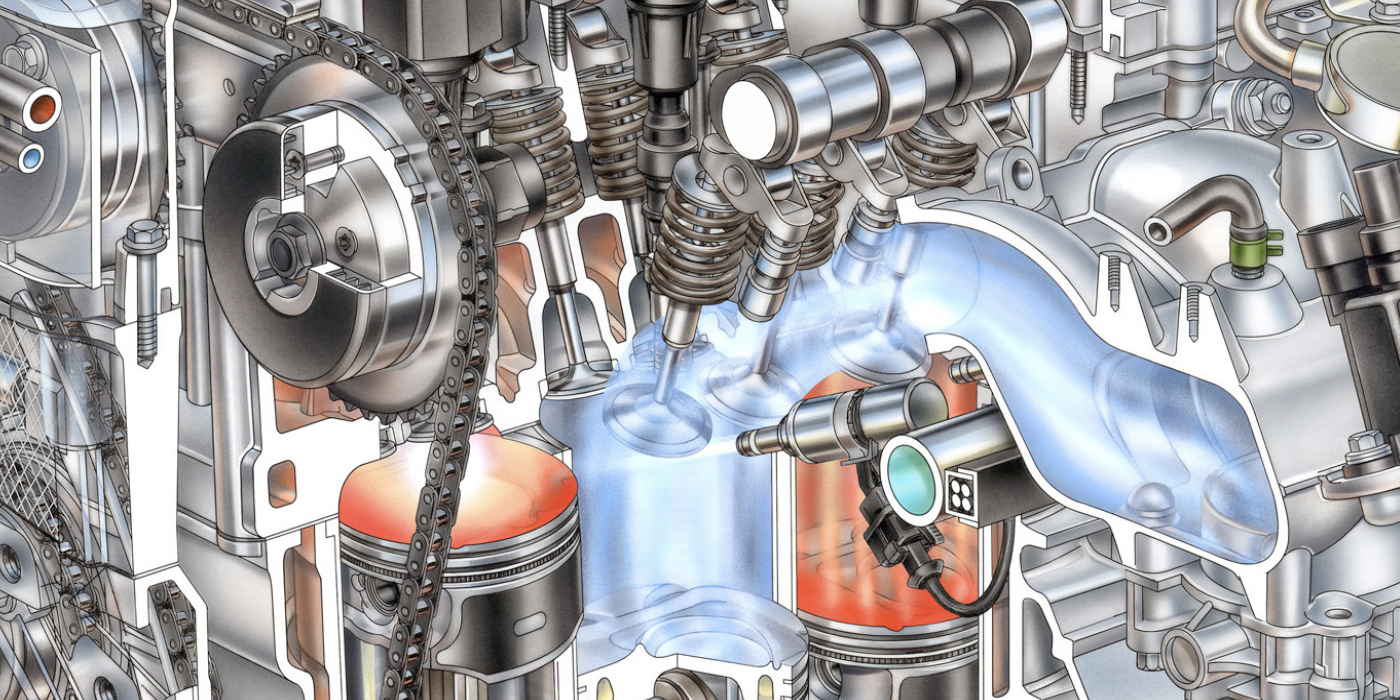

The EGR system module (ESM) is one of Ford’s latest EGR system for gasoline engines. It is an EGR valve, EVR, MAP and DPFE sensor rolled into one package. See Figure 1.

Though the DPFE sensor on an ESM is referred to as “DPFE” by the scan tool and also wiring diagrams, it is not a traditional DPFE sensor as used on the older EGR system. It is actually two separate MAP sensors. One MAP sensor is used to measure EGR flow after the EGR valve seat and before the flow restrictor built into the EGR base gasket. The other MAP sensor is measuring manifold pressure. The MAP sensor that is actually measuring manifold pressure serves slightly more of a purpose than to just help figure out EGR flow.

This MAP sensor is also used to calculate BARO at KOEO. This does not mean that BARO is solely calculated from this MAP sensor. The Ford PCM still uses MAF while running at 3/4 or more throttle to update BARO. However, when the engine is at KOEO, the BARO will be changed to suit the MAP sensor in the ESM.

4.6 V8

On a 4.6L Ford engine, the EGR is a plenum dump-type EGR. See Figure 2. The fault code retrieved is for “EGR inefficient flow,” a P0401. Obviously, the thing to do next is inspect the DPFE voltage and to flow test the EGR ports.

All of this can be done in one handy test. Use your scan tool to bring up the DPFE PID (you can also use a volt meter on the DPFE signal lead). Next, select the EVR in your scanner’s bidirectional controls menu and open the EGR to 100% (if you are not using a scan tool, ground the EVR solenoid). Watch the DPFE volts and listen to the engine. In one step, we are testing the EVR, EGR, vacuum to and from EVR, DPFE sensor and the orifice inside the EGR supply tube. What happens will determine where to go from there.

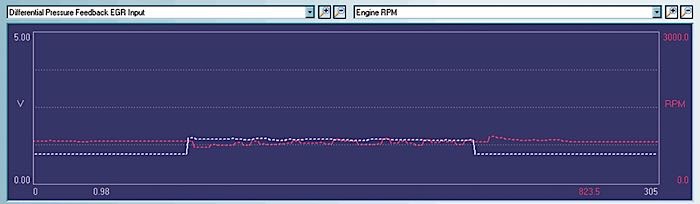

In this case, the EGR valve did open up, and some flow was detected by the DPFE. The engine ever so slightly stumbled. See Figure 2. Notice the DPFE volts and the minor fluctuation in the engine RPM on the data capture. This points to a restricted EGR.

If no change in DPFE or engine RPMs was found, then either the EGR is completely stopped up or the EGR valve isn’t opening due to a broken line, faulty EVR or no B+ to EVR. If the engine stalled or stumbled heavily but there was no change in DPFE, then it is possible the DPFE is faulty or the orifice in the EGR supply tube is missing. The presence of the orifice can be testedby using a vacuum gauge on the upstream DPFE hose with the EGR wide open. Normally, that hose will have a measurable vacuum around 5 to 10 inHg on a free-flowing EGR and good orifice in the tube. Whether you are using a scan tool or not for this testing, don’t forget to consider the PCM’s ability to open the EVR and read the DPFE in your test results.

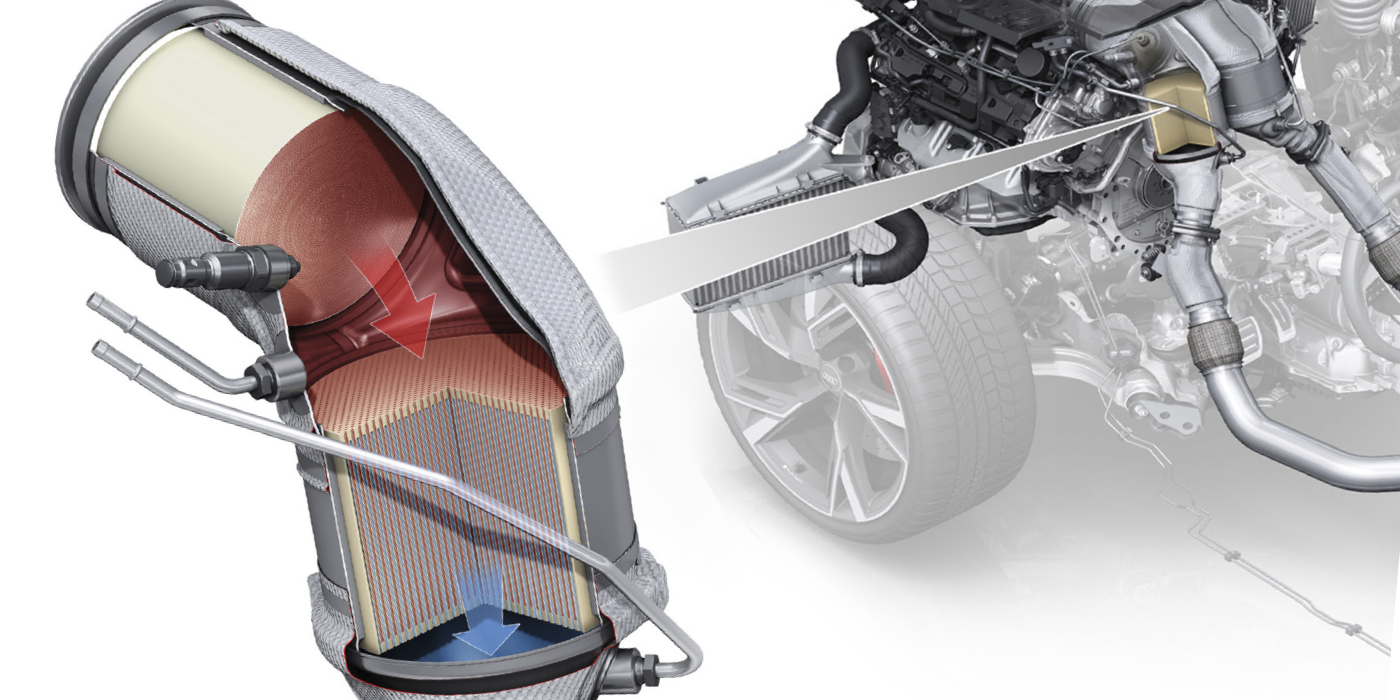

In Figure 3, the vehicle’s throttle body was removed and the EGR ports were cleaned out.

After that, the EGR system was retested in the same manner as before. Notice the DPFE readings of a clean EGR system and the disruption it caused in the engine’s running.

2.5 V6

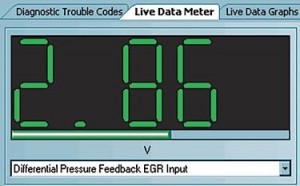

The next vehicle to consider is a Ford Contour with a 2.5L engine. The fault code is a P0401. The DPFE sensor is stuck at 2.86V (see Figure 4), so the test has to be modified a little. The EGR valve is commanded 100% as with the last example. Flow testing is done by installing a vacuum hose in the upstream hose and listening to the engine. No change in engine running quality is detected and the vacuum gauge barely twitches on the zero mark. The vacuum hose is then removed from the EGR valve to listen for the valve to slam shut with an audible “slap.” The “slap” of the EGR valve is heard, proving that it did open. Of course, this points to a restricted EGR.

The throttle body is removed for cleaning and is found to be completely stopped up. See Figure 5. The passages are cleaned. See Figure 6. The system is tested after all repairs. The 3.8L and its big brother, the 4.2L, use individual EGR ports in the lower intake to distribute the EGR to each cylinder. This poses a new issue as with another example, an E-250 van with a 4.2L engine. The complaint was a check engine Light on and engine misfire. The fault codes retrieved were P0401 and P0303 (cylinder #3 misfire). When lightly loading the engine in the bay, the engine began skipping heavily. Using the scan tool to command the EGR to close, the engine stopped misfiring with the EGR valve closed (a non-scan tool method would be to unplug either the EGR valve or EVR). Maximizing the flow in the EGR ports revealed only a peak DPFE voltage of 1.5 volts. The upper plenum was removed for cleaning.

The throttle body is removed for cleaning and is found to be completely stopped up. See Figure 5. The passages are cleaned. See Figure 6. The system is tested after all repairs. The 3.8L and its big brother, the 4.2L, use individual EGR ports in the lower intake to distribute the EGR to each cylinder. This poses a new issue as with another example, an E-250 van with a 4.2L engine. The complaint was a check engine Light on and engine misfire. The fault codes retrieved were P0401 and P0303 (cylinder #3 misfire). When lightly loading the engine in the bay, the engine began skipping heavily. Using the scan tool to command the EGR to close, the engine stopped misfiring with the EGR valve closed (a non-scan tool method would be to unplug either the EGR valve or EVR). Maximizing the flow in the EGR ports revealed only a peak DPFE voltage of 1.5 volts. The upper plenum was removed for cleaning.

All of the EGR ports were restricted except for #3 cylinder. See Figure 7. That caused the #3 cylinder to become overwhelmed with extra EGR gases. With that cylinder overwhelmed, it would misfire on that cylinder.