a catalytic converter can be used for efficient exhaust gas treatment.

Bosch invented and started series production of automotive oxygen sensors in 1976. Ten years after its launch in the U.S. variant of the Volvo 264, Bosch celebrated delivery of the 10 millionth oxygen sensor. By 1993, this figure was already 50 million, and by 2001, 250 million. In the meantime, the company produces roughly 5,000 oxygen sensors per hour worldwide – some 45 million every year.

Since 2002, the oxygen sensor has also been employed in diesel engines, where it meters the amount of fuel injected more precisely, even further reducing emissions.

The Bosch lead plant in Rutesheim, Germany, works very closely with manufacturing sites in the U.S., China, and Korea. Moreover, Bosch operates sensor element production facilities for planar sensors in Bamberg, Germany, and Anderson, SC. At the same time, the international manufacturing network offers reliable deliveries worldwide that dovetail with customers’ manufacturing cycles.

"The importance of oxygen sensors will further increase in the future. Continued intensification of emission limits, tight installation space conditions, ever-increasing fuel prices and stricter requirements for metering accuracy and durability continuously drive further developments at Bosch," says Wolf-Henning Scheider, president of the Gasoline Systems division at Robert Bosch GmbH.

From a Simple Principle to a Multifunctional Exhaust-Gas Sensor

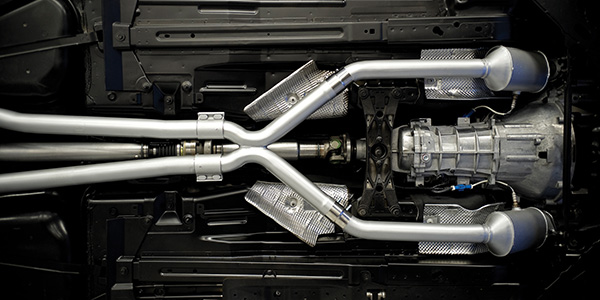

Placed upstream of the catalytic converter (and occasionally also downstream of it), oxygen sensors measure the oxygen content in exhaust emissions – an indicator of the combustion quality. The full combustion of 2.2 lbs (one kilogram) of gasoline requires roughly 32 lbs (14.5 kilograms) of air. The ratio of air drawn in to the volume of air required is called the value.

Conventional gasoline combustion processes operate with a lambda value of 1. If the lambda value is lower than 1, the mixture is rich and combustion takes place with oxygen deficiency. If the value exceeds 1, lean combustion with excess oxygen takes place – combustion of the kind found in diesel engine and lean-mix gasoline engine designs. With the so-called switching-type sensor, which provides a discrete sensor signal when combustion passes from lean to rich, the stoichiometric point (14:1 air/fuel mixture) can be set precisely. Wide-band sensors, which provide a constant measurement signal over a wide lambda range, from rich to lean, enable even more precise regulation of air/fuel values.

Bosch’s wide-band sensor also makes it possible to record air/fuel values selectively by cylinder. Diesel engines and lean-mix gasoline engines require wide-band sensors to accurately meter injection quantities and to activate the regeneration of NOx storage catalytic converters or lambda-based exhaust gas recirculation systems.

Bosch offers the right sensors for all applications and engine types: the LSU planar wide-band sensor for gasoline, diesel and gas engines, and the LSF planar sensor for gasoline engines. Further models include the LSH and LSS finger sensors for gasoline engines. The use of high-quality materials and perfected production techniques ensures long service life and high signal accuracy.

For information on Bosch automotive aftermarket products, visit www.boschautoparts.com.