Another wheel bearing. You know what you’re in for, and right away you’re thinking is it going to come out easily, or is it going to be stuck in the knuckle like it was set in concrete? And what other problems are you going to run across? How bad is the rust and corrosion going to be and will you find previous damage from incorrect installation procedures?

Here’s the good news: If you’re installing a pre-assembled knuckle-hub assembly, you’ve just hit the fast forward button past all the tough parts, and you won’t have to worry about the time or how long it’s taking. You can slow down and concentrate on the most important aspects of installation, providing your customer with nothing short of undeniable quality.

When you’re installing a knuckle/hub assembly, the first thing to focus on is the attachment points. Ball joints and tie rod ends are secured by either a pinch-bolt or taper-fit type of attachment. Where there’s a pinch-bolt attachment, be sure to thoroughly clean the ball stud on the ball joint or tie rod end. Built up corrosion can affect the installation.

They should slide easily in place into the steering knuckle with no hammering and be sure to always torque any pinch bolts to the proper specification. Over-torquing can distort the hole and damage the ears on the knuckle.

When it’s a taper-fit attachment, clean the threads on any ball stud so you can install the nuts by hand. Never use an air tool, because you can easily overtighten the ball stud, which can distort and damage the taper, pull the stud too far through the knuckle and lead to a loose fit, as well as the possibility of a broken ball stud.

Next, be sure the knuckle to strut bolts are properly torqued, as well as any brake caliper bolts. Before sliding the CV joint through the new wheel hub, thoroughly clean the splines. Rust, dirt or grease will affect the torque.

Always use a new axle nut or bolt. Old fasteners can fatigue and lose their ability to maintain the proper clamping force. Now, properly tightening that axle fastener is a critical step.

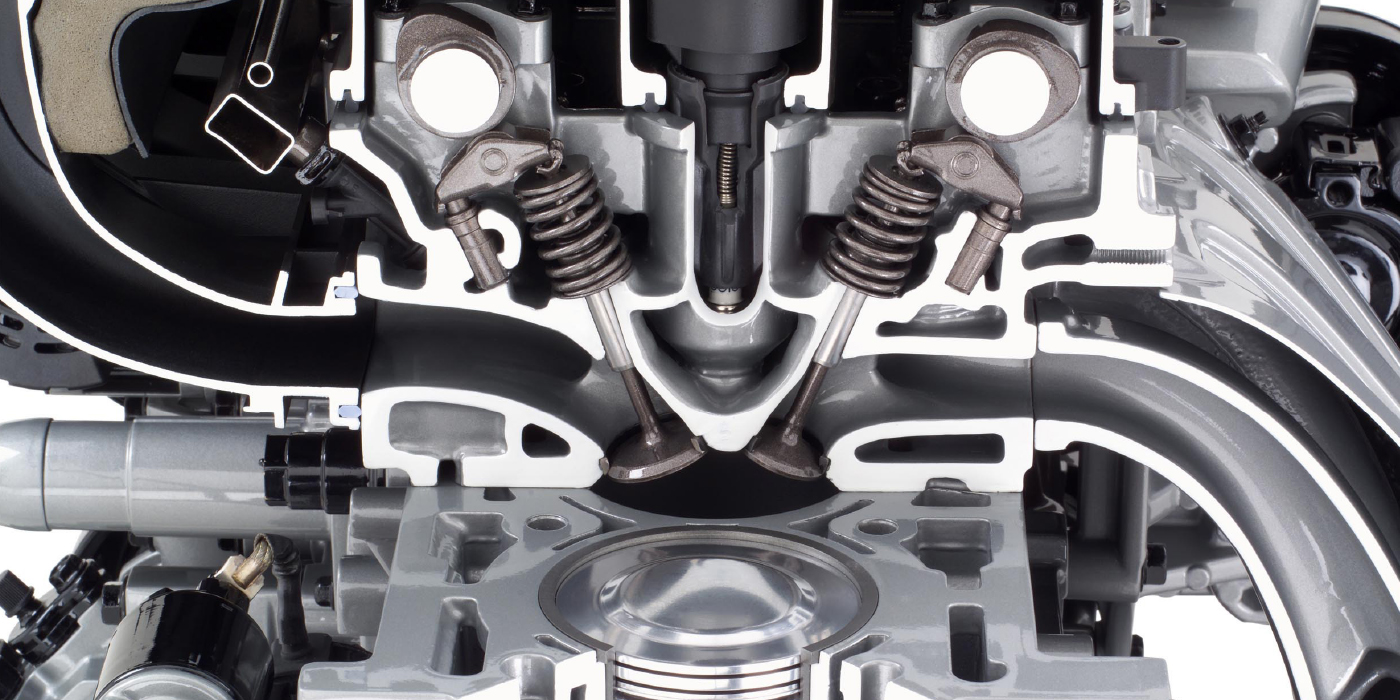

First, never, and I mean never install an axle fastener with an impact wrench. The repetitive shock from an impact wrench can cause permanent indentations in the bearing races, a common mechanical occurrence called brinelling. You can use an assistant to hold the brakes, and another common method is inserting a punch into a vented brake rotor and allowing it to rest against the caliper bracket.

Second, the torque specification is designed for far more than just keeping something tight. On these wheel bearings, it is designed to maintain the proper amount of preload in the bearing, which affects the geometry of the rolling elements to the bearing race. If this isn’t correct, the bearing simply won’t last as long.

Don’t forget the proper torque on the wheel lug nuts, and, last but not least, you should always perform a vehicle alignment when any suspension component is replaced.

This video is sponsored by GSP North America.