Applied vehicle: 2000 Altima (L30), vehicles built before: 1N4DL01**YC119318 (Sept. 16, 1999)

Use the information in this bulletin to repair a vehicle built prior to the applied VIN and date if the vehicle has DTC P0335 (Crankshaft Position Sensor [CKPS] [OBD]) stored in Self-Diagnosis Results.

Service Procedure:

1. Perform Self-Diagnosis using CONSULT-II.

2. If there is a DTC stored in addition to P0335, diagnose and repair the additional DTC(s) first, using the appropriate service manual procedure(s).

3. After diagnosing and repairing the vehicle for the non-P0335 DTC, or if P0335 is the only DTC, use the following diagnostic procedure to determine if the incident is related to the CKPS (OBD) or associated electrical circuit:

Diagnostic Procedure:

Harness/Sensor Resistance Check:

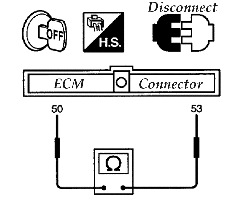

1. Disconnect the ECM harness connector (F30).

2. Connect a digital voltage-ohm meter (DVOM) to ECM terminals 50 and 53 (see Fig. 1).

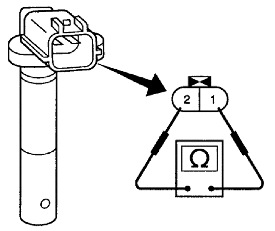

3. While shaking the EFI harness (see Fig. 2), is the resistance always between 512 and 632 ohm?

– If yes, go to Harness Grounding Check.

– If the DVOM does not indicate the above resistance, check the CKPS and harness as follows:

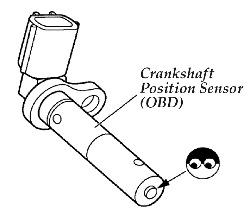

a. Disconnect the CKPS harness connector (F12).

b. Remove the sensor and visually check the sensor tip for chipping or damage (Fig. 3).

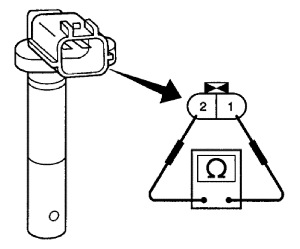

c. Check resistance with a DVOM. Resistance should be between 512 and 632 ohms (Fig. 4).

d. If sensor resistance is NG, replace the CKPS.

e. If sensor resistance is OK, reconnect the CKPS and repeat Steps 2 and 3.

– If resistance from Step 3 is not between 512 and 632 ohm, replace the harness.

– If resistance from Step 3 is OK, go to Harness Grounding Check.

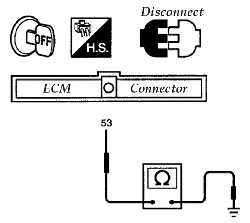

Harness Grounding Check:

1. Connect the DVOM to ECM connector (F30) terminal 53 and ground with the CKPS disconnected (Fig. 5).

2. While shaking the EFI harness (Fig. 2), check for continuity to ground.

– If continuity to ground exists, replace the harness.

– If continuity to ground does not exist, proceed to Step 3.

3. If the cause of DTC P0335 cannot be determined through the above Diagnostic Procedure, the DTC may have been stored due to one of the following conditions:

a. Turning the ignition off with the automatic transmission selector in a position other than “P” or “N,” then immediately re-starting the engine.

b. Turning the ignition off with a low or weak battery and high electrical load items (headlights, window defroster, blower motor) operating, then immediately re-starting the engine.

c. Engine stoppage caused by not fully depressing the clutch pedal with the manual transmission in gear when coming to a stop, then immediately re-starting the engine.

4. Erase the stored DTC P0335 from Self-Diagnosis Results using CONSULT-II.

5. Advise the customer that the vehicle was operated under one of the conditions noted in Step 3.

Courtesy of Mitchell 1.

Courtesy of Mitchell 1.