TSB Number: 08-BE-004

Excessive resistance in high-amperage circuits may result in one or more of the following symptoms:

• Blower motor speed slows down and the radio cycles off and on.

• Intermittent headlight dimming during deceleration.

This bulletin provides the procedure to diagnose and repair the vehicle wiring grounds.

Service Procedure:

1. Start the vehicle and turn on the headlights (including high beam), air conditioning and set the blower to maximum speed.

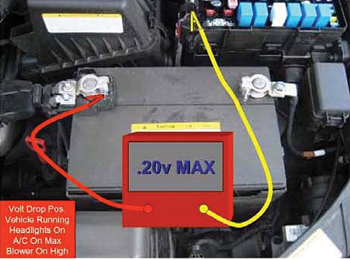

2. Using a digital volt-ohm meter (DVOM), perform a voltage drop test on the positive battery cable, paying particular attention to the leads to the underhood junction box (refer to top photo). If the voltage drop is more than 0.2 volts on any of the leads, replace the positive battery cable.

3. Perform the voltage drop test on the negative battery cable. If the voltage drop is more than 0.2 volts, repair or replace the negative battery cable.

4. Perform the voltage drop check to all body ground locations in the engine compartment. Check with the positive DVOM lead on the negative battery terminal and the negative lead to the ground locations. If the voltage drop is more than 0.2 volts, repair or replace the body ground terminal and/or wiring assembly.

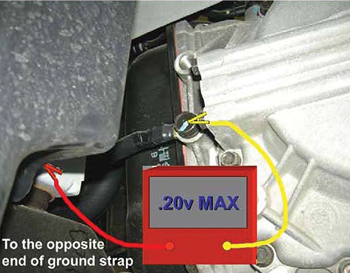

5. Perform the voltage drop check to all Engine and Transmission ground straps. (see bottom photo). Check with the voltmeter positive lead on one end of the strap and the negative lead to the opposite end. If the voltage drop is more than 0.2 volts, repair or replace the ground terminal and/or ground strap.

Courtesy of ALLDATA.