The 2000-2005 GM H platform, or H-body, designates a General Motors front-wheel drive full-sized automobile platform. (The chassis identification can be found on the 4th letter of the VIN.) The H-body sedans were the next “big thing” for GM with development costing more than $3 billion to bring it to market. In the 2000s, the H-body designation began to be used for a re-engineered platform based on the GM G platform (FWD). This platform was used for the Buick LeSabre/Lucerne and Pontiac Bonneville.

The 2000-2005 GM H platform, or H-body, designates a General Motors front-wheel drive full-sized automobile platform. (The chassis identification can be found on the 4th letter of the VIN.) The H-body sedans were the next “big thing” for GM with development costing more than $3 billion to bring it to market. In the 2000s, the H-body designation began to be used for a re-engineered platform based on the GM G platform (FWD). This platform was used for the Buick LeSabre/Lucerne and Pontiac Bonneville.

BLEEDING

BLEEDING

Bleeding of the H-body’s hydraulic system can be performed manually, power bled, gravity bled or using reverse fluid injection. The bleeding sequence is: right rear, left front left rear and right front.

If the pedal is still soft, you can perform an automated bleeding procedure with a scan tool that will force air from the ABS system. The procedure cycles the system valves and runs the pump in order to purge the air from the secondary circuits normally closed off during normal base brake operation and bleeding. The automated bleed procedure is recommended when air ingestion is suspected in the secondary circuits, or when the BPMV has been replaced.

The Auto Bleed Procedure may be terminated at any time during the process by pressing the EXIT button. No further Scan Tool prompts pertaining to the Auto Bleed procedure will be given. After exiting the bleed procedure, relieve bleed pressure and disconnect bleed equipment per manufacturer’s instructions. Failure to properly relieve pressure may result in spilled brake fluid causing damage to components and painted surfaces. Before starting the procedure, make sure the battery is fully charged.

FRONT BRAKES

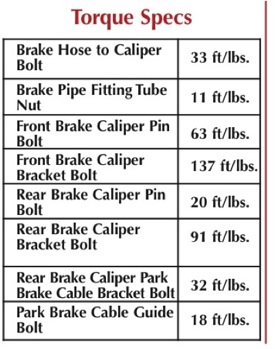

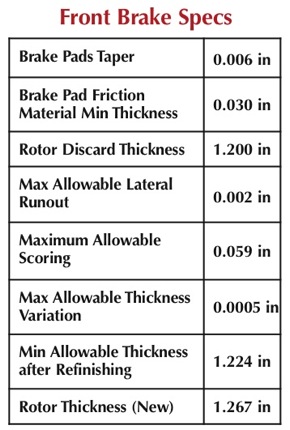

The front brakes on the H-body use single-piston floating caliper. To inspect the pads or to just replace the pads, remove the lower caliper pin bolt and rotate the caliper upwards.

The front brakes on the H-body use single-piston floating caliper. To inspect the pads or to just replace the pads, remove the lower caliper pin bolt and rotate the caliper upwards.

Pay attention to the caliper piston boot and slide boots. When reinstalling the boots, make sure the boots seat to the grooves on the bracket and bolt. GM does not recommend lubricating the brake pad hardware, but a very light coating (barely visible) of moly-based lubricant on hardware can reduce noise comebacks.

When servicing the rotors, make sure the flange is free of corrosion and debris. Small amounts of corrosion can cause up to .001” of lateral runout on a “perfect” rotor.

REAR BRAKES

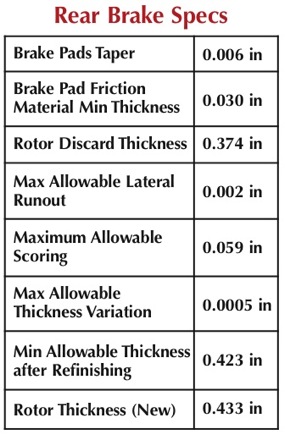

The rear brakes use a single-piston floating caliper that is also the emergency brake. Like the front brakes, pay attention to the details like hardware and torque specs.  The only special procedures involve retracting the piston and resetting the new pads against the rotor.

The only special procedures involve retracting the piston and resetting the new pads against the rotor.

1. Using a large C clamp, compress the brake caliper piston into the brake caliper bore to gain enough clearance to allow the brake caliper to pivot off the brake caliper bracket.

2. Compress the piston until resistance is felt, but no more than 1 mm (0.039 in) of piston travel.

3. Remove the park brake cable guide bolt from the lower control arm.

4. Remove the lower caliper pin bolt and rotate upwards.

5. Turn the piston clockwise until it bottoms in the brake caliper bore and align the piston.

6. Align the cutouts in the brake caliper piston to the  alignment pins on the brake pads. Then seat the pads to the rear rotors, with the engine OFF, gradually apply the brake pedal to approximately 2/3rds of its travel distance and slowly release the brake pedal. Wait 15 seconds. Repeat until a firm brake pedal is obtained. This will properly seat the brake caliper pistons and brake pads.

alignment pins on the brake pads. Then seat the pads to the rear rotors, with the engine OFF, gradually apply the brake pedal to approximately 2/3rds of its travel distance and slowly release the brake pedal. Wait 15 seconds. Repeat until a firm brake pedal is obtained. This will properly seat the brake caliper pistons and brake pads.

MORE BRAKE JOBS:

Brake Job on 1995-2004 Toyota Tacoma

Tech Feature: 2004-2008 Nissan Maxima Brake Job

Tech Feature: 2004-2008 Nissan Maxima Brake Job

BRAKE JOB: Seventh Generation Accord (2003-’08)

BRAKE JOB: Seventh Generation Accord (2003-’08)