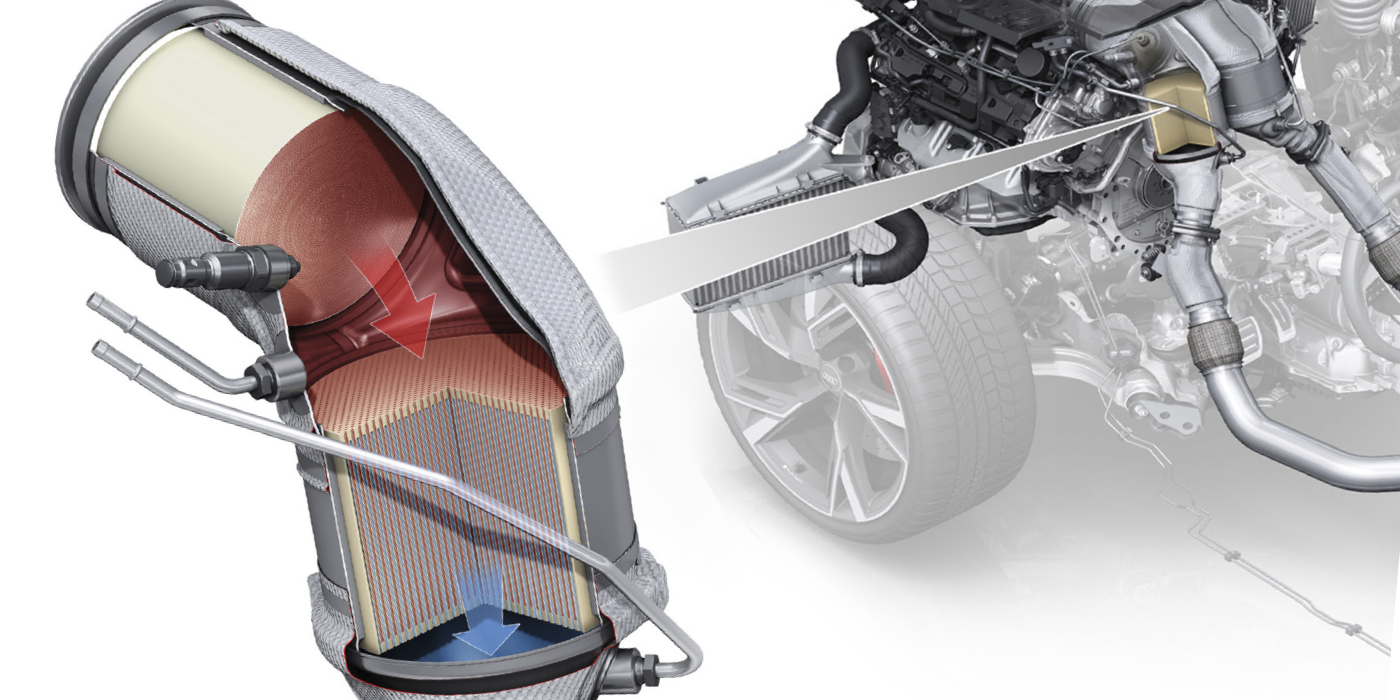

Under certain driving conditions, such as a lot of city driving, increased carbon deposits may cause the EGR valve to seize or jam in the open position. This can result in reduced performance for the car as the boost pressure leaks out via the EGR valve. In some cases, DTCs P0400, P0401 and P0402 may be generated.

Cleaning the EGR is usually sufficient to solve the problem.

Affected Models:

• Saab 9-3 (9400) with engine alternative D223L;

• Saab 9-3 (9440) with engine alternative D223L; and

• Saab 9-5 with engine alternative D223L.

Service Procedure:

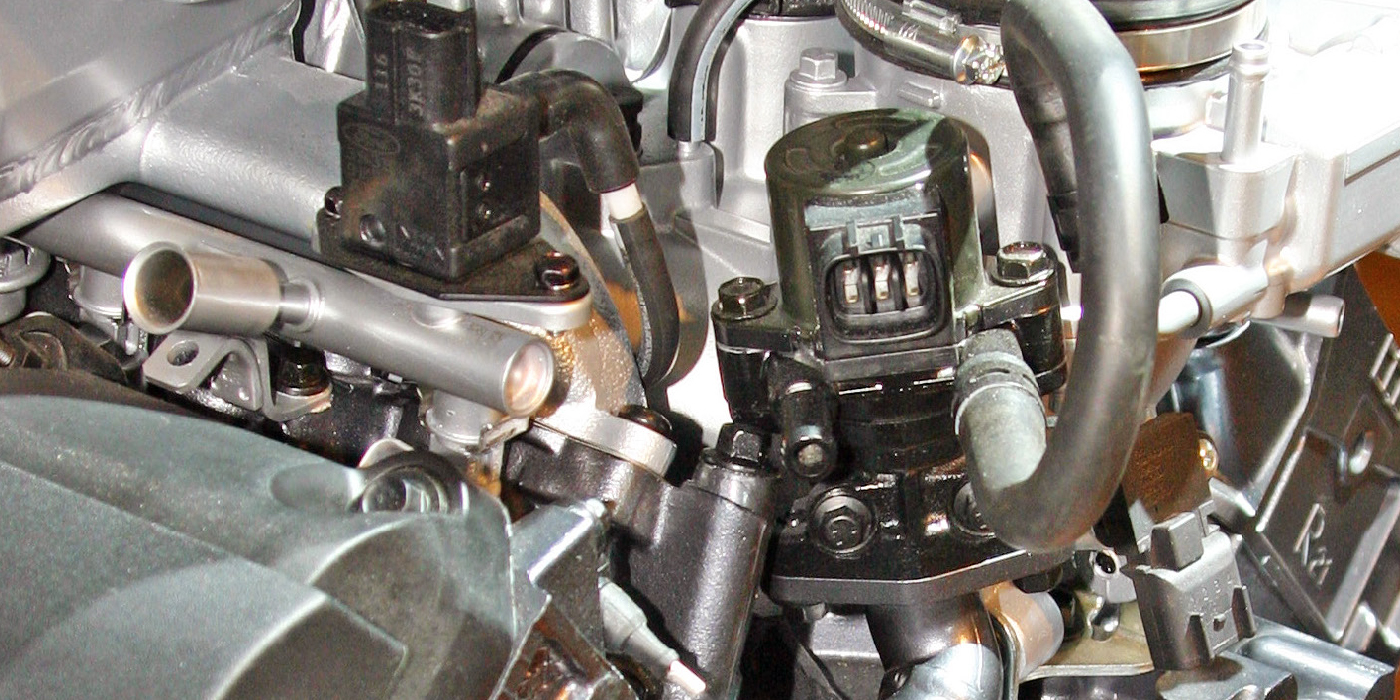

1. Remove the EGR valve in accordance with WIS – Model selection – Engine – Exhaust emission control system, diesel – Adjustment/Replacement – Control valve, exhaust gas recirculation 4-cyl. Check whether or not carbon has formed on the shaft that runs up into the valve.

2. Clean the shaft as necessary by spraying on a solvent, e.g. Brakleen degreasing agent, solvent naphtha or equivalent. Use a soft paintbrush to remove the carbon.

3. Chassis No. 12020000: Fit the EGR valve and clear and DTCs. Use a new O-ring. Test the engine at idle speed. Use Tech2: Diagnosis – Engine – EDC15 – Activate – EGR valve and check that the tone of the engine changes at activations. Test-drive the car.

Chassis No. 12020001: After cleaning, connect the EGR valve’s connector and test the valve separately before fitting. Use Tech2: Diagnosis – Engine – PSG 16 – Activate – EGR valve. Check that the valve closes/opens. Fit the EGR valve and clear any DTCs. Use a new O-ring. Test-drive the car.

Technical service bulletin courtesy of Mitchell 1.

For information on products offered by Mitchell 1, visit www.mitchell1.com.