Situation

A commercial vehicle — a 1996 Chevrolet 3500 van — was recently brought in for service with the customer complaining of low fuel pressure. The vehicle had recently had its fuel module and fuel pressure regulator replaced, due to a low fuel pressure concern and the vehicle was still experiencing the same issue.

Procedure

On further review of the fuel module and pressure regulator, it was determined both parts to be fully functional. Starting the vehicle, the fuel pressure was reviewed at the engine fuel rail, which was registering 38 psi. The value was well below the specification of 55-62 psi.

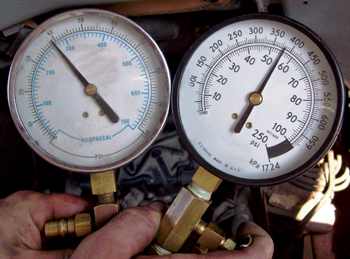

To validate the fuel pressure gauge, a second fuel pressure gauge was connected to the engine and the two pressure gauges were compared.

On inspection, the first fuel pressure gauge being used for diagnostics was reading 17 psi lower than it should, which caused inaccurate readings and misdiagnosis of vehicles. On noting the problem, the fuel pressure gauge was replaced. There were no issues with the fuel pump or pressure regulator once the correct gauge was installed.

A good rule of thumb is “we are only as good as the tools we use to service.” Make sure your diagnostic equipment is up-to-date. It could save you unwanted comebacks in the future.

Courtesy of Delphi.