The typical life expectancy for most water pumps and timing belts is about 100,000 miles. That means both parts tend to go bad around the same time. If a customer comes in with a failed water pump or timing belt, it’s worth talking to them about replacing both parts at the same time even if the other part still works. Here are three main reasons to replace the parts simultaneously:

Save Hours Of Labor

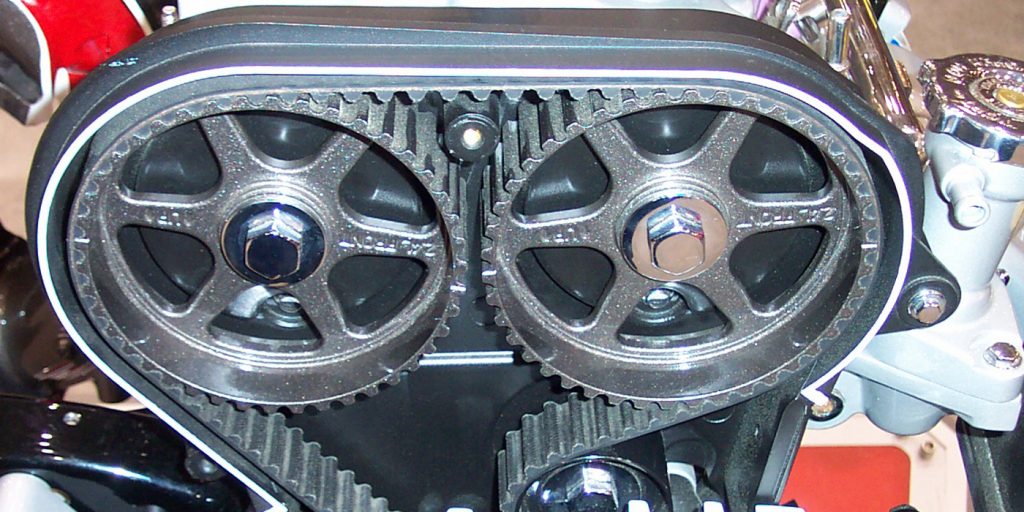

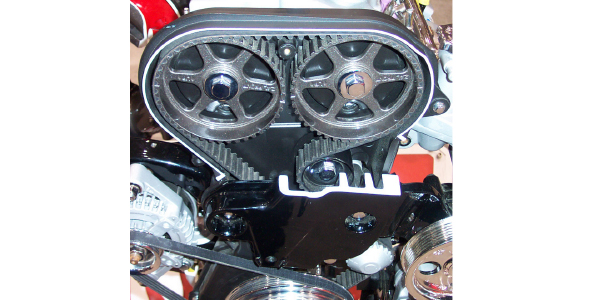

To replace either a water pump or timing belt, the engine has to essentially be taken apart, which can be tedious and is extremely time-consuming. Depending on the engine, the project can take between a few hours and a full day. Replacing both the timing belt and water pump at the same time can save half a day or more of future labor.

It’s Cheaper And More Convenient

If only one part is replaced, the customer will eventually have to bring their car back to replace the other part. Instead of being without a car again during the second repair and paying for the same labor again, the customer saves hundreds of dollars and the hassle of being without a vehicle.

It Prevents Further Engine Issues

It’s a good idea to replace the timing belt or the water pump before it actually fails because a bunch of additional engine issues can crop up when failure of either part goes undetected for too long.

When a timing belt breaks, this affects almost every part in the engine, including the valves, cylinder head, camshaft, pistons and cylinder walls. This means a broken timing belt can result in thousands of dollars of addtional and unexpected engine repairs.

When a water pump breaks, the engine can overheat. This causes problems such as warped cylinder heads, a warped engine block and even catastrophic engine failure.

Bottom line: it’s worth talking to your customers about replacing both the timing belt and the water pump at the same time.

Courtesy of GMB North America