Vehicle: 2006 Jeep (XK) Commander.

Overview:

This bulletin involves cleaning the HVAC blower wheel or replacing the blower motor assembly and resealing a cowl stud head.

Symptom/Condition:

The vehicle may exhibit vibration from steering wheel and/or instrument panel when the HVAC blower is operated. The blower motor may be out of balance due to a tar mastic patch stuck on the blower motor fan wheel.

Diagnosis:

1. Turn the ignition to the on position. Do not start the engine.

2. Place the windows in the full up position.

3. Open the glove box.

4. Separate the glove box damper rod from the right side of the glove box by sliding the rod towards the rear of the vehicle to release it from the bin.

5. Open the glove box and carefully use fingers to press down on the glove box open stops at the top of the bin to allow the glove box to rotate down toward the carpet.

6. Rotate the box down and release the door hinges at the bottom and remove the glove box.

7. Turn blower motor on. Starting at the low speed, cycle blower motor through each speed for 30 seconds.

8. While blower motor is being tester per step 7, place your hand on blower motor housing to verify if vibration is coming from blower wheel.

9. If vibration is coming from blower, perform the Repair Procedure.

Repair Procedure:

1. Remove the silencer panel below the glove box.

2. Remove the blower motor wiring connector from the resistor/power module.

3. Remove the three screws attaching the blower motor to the HVAC housing.

4. Remove blower motor from HVAC housing.

5. Completely remove tar mastic patch from blower wheel if possible.

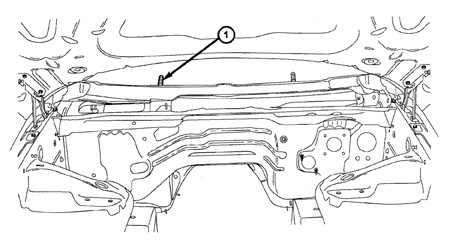

6. Locate the base of the cowl stud that the mastic patch came from and install a piece of duct tape over it to seal against wind noise (see Figure 1).

7. If tar mastic patch or tar cannot be completely removed from blower wheel, install a new blower motor assembly.

8. Tighten the screws to 2.2 Nm (20 in.lbs.)

9. Attach the blower motor wiring connector to the resistor/power module.

10. Install the silencer panel below the glove box.

11. Install the glove box.

Courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.