A vehicle’s steering and suspension system is integral to its ride, handling, safety, and must always be up to the job–that’s where Delphi comes in.

All Delphi chassis parts undergo rigorous dimension, material, durability, temperature, and performance tests to ensure they meet or exceed OE specifications at every turn. Because Delphi’s debut in steering and suspension began in Europe, it’s allowed us to have a more thorough understanding of foreign nameplate vehicles as well. This can be seen in our diverse portfolio for North America, where we’ve incorporated deeper technical expertise, innovation, and knowledge through sheer experience in the market.

Delphi Steering and Suspension at a Glance

In North America, Delphi’s chassis portfolio contains well over 7,000 SKUs, with many more planned for the near future. For 2023, Delphi has launched 123 SKUS, covering nearly 63 million VIO in the United States.

Here are just a few of the highlights about the part types we’ve announced in 2023.

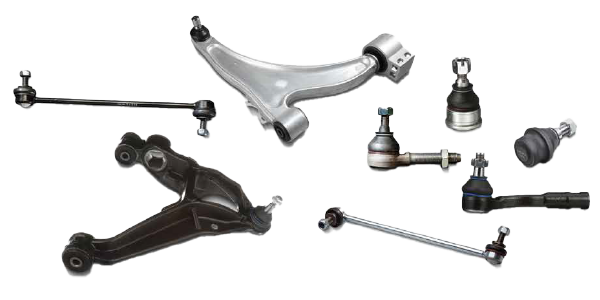

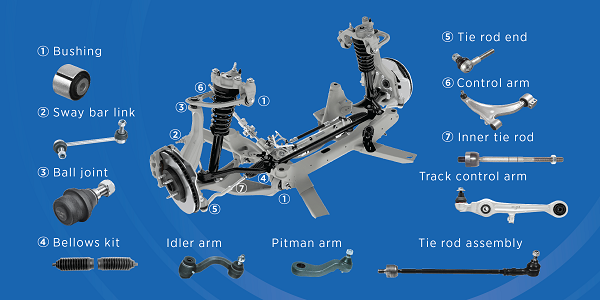

· Ball Joints

o Low-friction, high-performance thermoplastic bearing matches or exceeds OE specifications for seating and rotational torque.

o Rust-beating cataphoretic coating on housing offers premium protection against corrosion from salt, dirt, and water.

o High-grade chloroprene rubber cover keeps out contamination from dirt and moisture.

· Control Arms

o Intense flaw detection process includes ultrasonic flaw and 100% crack detection to ensure all materials meet or exceed OE specifications.

o Chloroprene rubber boot improves durability and protects against contamination.

o High specification grease for longer service intervals.

· Sway Bar Links

o Reinforced link rods make our parts strong and sturdy for a long service life.

o Application-specific hybrid composite end caps reduce weight with increased durability.

o High-precision ball pin with a smoother finish for durability, smooth joint operation, and superior angle dynamics

· Tie Rod Ends

o Low-friction, high-performance thermoplastic bearing matches or exceeds OE specifications for seating and rotational torque.

o Rust-beating cataphoretic coating on housing offers premium protection against corrosion from salt, dirt, and water.

o Tech-friendly grip points feature a hex flat at threading point for an easy grip with a standard wrench and easy repair with no extra tools required.

For more information about our steering and suspension offerings, visit our website delphiaftermarket.com.

This Article is Sponsored By: Delphi Technologies