The Toyota Scion TC is the odd one in the Toyota fleet. The TC shares its platform with the Avensis, which was not sold in the U.S., and shares some brake components with the Corolla and even the Camry. There are no brake-specific TSBs or recalls for the 2005-2010 TC.

The Toyota Scion TC is the odd one in the Toyota fleet. The TC shares its platform with the Avensis, which was not sold in the U.S., and shares some brake components with the Corolla and even the Camry. There are no brake-specific TSBs or recalls for the 2005-2010 TC.

The replacement of the pads and rotors is straightforward, but there are some things that you should know before you start.

This car is designed for ceramic friction material formulations. If everything is operating correctly, it is not uncommon for a set of rotors to last three sets of ceramic pads. Toyota even recommends not machining the rotors if the rotors are within specifications for thickness, thickness variation and runout.

The new friction materials must be compatible with the old or the rotor surface must be fresh with the right surface so a transfer layer of new friction material can be applied by the new pads.

Basics

•Lug Nuts Torque: 76 ft/lbs

• Caliper Bracket Bolts: 35 ft/lbs

• Caliper Guide Pin: 25 ft/lbs

Front Brakes

The front brakes use a vented rotor. The minimum runout specification is 0.0020”. This can be adjusted with a runout correction plate that fits between the hub flange and rotor. The plates can correct up to .006” of runout. Fine tuning can be performed with taper of the correction plate and the runout in the hub and rotor. Also, an on-the-car lathe can be used.

In most service information, you will not find a specification for disc thickness variation (DTV). But, most engineers will say that there should be zero or less than .0005”.

The OE brake pad shim is a two-piece style with the inner shim designed to move or float between the outer pad and backing plate. The shim should not be reused due to deflection and corrosion. Toyota does indicate that the inner shim can be lubricated to resolve noise.

The wear sensor is mounted on the inner pad and should be mounted on top.

Rear

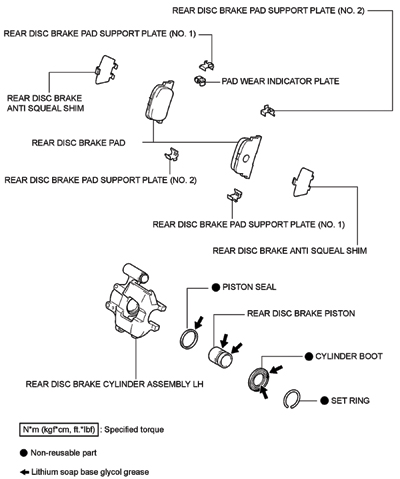

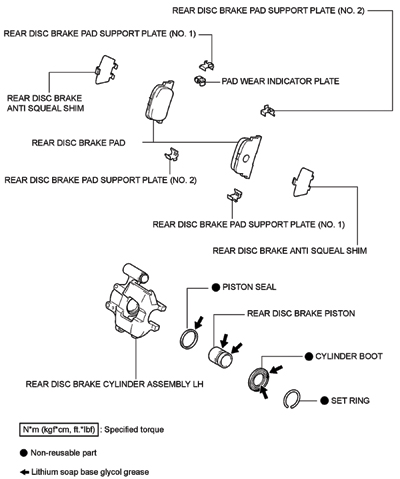

The rear brakes used solid rotors and single piston calipers, and the parking brake is mounted in the hat.

The rear runout specification is around .006”, but your goal should be around .002-.003”. Leaving too much runout may result in a pulsation problem in a few thousand miles. Runout can be corrected using runout correction plate that goes between the rotor and hub flange. On-the-car brake lathes can be used to correct runout only if there is enough material on the rotor.

The trickiest item on the rear brakes is the boots and bushings for the slide pins. Make sure the seals and lips are fully seated. Also, the pads have eight abutment clips that fit over lands on the caliper bracket.

ABS

The TC uses a four-channel ABS system. The factory scan tool or enhanced scan tool has diagnostic tests to check pump and solenoid function. The TC uses four active wheel speed sensor that generate square-wave signals. The tone rings are located in the inner seal of the wheel bearing. All the bearings are pressed into the knuckles.

Bleeding

The TC’s conventional brake system can be bled using a number of ways. The bleding sequence is RR, LR, RF and LF. The HCU can be bled using a scan tool with the right software.

Parking Brake Adjustment

1. Remove the hole plug on the backing plate, and turn the toothed adjuster to expand the shoes until the disc lock.

2. Back off the shoe adjuster until the disc can rotate smoothly.

3. Back off the adjuster another eight clicks.

4. Check that there is no brake drag.

If there is too much travel in the lever, the cable can be adjusted at the lever by removing part of the rear console. Toyota recommends six to nine clicks.

The Toyota Scion TC is the odd one in the Toyota fleet. The TC shares its platform with the Avensis, which was not sold in the U.S., and shares some brake components with the Corolla and even the Camry. There are no brake-specific TSBs or recalls for the 2005-2010 TC.

The Toyota Scion TC is the odd one in the Toyota fleet. The TC shares its platform with the Avensis, which was not sold in the U.S., and shares some brake components with the Corolla and even the Camry. There are no brake-specific TSBs or recalls for the 2005-2010 TC.