By Rich Diegle

Senior Automotive Editor

If a 2003 or 2004 Nissan Murano owner comes into your shop concerned about popping noises when turning the steering wheel, and/or the steering wheel alignment keeps changing, the problem may be loose steering rack mount bolts. Follow the Repair Procedure to properly tighten the bolts.

Repair Procedure:

Review safety procedures in ALLDATA Repair before beginning.

Applicable VINS:

2003 Murano – all VIN’s

2004 Murano – built up to JN8AZ08 T (*)4W 203356, or JN8AZ08 W (*)4W 305397

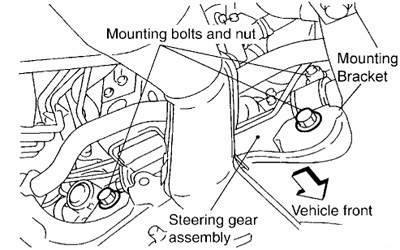

1. From under the vehicle: check the torque on the two steering rack mounting bolts and one nut (Figure 1).

Bolt Torque: 101-119 Ft-lb. (136-162 N.m, 14-16 Kg-m).

Nut Torque: 90-109 Ft-lb. (121.6-149.1 N.m, 13-15 Kg-m).

2. Remove the steering gear (rack) mounting bolts and nut.

2. Remove the steering gear (rack) mounting bolts and nut.

3. Clean any loose or excess paint or other debris that may be on the bolts, threaded bolt holes, and/or mounting bracket surfaces.

NOTE: Check both sides of each mounting bracket. Push up on the steering rack so you can see all of the mounting surfaces.

4. If you chip off any welding slag or scrape off paint globs from the steering rack mount bracket, spray (apply) black paint on any "bare metal" areas.

NOTE: Use a local source for black spray paint.

5. Reinstall the bolts and nut.

Re-torque the mounting bolts to the upper end of the specification.

Bolt Torque: 115-119 Ft-lb. (155-162 N.m, 15.8-16 Kg-m).

Re-torque the mounting nut to specification.

Nut Torque: 90-109 Ft-lb. (121.6-149.1 N.m, 13-15 Kg-m).

6. Perform front wheel toe adjustment.

NOTE: At the start of the toe adjustment, first make sure the steering wheel is centered.

Written by ALLDATA Senior Automotive Editor, Rich Diegle. Rich is an Advanced Engine Performance Certified, ASE Master Technician with an AA Degree in automotive technology and 23 years of dealership and independent shop experience.

For additional information, visit www.alldata.com.