OBD II is primarily emissions-driven and will set codes anytime a vehicle has a fault that may cause emissions to exceed federal limits by 1.5 times. It doesn’t necessarily mean the vehicle has a real emissions problem. Many times it does not. But, if the nature of the failure is such that it might cause emissions to rise, OBD II will set a code anyway. That is why some states are allowing motorists to opt for a second-chance tailpipe test if their vehicle fails an OBD II test. In many instances, the vehicle will pass the tailpipe test.

One of the EPA requirements for using a plug-in OBD II check in lieu of a tailpipe test is to make sure the OBD II system is ready and has run its system monitors. Some vehicles have readiness issues when it comes to setting all the OBD II monitors.

When OBD II runs a self-check on a particular component or system, it lets you know by setting readiness flags, which are displayed on your code reader or scan tool. If OBD II has run all the available monitors and finds no faults, the MIL remains out and the vehicle passes the emissions test. But, if all the required monitors have not run, the vehicle can’t be given an OBD II test. The motorist must drive the vehicle and come back again, or take a tailpipe test, if that is an option.

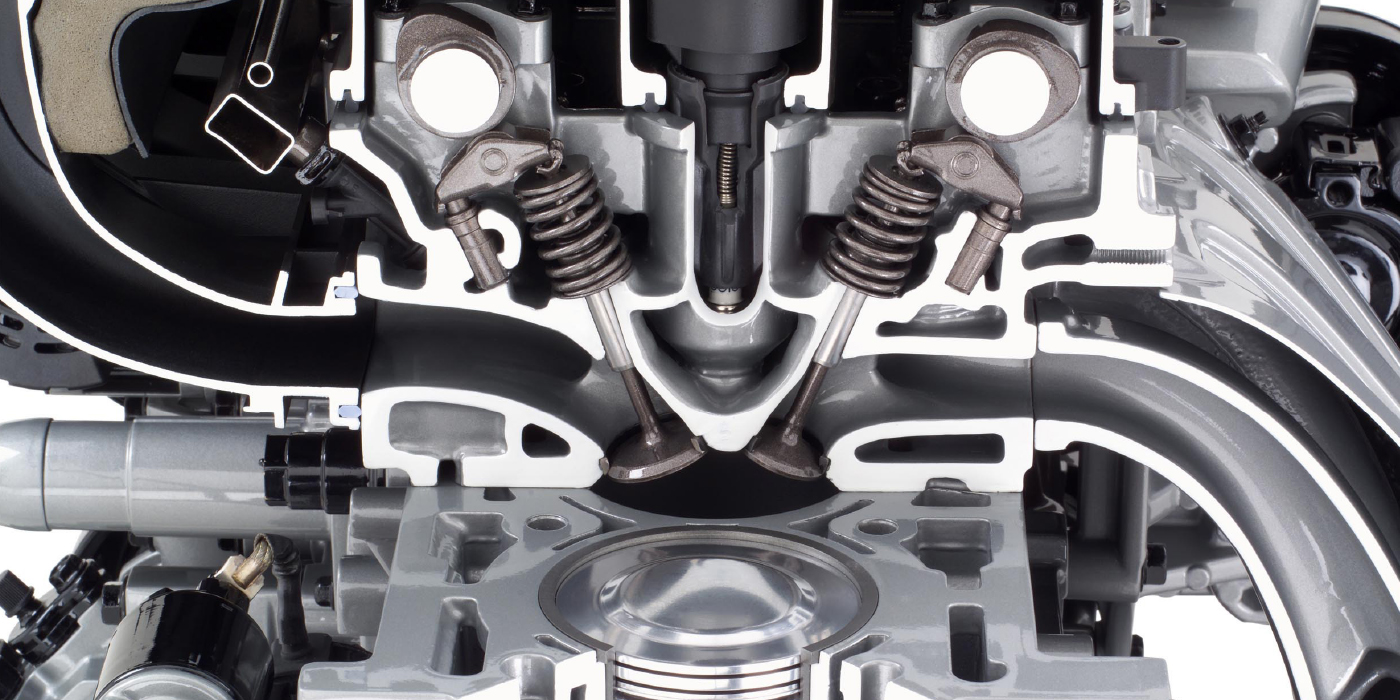

If OBD II detects a fault when running a monitor, the setting of a code may prevent the remaining monitors from running. A bad or slow oxygen sensor, for example, will prevent the catalyst monitor from running. Getting all the monitors to run can be tricky on some vehicles. Each monitor has certain operating requirements that must take place before the self-check will run.

To set the converter monitor, for example, the vehicle may have to be driven a certain distance at a variety of different speeds. The requirements for the various monitors can vary considerably from one vehicle manufacturer to another, so there is no “universal” drive cycle that will guarantee all the monitors will be set and ready.

Some vehicles require very specific drive cycles (called “drive traces” if you perform them on a road simulator or dyno) to activate certain self-checks like the catalyst and EVAP monitors.

If you are checking an OBD II system and discover that one or more of the monitors have not run, it may be necessary to test drive the vehicle to set the remaining monitors.

An OBD II drive cycle is not just turning the ignition key on and off or starting the engine. A drive cycle requires starting a cold engine and driving the vehicle until the engine reaches normal operating temperature. The next drive cycle doesn’t begin until the engine has been shut off, allowed to cool back down and is restarted again.

On some vehicles, the drive cycle also includes the cold soak time between trips. On some vehicles, the EVAP monitor won’t run unless the vehicle has not been run for eight hours. There is no way to bypass or get around such requirements, so you have to do whatever the system requires. And if that means waiting, you have to wait.

Other faults can cause a monitor from completing. For example, a faulty transmission shift position sensor can prevent the EVAP monitor from running. Also, communication issues that prevent the modules that share vehicle speed can also prevent a monitor from completing.

SCAN TOOLS

The right scan tool can be a Swiss Army Knife of functionality when trying to reset monitors or at least confirm the conditions that set the code are no longer present. Some information and tests can be done using global OBDII.

Some scan tools access certain OBD II modes in the global mode. These modes include:

- Mode $01: Used to identify what powertrain information is available to the scan tool.

- Mode $02: Displays freeze-frame data.

- Mode $03: Lists the emissions-related “confirmed” DTCs stored. It displays exact numeric, four-digit codes identifying the faults.

- Mode $05: Displays the oxygen sensor monitor screen and the tests.

- Mode $06: This type of information is a request for On-Board Monitoring Test Results for Continuously and Non-Continuously Monitored Systems. There is typically a minimum value, a maximum value and a current value for each non-continuous monitor.

- Mode $07: In this mode, the scan tool sends a request for emissions-related DTCs detected during the current or last completed driving cycle. It enables the external test equipment to obtain “pending” DTCs detected during the current or previous completed driving cycle for emissions-related components/systems. This is used after a vehicle repair, and after clearing diagnostic information to see test results after a single driving cycle to determine if the repair has fixed the problem.

The information might be difficult to decipher on certain scan tools, while some scan tools make the information easy to interpret. For example, Mode $05 and $06 can be critical for looking at the voltages coming from the oxygen sensors and see the switching of sensors and whether the ECU is actively controlling the fuel trim.

When you are looking for your next scan tool, the functionality of global mode should be at the top of your buying criteria. Even if the scan tool promises the latest coverage, the global OBD mode can be more versatile in curing emissions codes and resetting monitors.