On E38 750iL models with the M73 engine, a whining noise that is generated by the rotation of the timing chain at approximately 1,000 – 1,500 rpm may be heard at all engine temperatures.

The timing chain noise is a normal engine operating noise that is transmitted to the body of the vehicle and into the passenger compartment via the engine, transmission and exhaust system mounts.

To reduce the amount of transmitted timing chain noise, new mounts and engine mount vibration dampers were developed for 750iL models with M73 engines produced up to August 1999. The new mounts were phased into production in September 1999.

Replace the engine mounts, transmission mounts and center exhaust mounts to correct the problem.

Service Procedure: 1. Remove the lower engine splash guard.

1. Remove the lower engine splash guard.

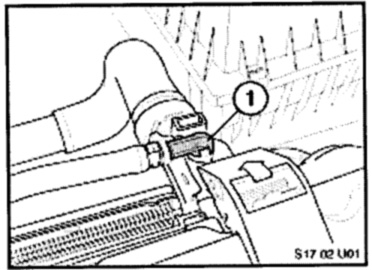

2. Loosen both the left- and right-side engine mount nuts. See Fig. 1 (right side is shown in figure).

3. Remove the exhaust system. (See repair manual, group 18, section 1800 020.)

4. Replace the center exhaust mounts with new mounts, P/N 18 21 1 745 426.

5. Replace the engine mounts with new mounts, P/N 22 111 092 824 (right side) and 2 111 092 823 (left side).

- Remove the upper section of both air filter housings and the center plastic engine cover.

- Remove the radiator fan (see repair manual, group 11, section 11 52 020) and the two lower nuts on each engine mount.

- Carefully raise the front of the engine approximately 1 inch (25 mm) for appropriate clearance to remove and install the mounts.

6. Install new engine mount vibration dampers, P/N 22 11 6 750 246, on top of the new engine mounts. Tightening torque: 31 ft.-lb. (42 Nm).

Note: The new engine mount vibration dampers replace the original engine mount holddown nuts.

7. Reinstall the upper sections of both air filter housings and the center plastic engine cover.

8. Reinstall the radiator fan (see repair manual, group 11, section 11 52 020). Tightening torque: 29.5 ft.-lb. (40 Nm).

9. Support the rear of the transmission and replace the rear transmission mounts with new mounts, P/N 24 70 1141 545.

10. Reinstall the exhaust system. See repair manual, group 18, section 18 00 020.

11. Reinstall the lower engine splash guard.

Technical service bulletin courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.