Technicians often struggle to determine the coding when replacing a control module in a VW or Audi vehicle. Since there can be many choices based on the equipment installed in the car, how does one know which codes to use?

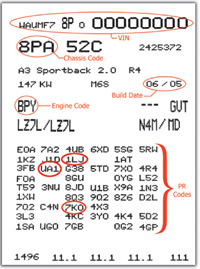

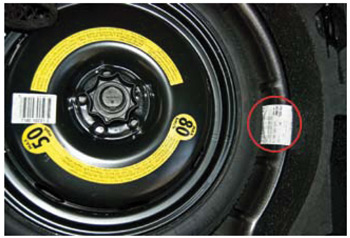

VW/Audi anticipated this problem. Each vehicle comes with two copies of the build sticker. The first is in the maintenance booklet. A sample is shown in Fig. 1. This sticker shows all of the installed equipment in the vehicle. If the maintenance booklet is not in the vehicle, a second copy of the sticker should be located near the spare tire well in the trunk as shown in Fig. 2 on an 8P chassis Audi A3.

Understanding the information on the sticker is key. All of the installed options are listed in the form of three-digit production codes called “PR codes,” as shown on the label below (taken from a 2006 Audi A3).

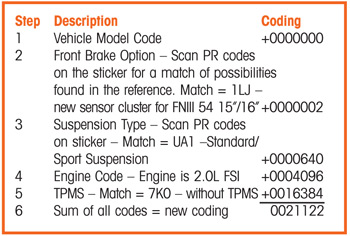

For an example on the use of these codes, assume that an ABS module failed on this A3. The old module is dead and won’t communicate with a scan tool so the original coding cannot be retrieved. Using the PR codes and a reference, such as a repair manual or the information found on the Ross-Tech Wiki, one can still figure out the coding needed.

For our example, we are using a specific Ross-Tech Wiki reference to Brake Electronics Coding.

We have to assemble the module coding by relating the PR code for the options that are present to the actual code value needed by the module. Once these are found, we then sum up all of the code values into one code number. (See Fig. 3)

Use your diagnostic tool to enter 0021122 as the coding for the replacement module.

Courtesy of Ross-Tech, LLC.