Time measures the profitability of both a shop and technician, and experience is the best tool for profitability and productivity. The more you work on cars and trucks for a living, the more realize that some things might cost you pennies, but not using it can cost you dollars—this is certainly the case with WD-40 Specialist® Penetrant with EZ-REACH®

To understand why it’s so important to use a penetrant like WD-40 Specialist Penetrant with EZ-REACH, it’s important to know just what a penetrant does. Is it magic? Not really. It’s much simpler in that penetrants and lubricants help to reduce friction, therefore breaking the bonds between the friction surfaces of the threads.

A bolt and nut use friction to hold clamping loads. The threads create surface area that is used to create this friction. The amount of friction depends on the surface area and clamping loads created by the pitch and rotation torque.

Friction Science

Think of friction as a high-performance brake system. A brake rotor and pads are like the threads. The larger the rotor or brake pads, the more friction or torque the brake system can generate. The clamping loads are determined by the hydraulic forces behind the caliper’s piston. Applied to a threaded fastener, the threads are the brake pads and rotor, the caliper is the wrench turning the threads.

So, what happens when you introduce a lubricant onto a brake rotor or pads? Friction is reduced, and stopping distances are increased. When a fastener’s threads are lubricated, friction is reduced, and the amount of torque required to break loose a fastener is reduced.

WD-40 Specialist Penetrant with EZ-REACH is a fast-acting penetrant that breaks through corrosion and rust. The penetrant has low surface tension, which generates capillary action. This means it will penetrate the tightest spaces of a fastener, even creeping upwards in defiance of gravity to reach tiny cracks and gaps to reduce friction between threaded surfaces.

Time and Money

But what do you care? You have the most powerful impacts and longest breaker bars to apply more torque. The reality is with some stuck fasteners, more torque can cost you more time. Most fasteners have a limit of torque they can withstand before they strip, stretch or break. For some fasteners, it is a fine line between breakaway torque and a broken bolt or screw.

For technicians working on flat rate, dealing with a busted fastener can put you into the unprofitable zone when it comes to hours a job will pay. Taking a little time to spray down a fastener with WD-40 Specialist Penetrant with EZ-REACH can lower the potential of damaging a fastener by decreasing the friction.

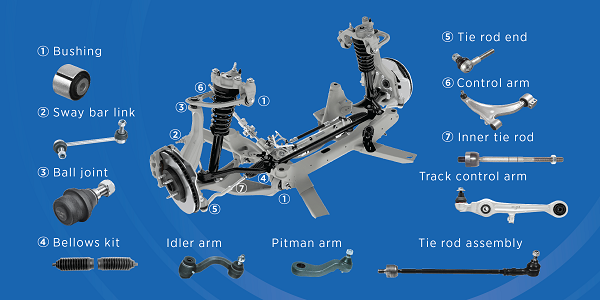

On some jobs, it might be challenging to spray a bolt or nut with WD-40® Multi-Use Product. For example, it could be an exhaust manifold shoehorned next to a strut tower or a bolt holding a wheel bearing to a knuckle. But, with the new WD-40 Specialist Penetrant with EZ-REACH, it is possible to reach challenging bolts with the flexible straw.

WD-40 Specialist Penetrant with EZ-REACH penetrates up to two times faster than the competition* and prevents rust 10x longer than the competition**. The ingredients and aerosol propellants are 50-state VOC compliant and have a lower number of lingering odors. The formulation is safe to use on plastics and rubber. It will also not damage wiring, connectors and sensors.

No matter which WD-40 Specialist product you reach for, the decades of science behind WD-40 Brand products and formulas deliver the superior performance you need to get the Job Done Right™. WD-40 Specialist Penetrant with EZ-REACH is available at Advance Auto Parts.

- Test Lab: Fred Cuneo (3rd Party); Nail Climb Test; Test date: 03/2021.

** Test Lab: WD-40 Co. Technical Center (Pine Brook, NJ); ASTM B117; Test date: 02/2021.