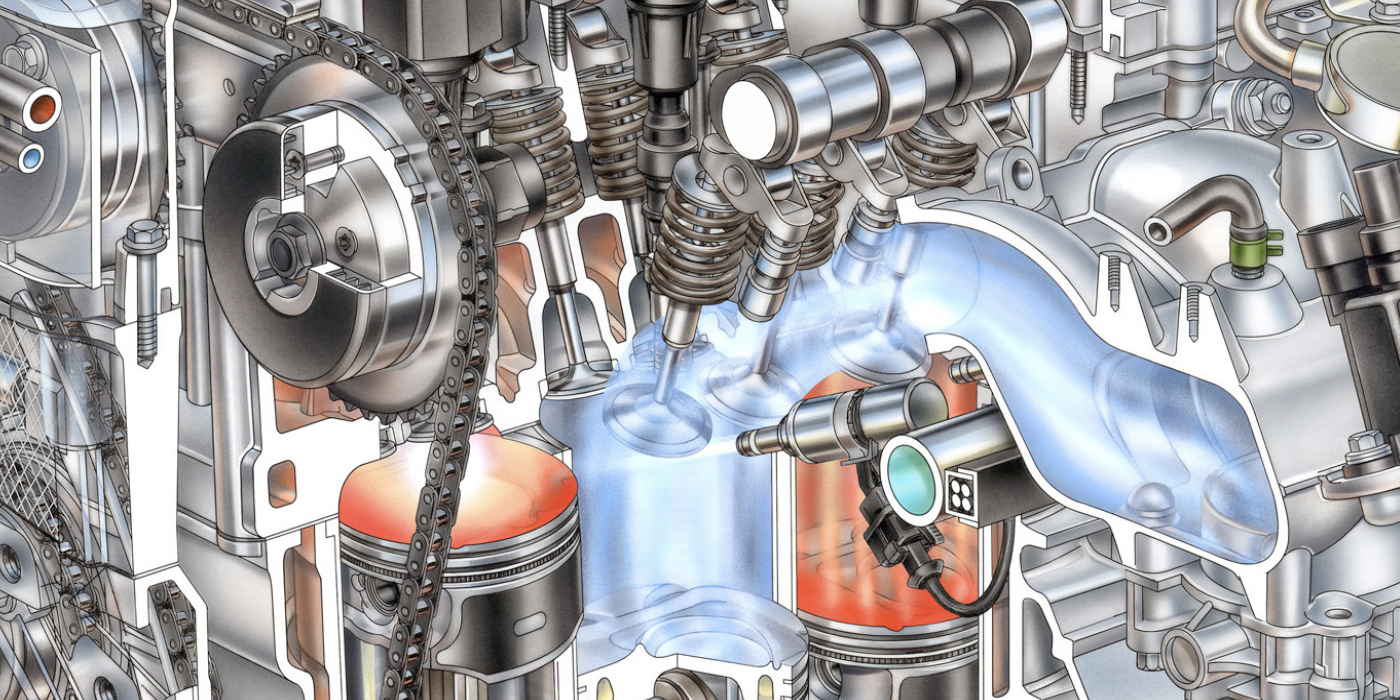

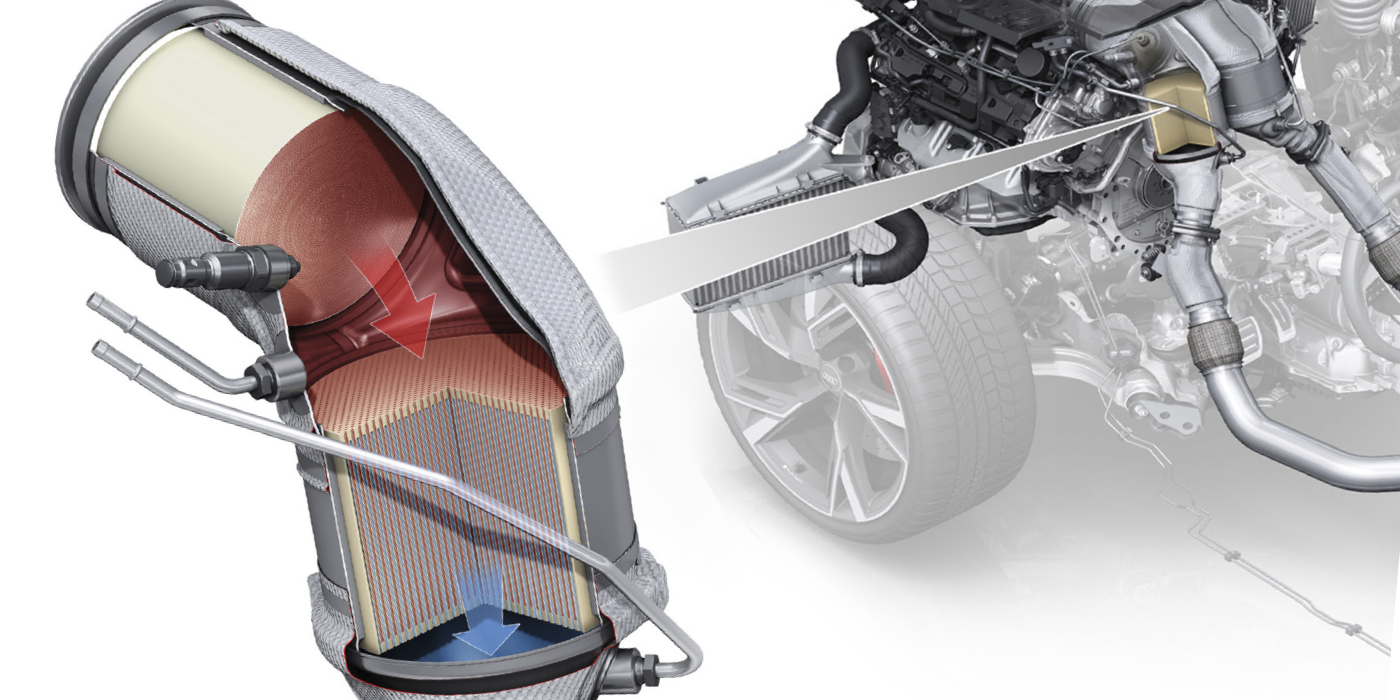

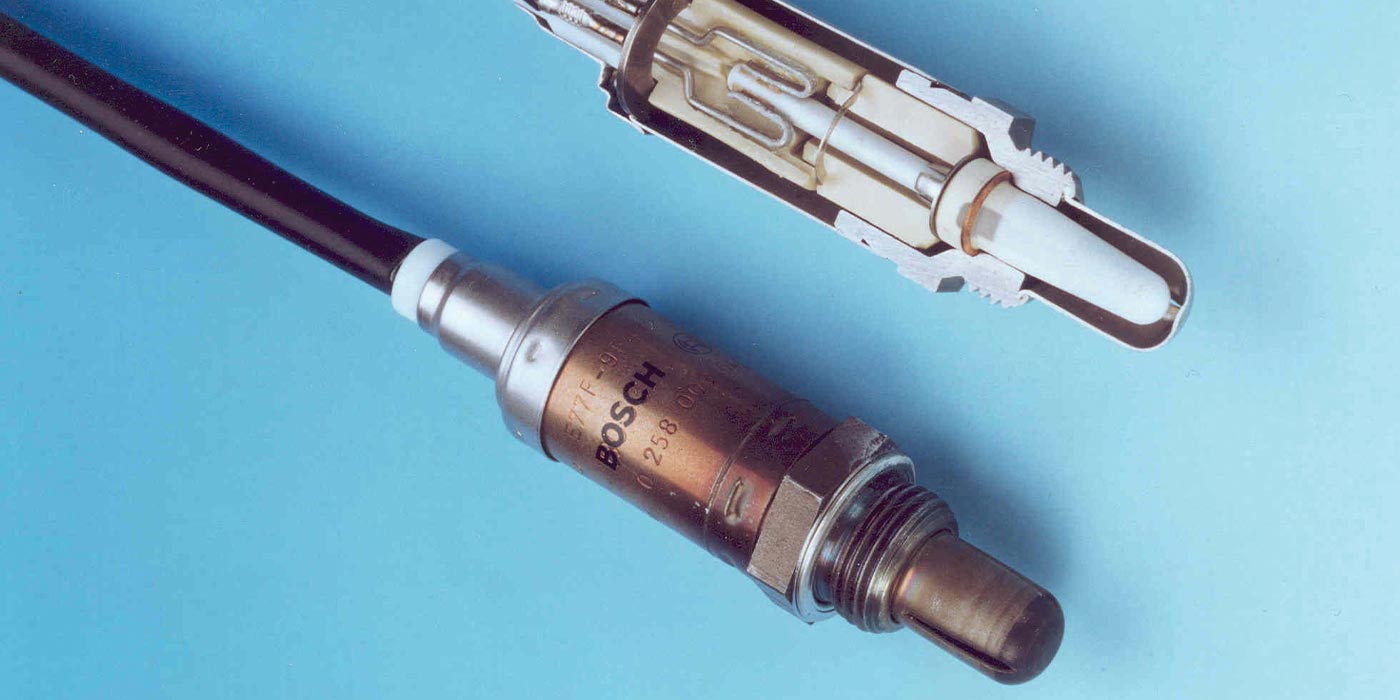

Today’s automotive engines are extremely sophisticated and are controlled by state-of-the-art onboard computers. If a sensor malfunctions, it can reduce fuel economy or negatively affect emissions. That’s why DENSO First Time Fit Oxygen and Air/Fuel Sensors are designed to meet or exceed the original equipment tolerances set by the manufacturers.

DENSO has just released its 2014 First Time Fit Oxygen and Air/Fuel Sensor Catalog that offers one of the most complete product lines in the industry. It includes 70 new sensor part numbers and covers an additional 3.6 million units in operation.

“Few people realize that the Oxygen and Air/Fuel Sensors are among the most sensitive and critical components on your car’s engine. To perform properly, these sensors must adhere to OE standards within incredibly close tolerances. DENSO First Time Fit sensors are designed to meet those tolerances and more,” said John Doran, senior manager, marketing and product management group. “To date, DENSO offers a total of 1,335 part numbers – 1,316 direct fit part numbers and 19 universal part numbers. That represents 99.9 percent coverage through the 2014 model year, which translates into more than 800 million units in operation.”

The DENSO product line covers nearly every light-duty vehicle manufacturer in the United States and Canada, according to DENSO, including additional 2014 model year coverage for Acura, Audi, BMW, Buick, Cadillac, Chevrolet, GMC, Honda, Infiniti, Lexus, Lincoln, Mercedes-Benz, Mini, Nissan, Porsche, Scion, Subaru, Toyota, Volkswagen and Volvo.

To make it easy to find the correct sensor, the 2014 First Time Fit Oxygen and Air/Fuel Sensor Catalog includes applications by manufacturer, reference information on new numbers, supersessions, universal sensors, complete photo guide by part number, buyer’s guide by part number, cross-reference by competitor and UPC barcode reference.

To obtain a copy of the 2014 Oxygen and Air/Fuel Sensor catalog or any other DENSO catalog, contact your local DENSO representative or call 1-888-96-DENSO (Option 2).