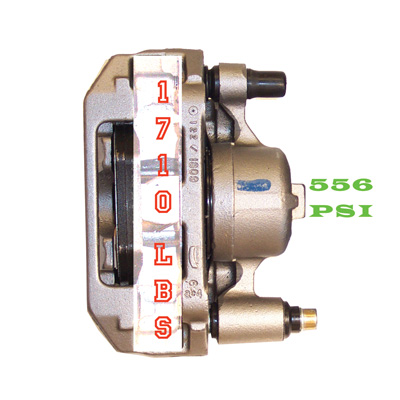

If the calipers are a single piston floating design with a two-inch diameter pistons (piston surface area = pπR2 x 2), we just multiply pistons surface area by 556 psi and surface area and we get a 3,419 lbs. of clamping force at both front calipers!

In our theoretical example above, we are ignoring some real world factors that influence the amount of clamping force. The reality of it is that not all of the 556 psi makes it to the caliper and some of the force is wasted flexing the caliper and compressing the brake pads.

While the brake fluid is traveling from the master cylinder to the calipers, it is pushing on the walls of the brake lines and hoses. This means that some of the pressure or pedal effort is lost. This is why engineers try to keep the amount of flexible hose to a minimum. Also, this is why race cars use braided flexible like to reduce compliance.

Even if all of the pressure makes it to the caliper piston, some of the generated force is lost as the caliper flexes. This flexing can occur at the bridge or mounting points. Most floating caliper designs can have more flex. Opposed piston designs are typically stiffer. But, if the input pressure and piston area is the same for both designs, the calipers will generate the same theoretical forces.

If you try to improve a system by changing to larger calipers with more piston surface area or change the diameter of the master cylinder, you are upsetting the balance.

One of the advantage of four, six or even eight piston calipers is the ability to generate the force more evenly over a larger backing plate.

Another factor in the system is the brake pad and how it acts under the force. If the backing plate flexes, braking force is lost as the friction area flexes and changes.

Inexpensive brake pads will often have thinner backing plates to save on steel. This is leading reason why they can cause a soft or low pedal. It gets even worse if the manufacturer is putting large holes in the backing plate for molding or riveting. Some mechanical attachment designs can eliminate these holes. Another benefit to having a ridged backing plate is less brake noise because the friction surface is more stable and consistent.

The clamping forces are used to generate friction that produces torque to stop the vehicle. This is where “coefficient of friction” comes into play. Basically, the coefficient of friction is calculated by dividing the force required to slide an object over a surface by the weight of the object. For example, if it takes 100 pounds of force to slide a 100-pound brake pad over a rotor, the coefficient of friction between the two materials is 1.0.

Clamping forces and the coefficient of friction are on one side of the equation and brake torque is on the other side. If you increase either variable, you are changing the amount of torque the system can generate.

In essence, engineers balance coefficient of friction with piston and master cylinder sizes to give the vehicle the right amount of stopping force and pedal feel. If you increase or decrease the coefficient of friction, you might be upsetting the balance.

Toyota FJ Cruiser Water Pump Replacement

Toyota’s original Land Cruiser was the company’s version of a Jeep that could go anywhere. In its time it was highly rated and collected, which led the Japanese juggernaut to bring back an updated SUV in 2007 called the FJ Cruiser. The retro-styled vehicle was again a go anywhere machine powered by a 4.0L V6 (1GR-FE) used in the Tacoma. The engines are durable and considered relatively robust for the time.

Toyota’s original Land Cruiser was the company’s version of a Jeep that could go anywhere. In its time it was highly rated and collected, which led the Japanese juggernaut to bring back an updated SUV in 2007 called the FJ Cruiser. The retro-styled vehicle was again a go anywhere machine powered by a 4.0L V6 (1GR-FE) used in the Tacoma. The engines are durable and considered relatively robust for the time.

Long-Life Coolants Explained

Different types of coolants cover a range of applications from diesel to domestic, Asian and European vehicles. Each one is formulated to a specific manufacturer’s specifications to keep their engines at an optimal temperature. But, changes to the old one-size-fits-all formula has led to confusion for consumers and even some technicians.

VIDEO: Engine Efficiency Brings More Hoses

Andrew Markel discusses hoses and the necessity for several of them to route fluids to all parts of the vehicle due to the growing efficiency of engines. Sponsored by Dayco.

Diagnosing Intelligent Cooling Systems

The majority of cooling systems on the roads react to what is happening inside the combustion chamber. After the engine is stressed, the heat causes the thermostat to open. Increases in temperatures will also cause the cooling fans to come on. The heat carried by the coolant is the trigger for operation of the fans and thermostat.

Modern Cooling System Design: It’s Not About Temperature; It’s About Powertrain

Given the advanced state of internal combustion engine technology, some recent cooling system innovations will actually increase engine torque and fuel economy while reducing exhaust emissions. Let me simplify that idea: new cooling system technology will make engines run better and cleaner. So, let’s get on the same page by reviewing some basics.

Other Posts

Why Does Engine Coolant Need Replacement?

Two specifications can be used to justify replacement — the condition of the additive package & the freezing point.

Improving Turbocharger Longevity

It is estimated that by 2022, 50% or more of vehicles sold in the U.S. will have one or more turbochargers under the hood.

Engine Cooling System: Hose Inspection and Replacement

One bad hose can cause an engine malfunction. This video is sponsored by Continental.

VIDEO: Power Steering Systems That You Might Encounter

There are three types of power-steering systems today. This video is sponsored by The Group Training Academy.