Delphi Product & Service Solutions has announced the addition of five new mass airflow sensors (MAF) covering nearly 1 million vehicles built from 1990 to 2013. Applications cover manufacturers including Nissan, Audi, Toyota and Infiniti. New part numbers include: AF10198, AF10209, AF10214, AF10218 and AF10221.

What MAF Sensors Do

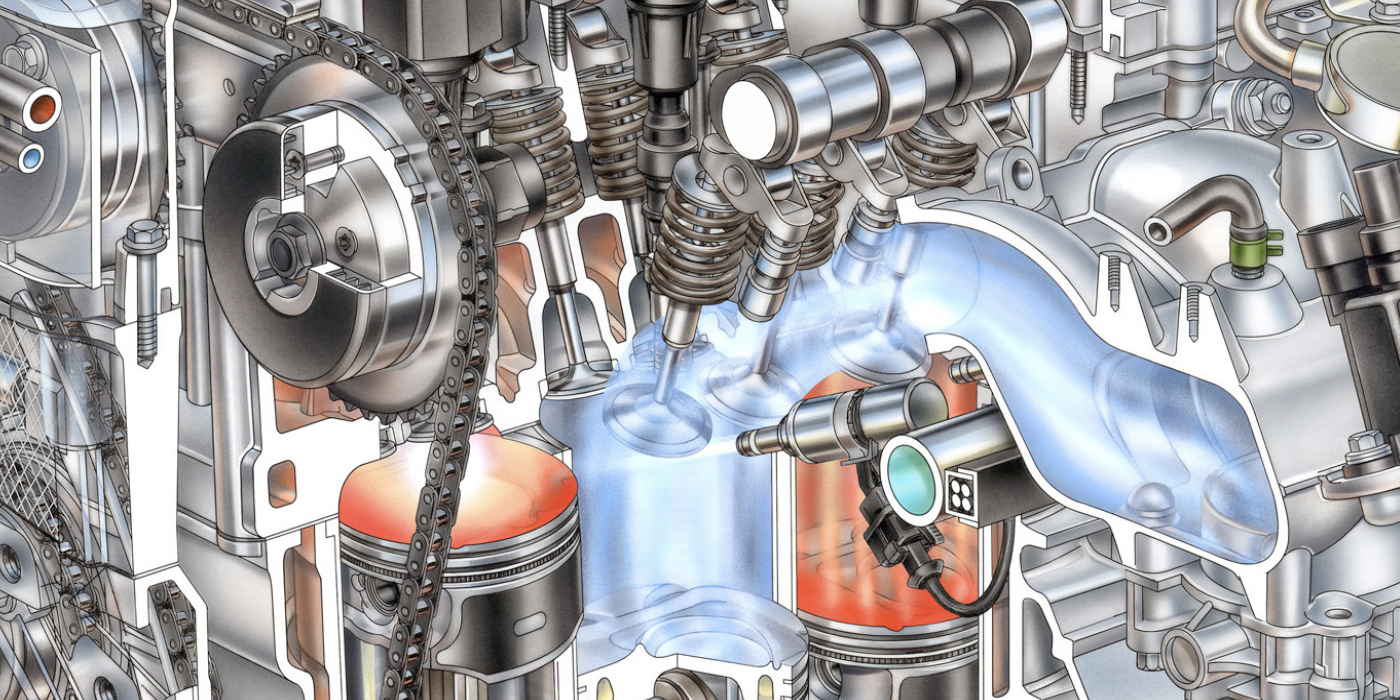

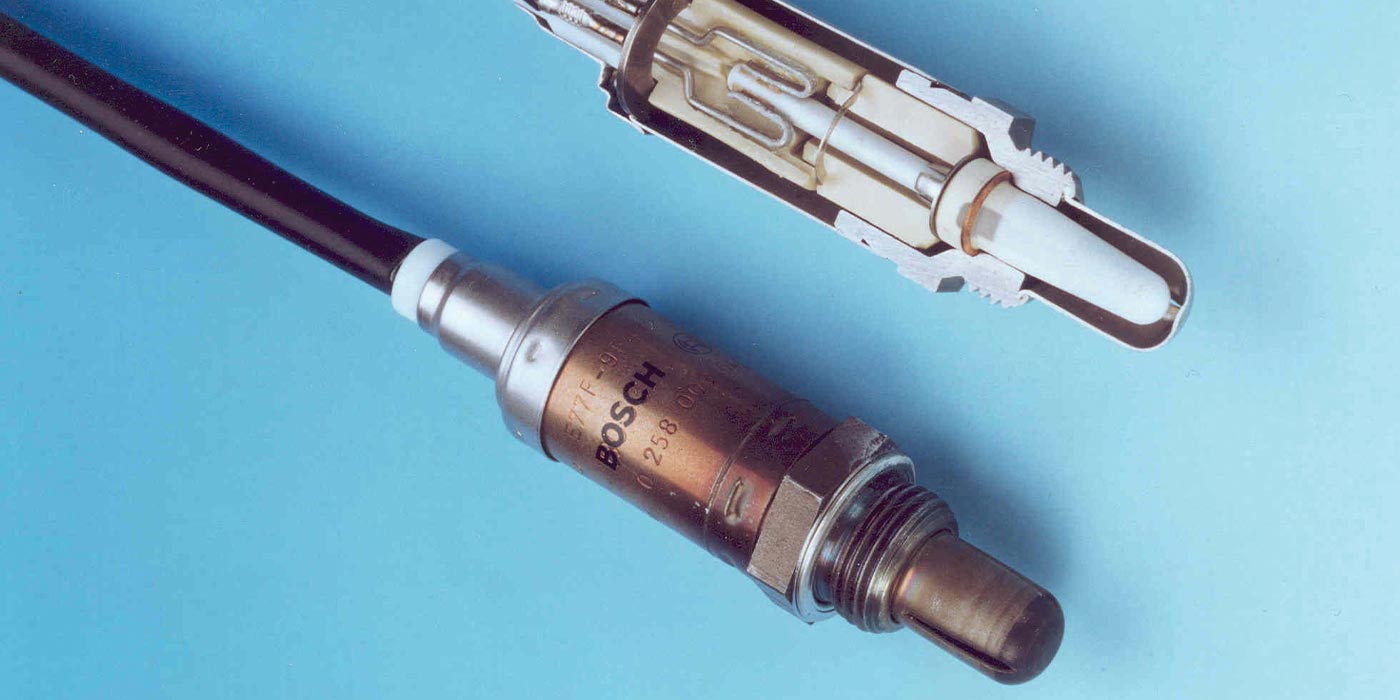

MAF sensors measure intake airflow and send this information to the ECU. When the ECU receives the information from the MAF sensor and oxygen sensors, it makes adjustments to the amount of fuel being injected into the engine to compensate for excess air or excess fuel.

According to Delphi, when a Delphi MAF sensor is used in combination with Delphi oxygen sensors, the engine’s air/fuel ratio can be controlled much more accurately. All of these functions ensure accurate air/fuel ratio for optimal engine performance in any driving condition.

Why Sensors Fail

Contamination is a key reason why MAF sensors fail and require replacement. As air, dirt and other debris get into the sensor, the parts become contaminated and result in failure. Drivers often notice sluggish performance or a more frequent need to refuel.

Delphi offers three reasons to choose Delphi Mass Airflow Sensors:

1. All New Products Go Through Stringent OE Testing

Delphi MAF sensors are brand-new, never remanufactured. All parts are tested and calibrated to OE standards using highly accurate OE equipment. By testing to OE specifications, Delphi ensures that the sensors provide accurate readings and airflow output, which helps to reduce comebacks.

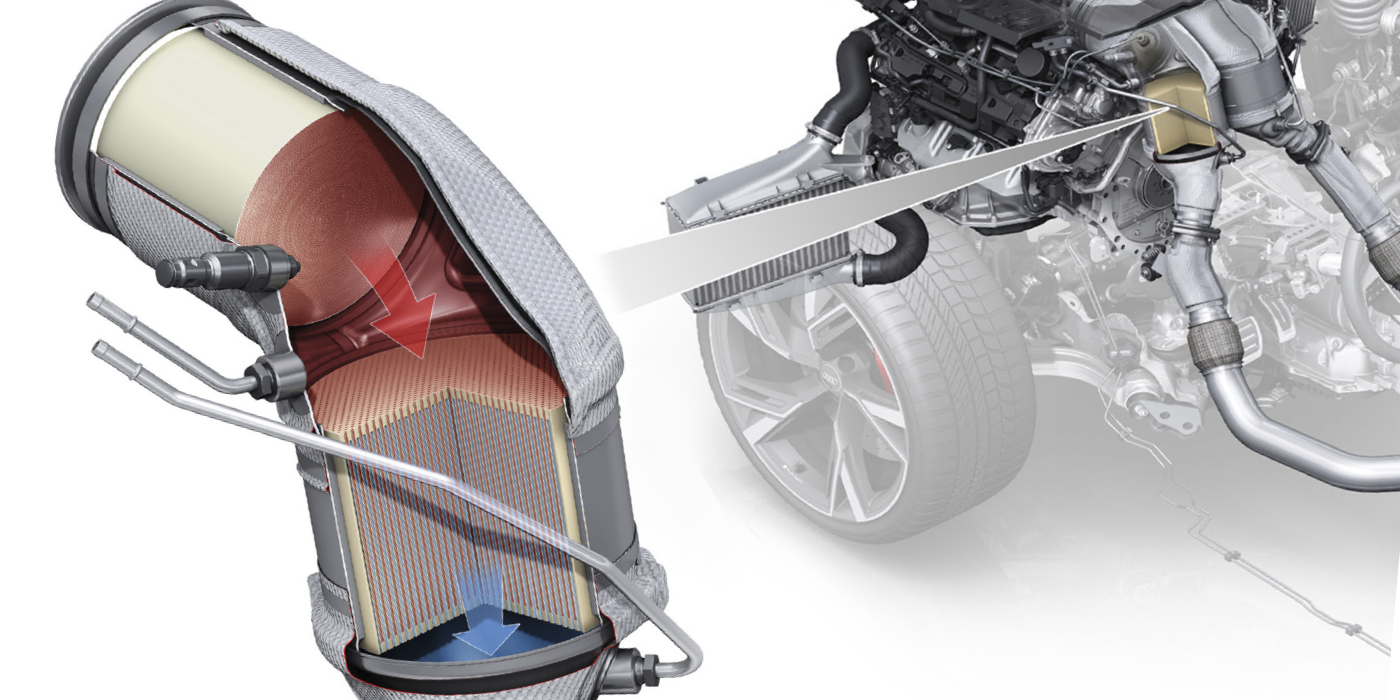

2. No Flow Tubes Mean Less Storage Space and a Greener, Quicker Repair

Delphi’s direct sensor solution allows technicians to focus on the part that needs to be replaced. The company says that 98 percent of the time it is the sensing electronics in the probe that fail. By eliminating the need to replace the plastic flow tube, Delphi provides a greener repair solution.

3. Clam Shell Packaging Protects the Product

Shops receive Delphi Mass Airflow sensors in a plastic clamshell, which helps protect the sensing elements from damage.

Delphi MAF Sensors are built with the benefit of more than 100 years of OE heritage. They are designed and manufactured with Delphi resistors and calibrated to the OE specifications to ensure every part has the correct fit, form and function.

Inventory will be available in the third quarter of 2014. Visit go.delphi.com for specific part information.