The first thing to remember is that all brakes make noise. When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. In engineering terms, this is called “force coupled excitation,” which means that the components are locked as a combined system that will vibrate at the system’s natural frequency combined modes of vibration. The driver hears these vibrations as noise. This is “ground zero” for brake noise.

The first thing to remember is that all brakes make noise. When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. In engineering terms, this is called “force coupled excitation,” which means that the components are locked as a combined system that will vibrate at the system’s natural frequency combined modes of vibration. The driver hears these vibrations as noise. This is “ground zero” for brake noise.

In layman’s terms, when the pads press into the rotors, it makes a vibrations that becomes noise. Like dogs, humans have a limited range of sounds they can hear. If the noise is out of the range of human ears, there will not be a noise complaint or comeback (this is typically high-frequency noises). It is when these vibrations are allowed to transfer into the caliper and knuckle where they are lowered to the human hearing ranges, that the driver notices a noise.

Brake shims are not designed for adjusting spacing/distance between friction material and the rotor. Shims provide multifunction noise control as a component attached to the friction pad backing plate. A quality brake shim can prevent brake noise during the entire life of the brake job and will not dry out or be displaced over time like some lubricants. But remember, a shim does not do its job if it is left in the box.

Brake shims have the ability to control noise in three ways. First, they prevent and reduce the transmission and amplitude of vibrational forces that cause excitation of the caliper, pad assembly and attached structure. This is accomplished by visco-elastic damping material inherent within the layering construction of the shim and method of bonding to the pad assembly.

Brake shims have the ability to control noise in three ways. First, they prevent and reduce the transmission and amplitude of vibrational forces that cause excitation of the caliper, pad assembly and attached structure. This is accomplished by visco-elastic damping material inherent within the layering construction of the shim and method of bonding to the pad assembly.

In layman’s terms, it prevents vibrations that start at the pad and rotor from being transferred into the caliper and knuckle. These vibrations are very small and hopefully the shim can isolate a vibration before it excites the caliper and knuckle.

In layman’s terms, it prevents vibrations that start at the pad and rotor from being transferred into the caliper and knuckle. These vibrations are very small and hopefully the shim can isolate a vibration before it excites the caliper and knuckle.

Second, a shim can add mass to the brake pad that can dampen vibrations and oscillations in the pad and caliper. Shims reduce reaction forces transmitted back into the brake piston using elastomer interface coatings on their surface.

Third, a good brake shim or insulator can act as a thermal barrier to ensure consistent temperatures across the entire face of the pad. This can help ensure consistent brake torque.

High-quality brake shims are frequency and temperature engineered multi-layered products using varying grades of metal, viscoelastic polymers/bonding materials, elastomeric rubbers and fiberglass.

High-quality brake shims usually start with a high-quality metal plate. The shim manufacturer will select a grade of steel with the right hardness, thickness and dampening properties.

The elastomeric rubbers are applied to the steel in a controlled process that ensures the correct depth. These materials are then vulcanized to the metal to ensure that they will endure the harsh environment of the braking system.

Engineers tune these layers to give the best NVH qualities for the specific brake system noise fingerprint orsignature.

If the shim is not making contact with the brake pad, it will not do its job since the pad/caliper assembly undergoes complex dynamic vibrational deformations due to superposition of the combined system natural frequency mode shapes that must be controlled by a properly attached insulator.

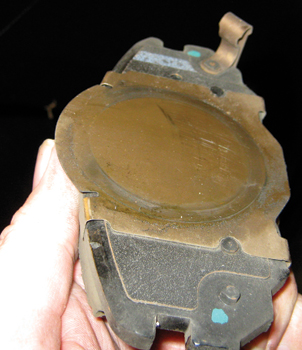

Before you install any brake pad or shim, take time to look it over. Look at the overall finish and appearance of the parts, test fit the part to see if the tolerances are correct. Some of the best brake pads have the insulator already attached to the pad set. This can help ensure the effectiveness in three ways.

First, by putting the shim on at the factory it can prevent the technician from forgetting to put them on the pad in a dirty shop environment. Second, some pad and shoe manufacturers will use a heated hydraulic press that can properly cure the adhesive. Third, the brake pad manufacturer can use a process like peening and riveting to make sure the shim will perform properly.

If the shim/insulator is not already attached to the pad, drop it on a hard surface and listen. If the shim makes a clinking noise and bounces around, chances are that it will not reduce noise and vibration. If the shim makes a solid noise when it is dropped, it probably will do a good job at insulating against noise.

If a set of pads or shims do not look “right,” do not take a chance by installing them. It is easier to return opened unused brake pads then those that have been slightly worn.

Blame Game

It is easy to blame the pads when you have a comeback due to noise. When a customer hears a brake noise, it is not just the “pure” sound of the friction coupling. The sound they are hearing is a product of the entire brake system, structural transfer paths through suspension components into the passenger compartment and amplified noise within the reflective wheel well acting as a reverberant echo chamber.

This is why it is important to look at the entire system when it comes to diagnosing brake noise.