An Infiniti driver may complain of a screeching noise when the vehicle is first started in the morning. The noise dissipates once the vehicle is warmed up. This condition may occur if the water pump had recently been replaced and the fan coupling to water pump flange bolts were not torqued correctly.

An Infiniti driver may complain of a screeching noise when the vehicle is first started in the morning. The noise dissipates once the vehicle is warmed up. This condition may occur if the water pump had recently been replaced and the fan coupling to water pump flange bolts were not torqued correctly.

The fan mounting flange of the water pump may become loose on the shaft if the fan, fan coupling or water pump pulley (fan pulley) are not properly installed during a repair. The result may be a screeching noise from the engine when starting cold. When removing or installing the fan, fan coupling or water pump pulley always perform the repair procedure.

Applicable Vehicles

All 1997 models with a water pump-mounted fan.

Repair Procedure

1. Turn the ignition switch to “off.”

2. Loosen the alternator then remove the drive belt. Do not leave the belt in place and release the drive belt tension by removing the water pump pulley. (Releasing the drive belt tension by removing the water pump pulley may complicate component re-installation).

3. Remove the fan, fan coupling, water pump pulley and any other components required for the service you are performing.

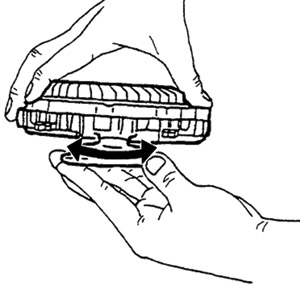

4. Inspect the fan coupling for wobbling (Figure 1), oil leakage or bent/broken bimetal before assembly.

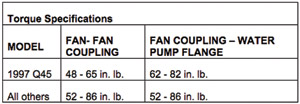

5. Carefully install the fan, fan coupling and water pump pulley. Torque the M6 x 0.8 nuts and screws securing the fan to the fan coupling and the fan coupling to the water pump flange according to the table above. Install the drive belt only after the fan and fan coupling to water pump flange bolts/nuts have been properly torqued.

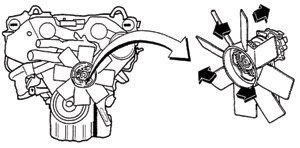

Note: Proper alignment of these components is essential. See Figure 2. Improper alignment will cause them to wobble and may eventually cause the fan to separate from the water pump causing extensive damage.

Note: Proper alignment of these components is essential. See Figure 2. Improper alignment will cause them to wobble and may eventually cause the fan to separate from the water pump causing extensive damage.

6. After assembly, verify the fan does not exhibit any wobble or flapping while the engine is running. If any wobble or flapping is observed, it must be corrected before the vehicle is released to the customer.

Caution: When the engine is running, keep hands, clothing and jewelry away from moving parts such as drive belts and fan.

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience. Courtesy of ALLDATA.