Visit any online forum dedicated to the Jeep® Wrangler JK, and you’re likely to find threads focused on solutions for fixing a worn or damaged ball joint. That’s because ambitious off-roading, popular modifications, and the design of the original equipment part can all contribute to ball joint failure in the Jeep JK. Ball joints are essential to proper steering capabilities, and total part failure can have disastrous results, so many enthusiasts on JK forums—and the pros—recommend upgrading to a heavy-duty ball joint. An upgraded ball joint will also help prevent premature part wear and ensure that wheel alignment stays true in a Jeep JK.

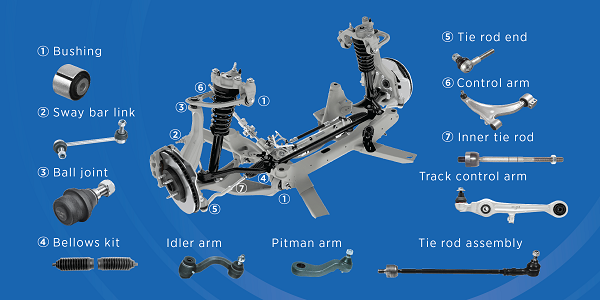

Ball joints link the steering knuckles to the control arms, allowing the vehicle’s wheels to move in synch with the suspension system when a driver turns the steering wheel. Since they support tight, reliable control of the suspension system, steering that feels loose or wobbly may indicate ball joint wear. Mysterious clunking noises and uneven tire wear may also expose the need for part replacement. Ball joints should be examined as soon as wear is suspected.

When any of these symptoms appear, JK owners may wonder what leads to ball joint wear in these generally reliable rigs. The short answer is that the original equipment (OE) ball joints are adequate for standard, everyday driving, but they don’t stand up as well to more extreme stresses. The OE design includes a plastic liner that is susceptible to wear and corrosion. In addition, if water, dirt, or other debris contaminate the OE ball joint’s lubrication, it can’t be serviced and purged with additional grease. When you factor in the rough trails and rubble of off-roading, and the extra stress placed on vehicle joints by modifications such as installing larger-than-stock tires, premature ball joint wear seems almost inevitable.

“When Jeep owners upgrade to bigger tires and make modifications such as adding body armor, roof top tents, or new bumpers, the heavier weight adds stress to the vehicle. This added weight can shorten the life of the axle and its components,” says Bill Nunnery, senior director, sales and marketing, global aftermarket for Dana. Considering the stresses that ball joints are subjected to, it’s wise to select a higher-quality option featuring metal-to-metal construction. This offers increased resistance to deflection and deformation. Also, look for a design with a grease zerk for serviceability, so owners or techs can extend part life by purging contaminants with fresh lubricant.

For a major upgrade from the OE part, check out Spicer® Performance ball joint kits for the Jeep Wrangler JK. These ball joint kits feature everything required to service the front left or front right corner of a Jeep JK—one upper and one lower ball joint, plus nuts and cotter pins. Not only will they prevent uneven tire wear and prolong part life, but “installing a Spicer Performance ball joint kit when upgrading will reduce the chance of experiencing rapid oscillating in the steering components that results in a harsh shaking of the steering wheel,” says Nunnery.

It’s unlikely that the original part will last the lifespan of a vehicle, so choose an aftermarket ball joint kit that can be the final ball joint replacement. When owners enjoy off-roading or are upgrading to larger tires, a performance ball joint for the Jeep Wrangler JK will help maintain ideal wheel alignment and prevent untimely part deterioration. A heavy-duty ball joint upgrade will ensure that Jeep JK owners get the performance they demand from their vehicles, both on the road and on the trail.

This article was sponsored by Dana Incorporated. For more information, please visit https://www.dana.com/.