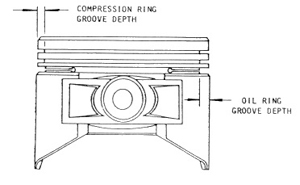

It is extremely important to check rings for sufficient back clearance to verify correct ring set application for the engine.

The piston ring set and the piston must be engineered to complement each other from a standpoint of clearance between the back of the piston ring and the bottom of the piston groove. This clearance is referred to as back clearance. If the clearance is not sufficient, severe engine damage can result when the piston and rings are installed in the engine.

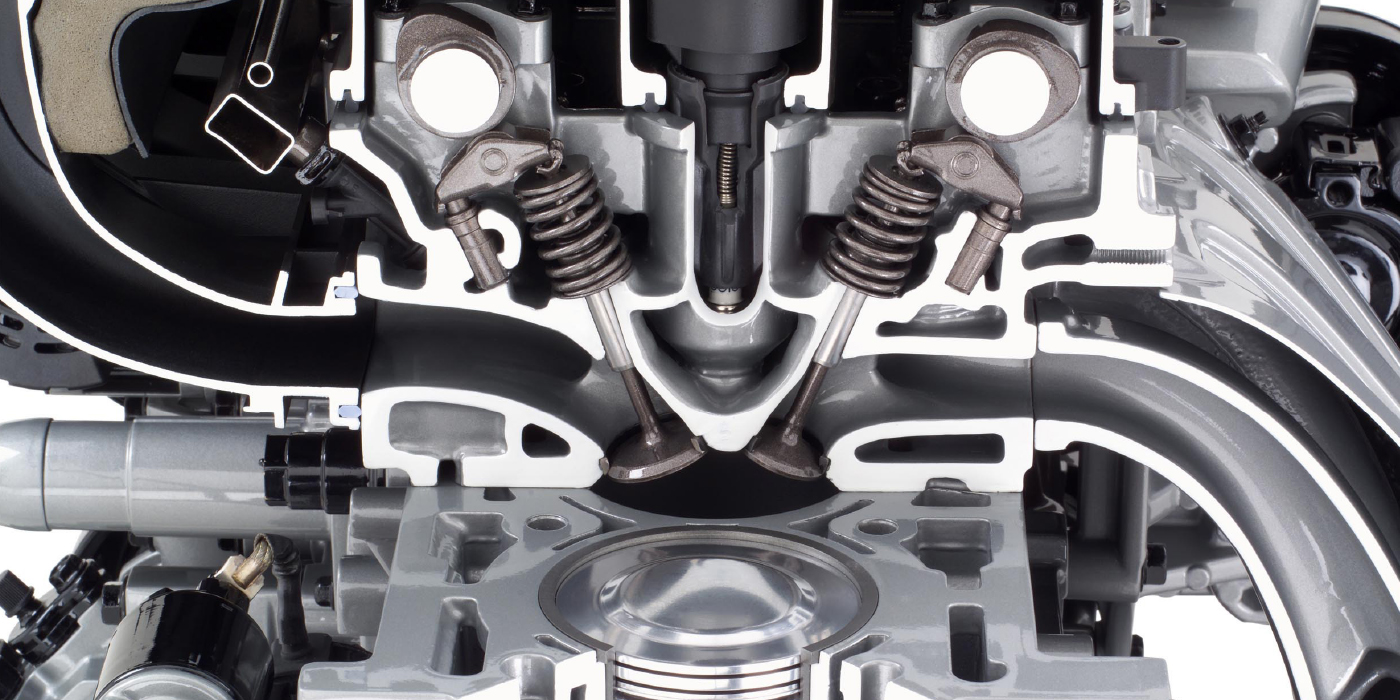

The sketch in Figure 1 illustrates groove depths of a piston.

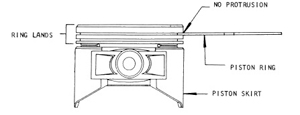

It is simple to check compression ring back clearance. Place the outer diameter (O.D.) of the piston ring fully into the piston groove as illustrated in Figure 2. No portion of the inside diameter (I.D.) should protrude beyond the piston land.

Oil rings are more difficult to check. However, by placing the oil rails and expander together as they would be assembled and inserting as shown, it can determine if back clearance exists. Minimum clearance should be .0 15˝.

Pistons are designed to have considerable more clearance in the ring land area than in the skirt area. Be sure the ring or ring assembly does not protrude beyond the groove lands. The designed in head clearance will ensure sufficient clearance behind the ring when the piston is installed in the cylinder.

In situations where piston grooves are deeper, the oil ring can be difficult to install because the oil ring assembly tends to "pop off" the piston. Once the rings are installed, however, they will perform properly even though there is more than normal back clearance. Some engine manufacturers have changed piston dimensions within an engine model making it necessary to catalog two piston ring sets, deep groove, and shallow groove within one engine model.

Source: Hastings Piston Rings.