Non-Transmission Sensors Causing Transmission Problems

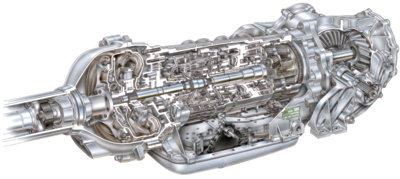

Most transmission control modules use inputs from other sensors on the vehicle. If a vehicle can’t accurately calculate the load on the engine, it will adjust the line pressure and slippage to the inaccurate calculation. This can damage the transmission.

Sensors used to calculate the load can include the Mass Airflow Sensor (MAF), Throttle Position Sensor (TPS) and Manifold Air Pressure (MAP). If unmetered air is entering the cylinder through a leak, the engine load will be below the actual percentage. This can cause the module to use different shift points and line pressures. This could cause the transmission to delay shifts, overheat and possibly burn the fluid.

Maintenance items like a restrictive air filter, dirty air flow meter or blocked crank case ventilation system can change the calculated engine load to the point where it can influence shift points and shift quality.

Wiring Harness Problems

The wiring harness and connectors on most transmissions operate in a unique environment. Normal automatic transmission fluid’s conductivity is very low. Hybrids usually have a specification for a fluid that is non-conductive. In most cases, the fluid will not damage or short the connections; the detergents and chemicals will cause the degradation of the materials in the wiring harness that might be outside of the case.

Also, check for any damaged wires and connections that could be damaged by impact with road debris, weak or shifting motor mounts and hot exhaust systems.

Grounds

Since the mid 1990s, the grounds for solenoids and sensors have changed dramatically. Never assume the chassis ground is coming through the case or valve body. Study the wiring diagrams before trying to diagnose a dead or open solenoid. Some transmissions can have multiple ground points for the solenoids, module and sensors.

Lifter Deactivation

The area of contact between the lifters and cam lobes is the highest loaded surface inside an engine.

The basic function of a valve lifter is pretty simple. It sits on the camshaft and transfers the motions of the cam lobe up through the pushrods and rockers to open and close the valves. The size and shape of the cam lobe under the lifter (multiplied by the ratio of the rocker arms) determine valve lift and duration. As such, the lifter just follows the motions of the cam. But, it does play a role in valvetrain lash (clearance) and noise.

Alternator Testing For No Charge Conditions

Many alternator problems turn out to be nothing more than a bad connection at the alternator or a bad wiring harness.

Understanding Coolants

All-season coolant used inorganic acid technology and worked great for almost 30 years.

Ignition System Do’s and Don’ts

Why do ignition systems give technicians problems when diagnosing ignition-related misfires? The answer is that some technicians use tests that might give inconclusive results or do damage to the coil or drivers inside a module.

Tools To Service Serpentine Belts

Servicing the serpentine belt on some vehicles is a tough task.

Other Posts

Battery Charging and Diagnostics

Here are six tips to use when diagnosing a vehicle with a dead battery.

Why Do Timing Chains Stretch?

As the timing chain wears, it can change the timing of the camshaft and crankshaft.

Carbon Deposits and Direct Injection Engines

The primary cause of these problems is that fuel and added detergents are not hitting the back of the intake valves.

Hyundai & Kia Hybrid Drivetrain

The Hyundai hybrid system has a motor control unit (MCU) and hybrid control unit (HCU).