Affected Chrysler Intrepid Models:

1998-2002 2.7L, 1998-2001 3.2L, 1996-’97 3.3L and 1996-2002 3.5L

Symptom: Automatic overdrive transmission goes into second gear (limp-in mode) and will not shift, and trouble codes for the transmission solenoid pack are stored in memory.

Codes: P0750, P0755, P0760 and P0765

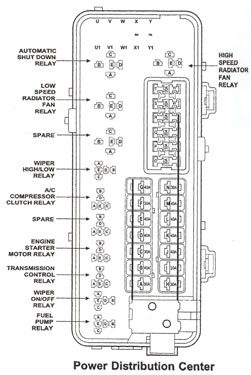

Problem 1 of 3: The transmission or electronic automatic transaxle (EATX) relay has a slower than normal response time causing the transmission control module (TCM) to set solenoid codes.

Test & Fix: Testing the response time of the transmission or EATX relay is usually unreliable. A quick test is to swap the relay with an identical relay on the vehicle or just replace it and retest.

Problem 2 of 3: The transmission solenoid pack has a solenoid winding that has higher or lower than normal resistance.

Test & Fix: Unplug the 8-way solenoid pack connector and check the resistance of each of the solenoid windings. Normal resistance is 1-3 ohms. Replace the solenoid pack if one or more solenoid windings have higher than normal resistance.

Problem 3 of 3: The TCM has one or more failed solenoid drivers.

Test & Fix: A labscope may be used to show that one or more solenoid drivers in the TCM is not fully grounding the solenoid while it is automatically performing the diagnostic test on it. The TCM is constantly monitoring the performance of the solenoids that are not currently being energized. Replace the TCM if one or more solenoid drivers are found to be defective.