Gasoline can contain many impurities and pick up contaminates on the long journey from the refinery to the corner station. Once it is delivered, it may sit for weeks in old underground storage tanks. For customers who want to make sure the fuel reaching their engines is as pure as possible, recommend new super-concentrated Gas Treatment from Rislone.

Gasoline can contain many impurities and pick up contaminates on the long journey from the refinery to the corner station. Once it is delivered, it may sit for weeks in old underground storage tanks. For customers who want to make sure the fuel reaching their engines is as pure as possible, recommend new super-concentrated Gas Treatment from Rislone.

Rislone Gas Treatment conditions fuel to prevent gum and varnish buildup. It helps gasoline burn cleanly, which improves performance and extends engine life. One super-concentrated six-oz. bottle should be used with every fill-up to maintain optimum efficiency.

“Over time, particles in untreated gas can build up and rob an engine of its power,” says Clay Parks, Rislone vice president of development. “Preventive measures like the regular use of Rislone Gas Treatment can save drivers from expensive repair bills down the road. We made the product as convenient as possible by concentrating all the ingredients into a small, single-use bottle.”

Gas Treatment (P/N 4777) comes packaged in Rislone’s new EZ Nozzle bottle, which is built to perform better than standard additive bottles, says the company. The EZ Nozzle bottle features a built-in flow valve that prevents spills by giving users time to properly insert the bottle into the fuel filler neck. EZ Nozzle is also designed to work with capless or obstructed fuel systems. When inserted into a capless tank, the EZ Nozzle opens the fuel system safety door and allows the additive to flow in smoothly.

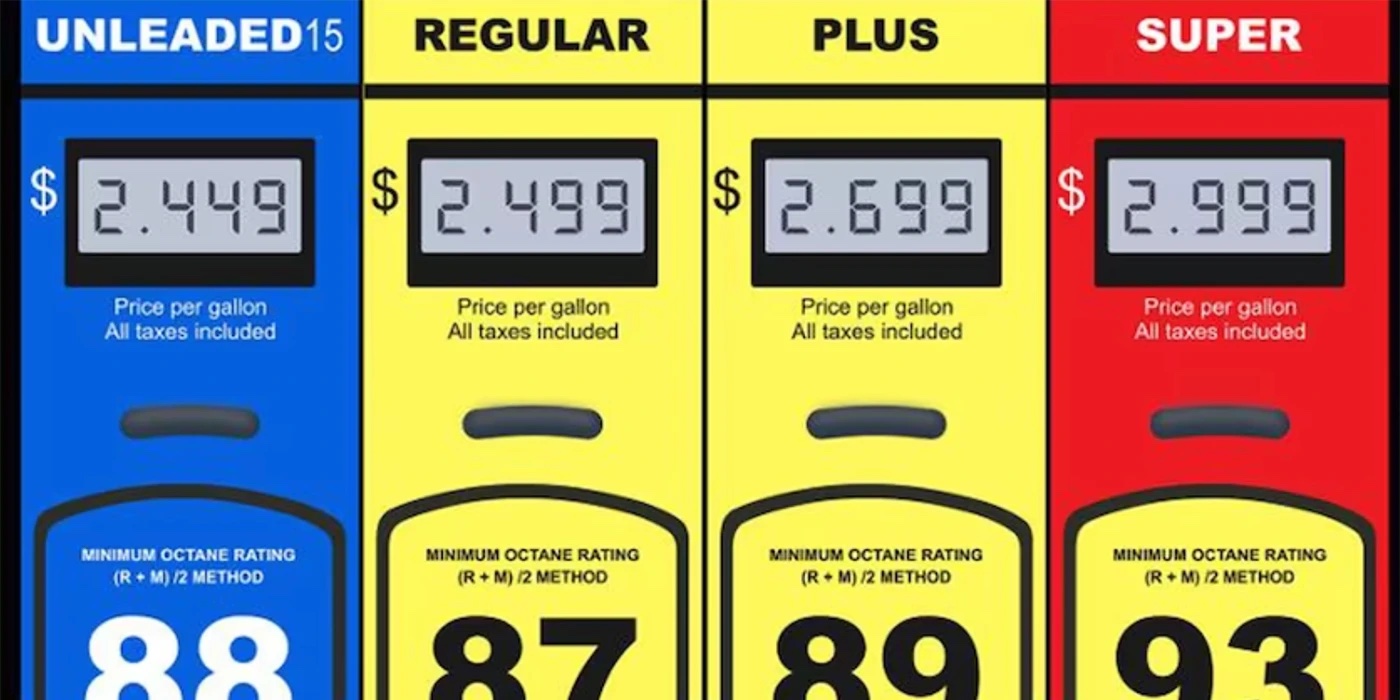

Rislone Gas Treatment works with all gasoline types, including flex fuel and ethanol blends. It is compatible with fuel-injected, turbo, direct-injected and carbureted engines.

Like all Rislone products, Gas Treatment is made in the U.S.A. It is available to distributors in PDQ display case packs of 12.

For more information about the full line of Rislone premium performance chemicals, visit www.rislone.com, email [email protected] or call (800) 521-7475. You can also follow Rislone on Facebook at www.facebook.com/Rislone, on YouTube at www.youtube.com/barsproducts and through the blog at www.barsproducts.com/blog.