This may be due to corrosion/sediment buildup in the water reservoir. This buildup may also cause the drain plug to stick making drain plug removal difficult.

It’s not necessary to replace the HFCM. There is a new fuel manifold (3C3Z-9B249-AB) available, which will correct the condition.

Service Procedure:

Warning: Smoking or open flame of any type must not be present when working near fuel or fuel vapor.

1. Disconnect both battery ground cables.

2. Raise and support the vehicle.

Note: Illustrations are of late-build models, early-build models are similar but may differ slightly.

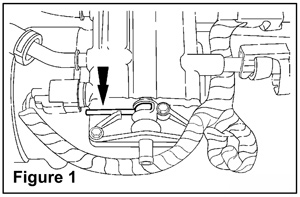

3. Open the fuel/water separator drain valve to release the fuel pressure (see Figure 1).

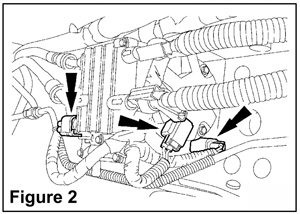

4. Disconnect the fuel pump, fuel warmer and water-in-fuel electrical connectors from HFCM (see Figure 2).

5. Disconnect the fuel hoses from HFCM:

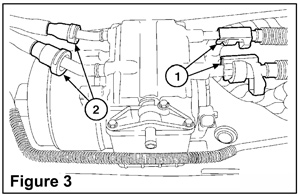

a. Remove the fuel hose retaining clips and discard. Disconnect the fuel hoses from the fuel pump (see Figure 3 – #1).

b. Press in the retaining clips and release the fuel hoses (see Figure 3 – #2).

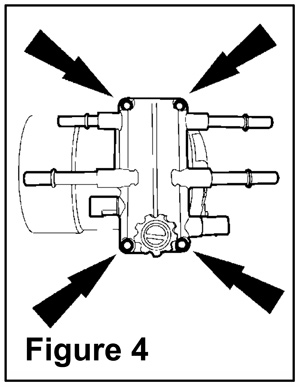

c. Remove the screws and the old fuel manifold cover (see Figure 4).

6. Inspect/clean any debris from the HFCM water reservoir housing (max. 25 psi air).

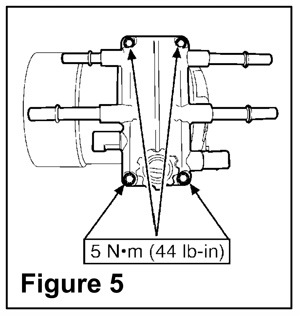

7. Install the new fuel manifold and screws (see Figure 5).

a. Tighten the screws to 44 in.-lb. (5 Nm).

8. Reinstall all electrical connectors and fuel lines to the HFCM.

9. Verify that there are no fuel leaks from the HFCM.

10. Drive the vehicle to verify your repair.

Courtesy of Ed Dorowski, ALLDATA editor and Jeff Webster, ALLDATA technical writer.