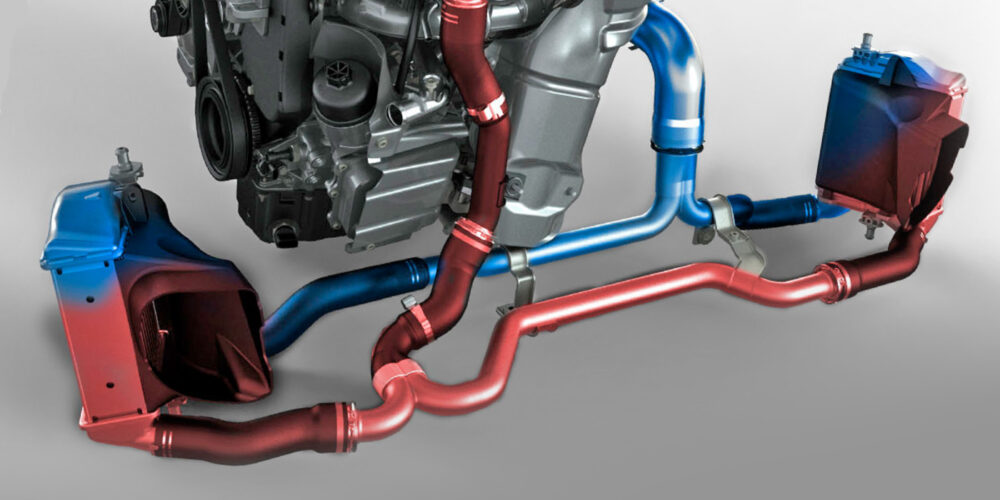

The quickest way to solve electric fan-related, engine-overheating issues is to replace the entire cooling fan assembly as a unit instead of trying to repair or replace the individual fan motor. You’ll eliminate unnecessary steps, hassles and unbillable labor.

The quickest way to solve electric fan-related, engine-overheating issues is to replace the entire cooling fan assembly as a unit instead of trying to repair or replace the individual fan motor. You’ll eliminate unnecessary steps, hassles and unbillable labor.

Fan motor replacements can take almost twice as much time. You have to pull the assembly, remove the blade and replace the fan motor, and then refit the fan assembly. Some assemblies use rivets that need to be drilled out and some use special fasteners, which cannot be reused.

The biggest hassle is the plastic shroud, which after years of use and exposure to temperatures may be too brittle to handle the refit.

You can avoid guesswork and installation hassles with VDO Cooling Fan Assemblies. Made to OE specs for vehicle-specific fit, form, function, and proper cooling airflow, they come ready to install with an exact OE fit connector and shroud. Most importantly, VDO Fan Assemblies feature an OE-style motor, which delivers long-term reliability and service life.

For more info: vdo.com/usa or contact: [email protected].