By Jim Tapp

By Jim Tapp

Most people think of an outside micrometer when they hear the term "micrometer." An "outside micrometer" is one that measures the outside of something such as diameter, length or thickness.

There are other types of micrometers, including depth micrometers and inside micrometers. As the names imply, they measure depth and the inside diameters, respectively. Often other tools (such as bore gauges) are used with micrometers to determine sizes so knowing how to read the micrometer is absolutely necessary.

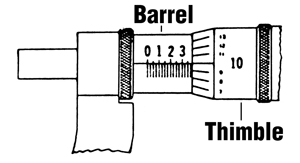

A micrometer is a measuring gauge operated by a screw with 40 threads per inch. This means that one complete revolution of the screw advances one thread or one-fortieth of an inch. 1/40˝ equals 25 thousandths of an inch or 0.025˝ (40 x .025˝ = 1˝). The beveled edge of the thimble is divided into 25 equal parts. Each line of the micrometer’s thimbles equals 1/25 of .025” or .001˝ (one thousandth of an inch). One complete revolution of the thimble therefore equals .025˝ or one line on the barrel scale. With that in mind, here’s a quick quiz: What is the reading shown in Figure 1?

How do you think you did? Did you come up with .385˝? If not, look at the drawing again. Each of the lines on the barrel represents .025 of an inch. Each of the longer lines (the ones with the numbers above them) equals .1˝ (4 x .025”). So, we’re showing 3 full lines (.300) and 3 of the small lines (.075). We’re up to .375˝. The last .010 is indicated by the reading on the thimble. Add that to the .375˝ and you have a reading of .385˝. Sounds a little confusing I know, but trust me, you’ll get the hang of it the more you do it. Heck, even my wife can read a micrometer now and I still can’t boil water.

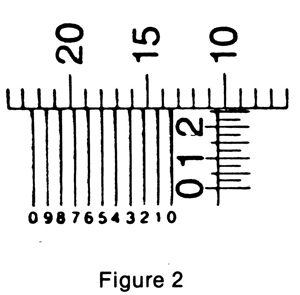

If you need more precise measurements, which is quite common in machining, you can achieve readings in ten-thousandths of an inch by using a Vernier scale (optional on some micrometers). The vernier scale, marked on the barrel, has ten divisions, each equaling 1/10 of 1/10,000”. The difference between a thimble division and a vernier division is 1/10,000 of an inch. Therefore, when the zero lines of the vernier exactly coincide with thimble lines (Figure 2), the number on the vernier lines is the difference between the vernier line and the next thimble line in ten-thousandths of an inch. Thus when the fifth line on the vernier coincides with a thimble line, the thimble has moved 5/10,000 of an inch.

Example:

First determine the number of thousandths, as with an ordinary micrometer. Then find a line on the vernier that exactly coincides with a thimble line. By adding the vernier reading to the thousandths reading the actual reading in ten-thousandths of an inch is obtained. The reading shown in Figure 2 is .260˝ plus .0005˝ or .2605˝.

Hopefully, you haven’t run screaming after all of that. It sounds confusing, but take your time and keep at it. It will make sense.

Jim Tapp is Tech Services Manager for Goodson Tools and an ASE-Certified Master Machinist.