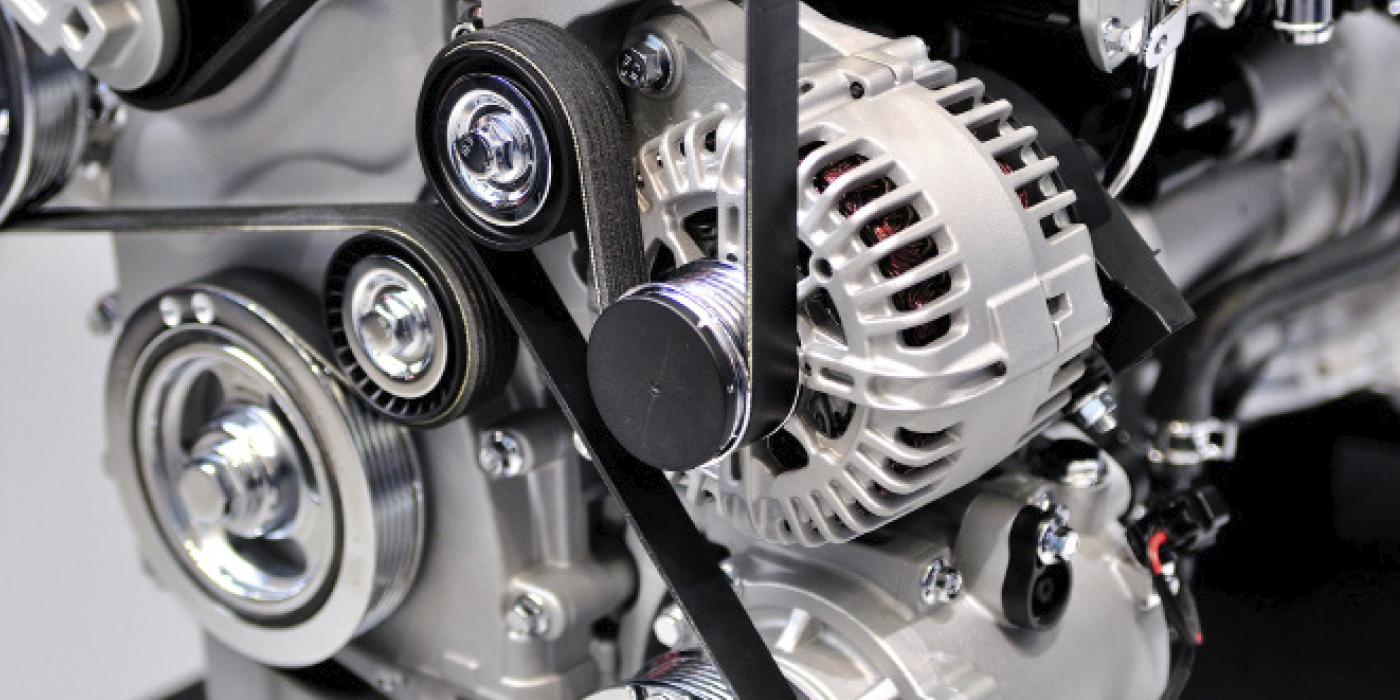

One of the noisiest components under the hood of a vehicle can be the belt and the drive components. Noise is not the fault of the belt, but the result of how the power comes from the crankshaft and the components attached to the belt.

No internal combustion engine has a constant crankshaft speed. An engine slows down as the piston compresses the air and fuel mixture and speeds up as the mixture is ignited. You can’t see it with the naked eye but the small, sudden changes in speed can cause slipping, noise and unwanted movement in the belt. So, what is an engineer to do?

The first option to control noise is to increase the tension of the belt. When the amount of tension is raised on the belt with either a manual adjuster or automatic tensioner it can do three things to the belt. First, it makes the belt drive system less efficient because it takes more power to drive the components. Second, as belt tension increases the wear on the belt can increase. Third, higher tension levels put more stress on the bearings in the alternator, power steering pump and idler pulleys. For engineers, belt tension is a balancing act between noise, efficiency and longevity of the belt.

There are other engineering options to that balance without increasing tension on the belt. Harmonic balancers on the crankshaft can dampen crankshaft speed changes at the sources. Alternator decoupler pulleys can decouple the alternator from the drive belt system, and some can even dampen vibration. Also, new automatic belt tensioners have dampening components that can keep the tension constant.

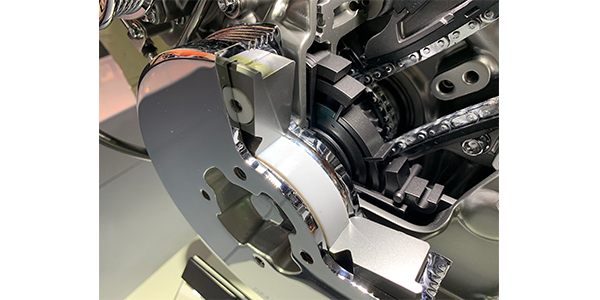

Harmonic Balancers

A harmonic balancer is like a punching bag for the crankshaft. There are two primary components in a harmonic balancer: inertial mass and an energy-dissipating element. The inertial mass consists of an outer ring that could have the grooves for the belts and an inner hub that connects to the crankshaft. The outer ring contains the mass to dampen the small changes of speed in the crankshaft.

Between the two metal components is the energy-dissipating element, which is a rubber or elastomeric compound. This ring of rubber can cause the two metal parts to go out of phase as much as 1º to 2º as it absorbs the vibrations in the crankshaft. When the energy-dissipating element flexes, it changes the motion into heat.

What to Look For:

• Incorrect timing marks is a sign the outer ring has separated from the inner ring.

• Worn edges on the belt can be a sign the outer ring is no longer aligned with the rest of the accessories’ pulleys.

• If you have an odd engine vibration and no misfire codes, check the dampener for damage.

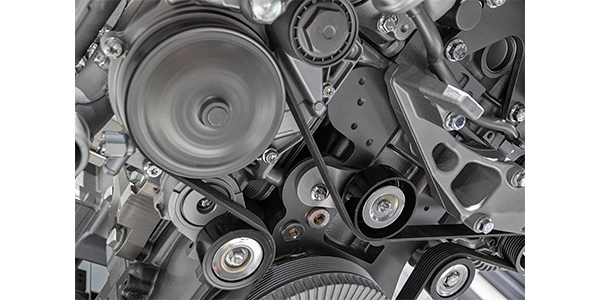

Automatic Belt Tensioner

A worn automatic belt tensioner has consequences beyond a loose belt. When an automatic belt tensioner wears out, the belt and attached accessories will start to take an extra pounding because the tensioner can no longer dampen the power pulses of the crankshaft. The effect on these components is similar to when a car has bad shocks that slowly destroy the suspension.

What to Look For:

• Look at the gap between the arm and body. If the gap is uneven, it is a sign the bearings that hold the shaft have failed.

• Look for rust deposits on the outside of the body and arm. The rust is typically from the spring and other internal components.

• Remove the belt and spin the pulley on the tension. Worn bearings can cause noise and alignment problems.

Decoupler Pulleys

Many late-model vehicles are equipped with special pulleys that are engineered to reduce noise, vibration, and harshness and extend the life of the alternator.

An Overrunning Alternator Pulley (OAP) has a one-way clutch mechanism inside the hub that allows the belt to turn the alternator in one direction and allows the alternator to “freewheel” and spin at its own speed when the engine suddenly decelerates.

A good OAP pulley should lock up and turn the alternator rotor when it is turned one way, but release and freewheel when it is spun in the opposite direction. If the internal clutch mechanism is bad, the pulley may slip and fail to drive the alternator, or it may remain locked all the time — increasing noise, vibration and stress on the belt drive system.

Another type of special pulley is an Overrunning Alternator Decoupler (OAD). This type of pulley also has a one-way overrunning clutch inside the hub, as well as an internal torsion spring to further dampen vibrations in the belt drive system. The spring acts as a shock absorber to cushion the hub. This reduces noise at idle and low engine speeds and helps dampen harmonic vibrations at higher speeds.

How can you identify these types of alternator pulleys? OAP and OAD pulleys usually thread onto the alternator shaft. Solid pulleys typically slide onto the alternator shaft or are press-fit and held in place with a large bolt on the end of the shaft.

What to Look For:

• Raise engine speed to 2,000-2,500 rpm in Park (auto trans) or Neutral (manual trans) and then shut off the engine. Listen for any noises from the OAD after the engine is shut off. A worn-out bearing will generate a “buzz” noise during this test. If the OAD is noisy during this test, replace it.

• Remove the cap, and with the proper tool inserted into the front of the OAP, rotate the alternator’s shaft in both directions. In the overrun direction it should feel smooth, and in the drive direction, it should have a spring feel.

- If the pulley is locked up, replace it.

- If the OAD has no spring feel in the drive direction, replace it.

- If the OAD requires more than 9-13 in./lbs. (1-1.5 Nm) of torque to turn in the overrun direction, replace the OAD.

- If the OAD is not smooth in the overrun direction, replace it.