A repair kit is available that eliminates oil leaks coming from the control valve cover area of the oil filter housing on all M20 (B25 with engine oil cooler) and S14 (M-Power) engines.

A repair kit is available that eliminates oil leaks coming from the control valve cover area of the oil filter housing on all M20 (B25 with engine oil cooler) and S14 (M-Power) engines.

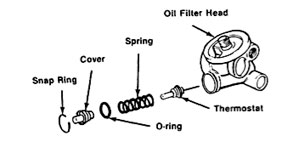

An O-ring with improved material quality (Viton) has been developed by BMW. The new repair kit (consisting of 1 Viton O-ring, 1 cover and 1 snap ring) must be installed whenever an oil leak is detected coming from the control valve cover of the oil filter housing (see illustration). This repair kit will eliminate the need to replace the complete oil filter housing and can be installed without removing the oil filter housing from the engine.

Repair Procedure:

• Clean oil filter head cover area;

• Clamp the control valve cover using a 4-inch "C" clamp and lift snap ring out of its seat using a small bladed screwdriver or similar tool;

• Carefully remove the control valve with the O-ring. Catch escaping engine oil. Caution: The cover spring is loaded;

• Replace the O-ring, cover and snap ring included in the repair kit. Note: On S14 engines (M3 vehicles), only the O-ring and snap ring should be replaced since the control valve cover differs in design from the M20 engines.

• Run the engine to operating temperature (80° C oil temperature) and check control valve cover area for leaks; and

• Check engine oil level and top off if necessary.

The repair kit can be ordered under BMW part number 11 42 9 059 338.

Some or all of this information was provided by the Automotive Parts Remanufacturers Association (APRA). For more information on technical bulletins available through APRA call (703) 968-2772 or visit www.AutoBulletins.com.