CC:

When ordering complete front struts for the Tundra, make sure you check if the truck is four wheel drive or two wheel drive. Also, check if the truck has the TRD package.

Lift the vehicle and remove the front wheels. Disconnect the stabilizer bar length on both lower control arms. There are two bolts that secure the ball joint to the knuckle. You can remove the outer tie rod from the knuckle to create extra clearance, but we found we didn’t need to do this. Next, remove the bolt that secures the strut to the lower control arm. Working inside the wheel well, unfasten the four nuts that hold the upper strut mount to the frame. Loosen but do not remove the bolts that secure the lower control arm to the frame. This will make the lower control arm easier to lower. Pull down on the lower control arm to remove the strut assembly.

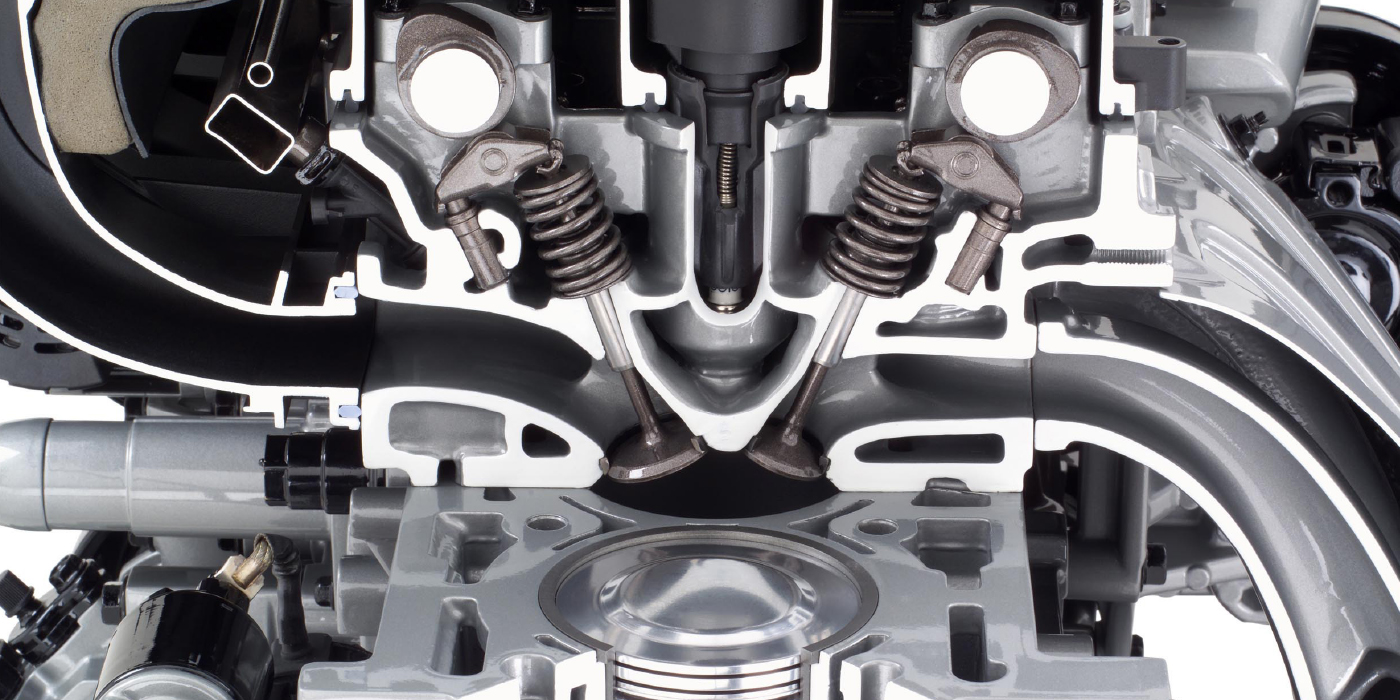

The PRT replacement is a complete assembly. The coil spring uses high quality carbon steel that matches the OE unit for the application and options. The strut unit has a precision piston rod that is chromed to ensure proper seal lubrication and resistance to impacts and corrosion, and the valving inside matches the original unit. The unit also includes new bellows and bump stops, along with a new upper strut mount and installation hardware. Move the shock into position, making sure the arrow on top of the strut mount is pointing out. Loosely install the upper four nuts. Swing the lower control arm upward, then insert the lower strut bolt. Leave this bolt loose for now. We’ll tighten it later on. Now tighten the upper nuts to 33 foot pounds. Attach the lower ball joint bracket to the knuckle. Tighten the bolts to 221 foot pounds.

Repeat this process on the other side of the truck. Then install the front wheels. Install the bolts which secure the sway bar and links the lower control arms and torque them to 89 foot pounds. Torque the lower strut bolt and nut to 144 foot pounds. Perform an alignment. Once the camera and caster has been adjusted to factory specifications, torque the lower control arm bolts to 207 foot pounds, and lower the truck to its normal ride height.

PRT or performance ride technology shares its heritage with one of the largest manufacturers of shocks, struts, and complete strut assemblies in the world. PRT products are produced and tested under the strictest OE Quality processes required by leading automakers in five modern and fully automated plants, using the latest technology available.

With nearly 30 years of expertise in ride control and suspension product manufacturing, conducting business in more than 135 countries worldwide, with a strong presence in OE and OES Developments, PRT is a leading presence in the global aftermarket business. Quality, complete coverage, advanced features and built in profit potential for customers are synonymous with PRT. Performance ride technology is in our DNA.