In the past decade, turbochargers were installed on more cars and trucks than ever before. These are the top OEM and aftermarket tips to help you install a new turbocharger without a comeback.

In the past decade, turbochargers were installed on more cars and trucks than ever before. These are the top OEM and aftermarket tips to help you install a new turbocharger without a comeback.

Subaru: Turbocharger Oil Supply Line Mesh Screen Check

Turbocharged engines require proper maintenance — especially when the vehicle is used under severe driving conditions such as moderate-to-hard acceleration and engine braking on a somewhat regular basis.

In addition to regular oil changes, the mesh screen which is located inside the banjo bolt that secures the turbocharger oil supply pipe to the back of the right-side cylinder head should be checked to make sure it’s not clogged or restricted, especially if the condition of the oil is questionable. If it’s clogged or restricted, it will reduce or cut off the oil supply to the turbo, resulting in failure. The oil supply pipe should also be checked to make sure that there are no obstructions.

Note: The mesh screen is available only with a replacement banjo bolt.

Make sure the mesh screen is installed in the proper direction; incorrect installation will cut off oil supply to the turbo.

Do not confuse the oil supply mesh screen with the Active Valve Control System (AVCS) union screw filter. Refer to Service Bulletin 02-97-05 dated 10/06/05.

When the vehicle is used under severe driving conditions, the engine oil is consumed more quickly than under normal driving conditions due to high intake manifold vacuum during engine braking and higher temperatures; the engine oil level should be checked at every fuel fill-up.

Courtesy of Subaru

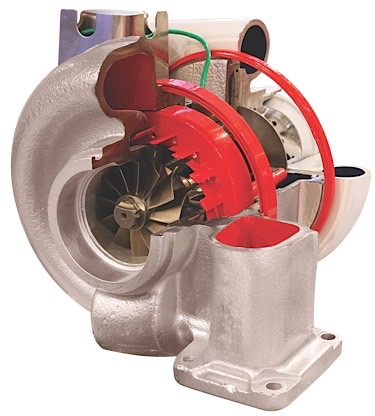

CARDONE: Preventing New Turbocharger Failures

Ninety percent of all turbocharger failures are caused by preventable problems or adverse operating conditions. Because of the close tolerances and clearances of these units, and the high speeds at which they operate, it is imperative that they are installed correctly and maintained properly.

Proper Installation:

• Some turbo installations are a metal-to-metal fit requiring no mounting gaskets; therefore, no additional gasket material should be used. The use of any RTV or similar gasket material will void unit warranty. At 100,000-plus RPM, even a small amount of loose sealant will destroy the compressor wheel. If manifold surfaces are damaged, repair or replace as necessary.

• Clean all connecting hardware and fittings. Inspect and replace pipes, hoses or ducting as needed.

• Check for adequate oil supply (functioning oil pressure/filter system). Oil supply lines must be checked. Flexible lines can degrade from the inside-out, causing pieces to be flushed down to the new turbo and clogging the oil-feed ports. Hard lines should never be bent, as this causes the material from the inside of the pipe to loosen and be flushed down the pipe upon start-up, clogging the ports.

• Check filter elements and screens. Some systems have filter screens in the oil supply line. Unfortunately, they may not have a bypass feature. If the line is blocked, the turbo will be starved of oil and quickly fail.

Systems designed this way must be checked periodically.

Courtesy of CARDONE.

BMW: Restricted Oil Supply Kills New Turbocharger

Models: All turbocharged engines

Situation: The customer complains of loss of performance and turbocharger noise.

Cause: The turbocharger oil supply may be restricted, causing oil starvation and resulting in the seizure of the turbocharger assembly.

Procedure: Upon replacement of the turbocharger assembly, always clean the surrounding area where the engine oil supply and return lines enter the engine crankcase.

• Ensure that no debris enters the engine oil supply or return galley. Contamination of the engine oil supply or return can result in additional damage to the engine.

Always remove and inspect the engine oil supply and return lines for blockage or restriction.

• Ensure that the engine oil supply and return lines are not collapsed or kinked. Replace the lines and banjo bolts (if applicable) if a blockage or restriction is detected.

• Inspection of the engine oil supply and return lines will help avoid repeated failure of the turbocharger assembly.

• Before installing a new turbocharger, pour a small amount of engine oil into the turbocharger oil supply hole to provide lubrication during the first start-up.

If the diesel particulate filter (DPF) is contaminated with engine oil due to a failed turbocharger, a diesel particulate regeneration should be performed after the new turbocharger is installed.

The DPF regeneration procedure can be found in ISTA/D Service Functions.

Courtesy of BMW

Chevrolet: Check the ECM Calibration on the Cruze to Keep the Turbocharger Cool

Models: All Cruze models with the turbocharged 1.4L engine.

This TSB advises technicians to check the ECM to make sure it’s running the latest calibration. The latest calibration contains a function that allows the cooling fans to run for a short period of time when the vehicle is off (after the vehicle has been driven under certain conditions).

This latest calibration also allows the turbocharger to cool in less time, reducing the likelihood of the oil coking in the oil feed pipe. Good vehicle maintenance practices will also help to reduce the chances of the oil coking in the oil feed pipe. To avoid the customer coming back with a concern, you should inform them of the calibration change that allows the fans to run after the vehicle is shut off.

Courtesy of GM

Chrysler: Diagnosing Dust

Models: Cummings Diesel from 2003-’12

In TSB 09-004-11, Chrysler looks at the dust in the intake and turbo system to see what can happen to the turbo system if the filter fails or non-approved intakes are installed by the customer. This nine-page TSB is a must read during some downtime. It will make some drivers think twice about skipping maintenance service or installing a performance filter.

Courtesy of Chrysler