By Gene Markel

By Gene Markel

Contributing Editor

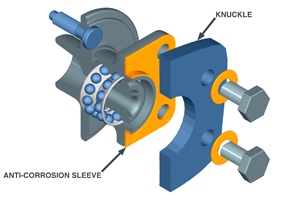

Conventional steel control arms and steering knuckles are being replaced with aluminum to reduce vehicle weight and increase fuel economy. This type of knuckle has been in service for more than a decade and some problems with corrosion are being reported from the field.

Aluminum is 65% lighter that steel and aluminum forgings and alloys can have the same structural strength as the steel component. This positive is offset by the negative of galvanic corrosion.

Galvanic corrosion occurs when there is contact between dissimilar metals in the presence of an electrolyte. One of the metals becomes the anode that gives up electrons and corrodes faster than it would alone. The other becomes the cathode that accepts the electrons and corrodes slower than it would alone.

For galvanic corrosion to occur, three conditions must be present: Electrochemically dissimilar metals must be present; these metals must be in electrical contact; and the metals must be exposed to an electrolyte. This often occurs between radiators, engine blocks and aluminum housings on water pumps.

In the case of the steering knuckle, the metals are aluminum and steel. The electrolyte is a mixture of sodium chloride (salt) and water.

There are several methods of preventing galvanic corrosion. Anodizing increases the thickness of the natural oxide coating on aluminum to provide corrosion resistant surfaces and preparation for additional protective finishes if needed.

Chemical conversion coatings are layers of a metal oxide, phosphate or chromate compounds. Conversion coatings are less expensive than anodizing and provide a good base for paint. Powder coating is used by some automakers and is another method of corrosion protection that can be added to an anodized or conversion coated surface.

To prevent galvanic corrosion on aluminum suspension components, especially steering knuckles, it is important not to damage the protective coatings applied to the knuckle or the insulating bearing sleeve.

Some bearing manufacturers include a corrosion-protective paste to some wheel bearing hub units that is to be applied between the hub and knuckle. Also, some vehicles have a shim or sleeve that goes between the hub and knuckle. If the shim is damaged, it must be replaced or the resulting corrosion may result in the structural failure of the knuckle.