Rotary Lift (www.rotarylift.com) has redesigned its SmartLift inground lift’s standard two-stage arms to enable them to reach manufacturer-recommended pick-up points on a much wider range of vehicles, from low-profile sports cars to full-size light trucks.

Rotary Lift (www.rotarylift.com) has redesigned its SmartLift inground lift’s standard two-stage arms to enable them to reach manufacturer-recommended pick-up points on a much wider range of vehicles, from low-profile sports cars to full-size light trucks.

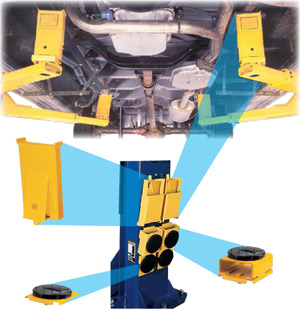

Rotary is the first U.S. lift maker to offer side-mounted two-stage arms on an inground lift. This positioning enables the inner arm to slide back through the outer arm tube to provide a minimum arm reach that is 2-1/2 inches shorter than old two-stage front arms. SmartLift’s new front and rear two-stage arms can retract to 19-5/8 inches and extend to 42-3/8 inches, providing a much greater arm sweep and reach.

Two-stage arms are standard on SmartLift inground lifts (models SL210 and SL210i). In recent years, customers who regularly needed to pick up vehicles with wide vehicle track width, low profile, short wheelbase or long wheelbase would select a SmartLift equipped with three-stage arms because the arms’ greater extension and retraction enabled them to access hard-to-reach pick-up points. The SmartLift’s new two-stage arms give many of those customers another option. Additionally, Rotary has recessed the SmartLift’s mounting bolts, increasing drive-over clearance by 5/8 inch to reduce concerns about scraping the undersides of low-profile vehicles.

“Our new two-stage arms retract as far as our competitors’ three-stage arms and extend even farther,” says Jason Matthews, Rotary Lift advance design engineer. “So technicians using a SmartLift can properly lift more vehicles, for greater productivity.”

The best retraction is still provided by Rotary Lift’s three-stage arms, which have a minimum arm reach of 18-3/8 inches. These arms offer a lower adapter height, as well, which is helpful when picking up low-profile vehicles.

No matter what the arm configuration, all Rotary SmartLift inground lifts include many environmentally friendly features. The lifts are entirely self-contained in a polymer composite housing made from recycled materials. This containment unit protects the environment from any potential leaks, while at the same time protecting the lift from the environment. A SmartLift uses less than five gallons of hydraulic fluid, compared to the 95 gallons required by old-fashioned inground lifts.

SmartLift inground lifts have a smaller footprint than two-post surface lifts, so 12 SmartLifts can fit in the same space as 11 surface lifts. The SL210i includes a patented LDS liquid detection system to alert the technician if moisture develops in the lift housing. A liquid removal system is available.

Like all SmartLifts, the SL210/SL210i models use Easy Access cylinders and hydraulic hoses that can be serviced without removing the lift from the ground, reducing service call times and related downtime up to 75 percent over competitive models.

The SL210/SL210i SmartLifts are ETL/ALI certified. Lifting capacity is 10,000 lbs.

For more information about the Rotary Lift SL210/SL210i SmartLift inground lift, or any other Rotary Lift products or services, contact your local Rotary distributor, call Rotary at (800) 640-5438 or visit www.rotarylift.com.