Model(s): 2014-2019 Trucks with the 4.3L, 5.3L and 6.2L RPO Codes

– L82 – L83 – L84 – L86 – L87 – LT1 – LT4 – LT5

The latest generation of GM full-size trucks incorporate a new generation of technologies not previously seen in full size truck and utility applications. As a result these engines generate noises during cold start and during warm operation that owners of previous generation multiport fuel injection (MFI) vehicles may not be familiar with.

DIRECT INJECTION HIGH PRESSURE FUEL PUMP AND FUEL INJECTORS

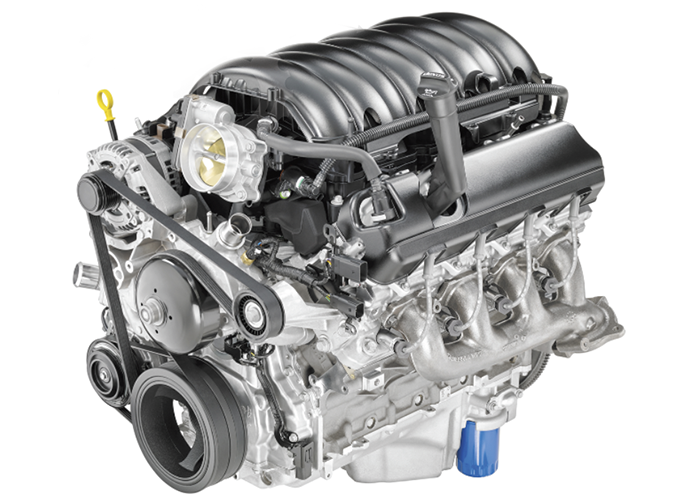

The new Small Block Generation 5 engine family incorporates a new fuel system technology known as direct injection (DI). With DI, fuel is injected directly into the cylinder using a high-pressure fuel system.

DI provides many benefits in improving engine efficiency. In particular, DI improves power, torque, and most importantly fuel efficiency. This technology is included as standard equipment on all Generation 5 engines in the small block engine family, which are the 4.3L V6, 5.3L V8 and the 6.2L V8.

The high-pressure fuel system does have unique operating characteristics; in particular, the noise emanating from the high-pressure fuel pump can result in a subtle ticking noise that is apparent when the vehicle is idling. The sound is more evident when outside around the vehicle, when the hood is open or the vehicle is operated in a drive-through. The sound may be more noticeable during a cold start, but lessens once the engine is warm. A slightly higher pitched clicking sound is the fuel injectors pulsing ON and OFF under the high fuel pressures. These sounds are a normal characteristics of the DI high pressure fuel system.

Another operating characteristic is a slightly longer crank time when the engine is started. The increased crank time is the result of the time required to build high pressure in the fuel system before the engine starts.

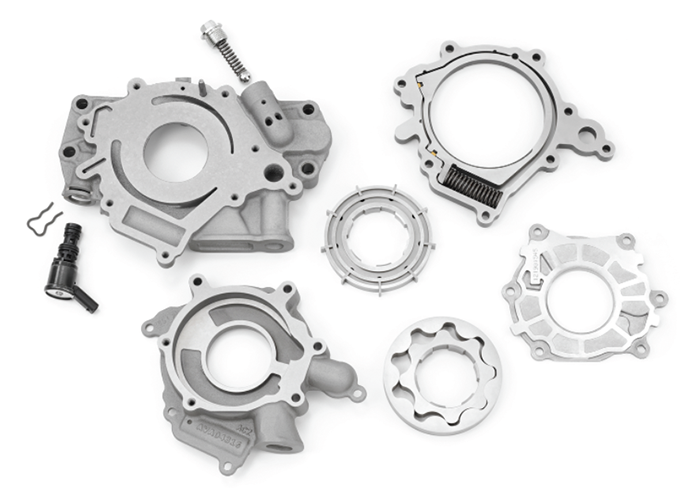

OIL PUMP COLD START RRRRP OR RASP

The oil pump design has changed from a gerotor gear type pump to a two-speed vane type pump for fuel economy reasons. At temperatures at or below 0°C (32°F), or when the engine has been sitting for a few hours, it is possible to have air enter the pump through normal oil drain back. Upon startup, the owner may hear a short “Rrrrp” or “Rasp” coming from the front of the engine. It is most often heard during a remote start. There is nothing wrong with the oil pump or oil system. No repairs should be attempted for this condition.

6.2L ENGINE – DRY SUMP OIL SYSTEM MOAN

The 6.2L engine dry sump oil system may generate a moan noise that may be heard inside the vehicle at idle and/or low engine rpm operation for approximately the first two minutes following a cold start. The noise cannot be heard from the outside of the vehicle.

This noise may be more noticeable on the passenger side of the vehicle and has been described as similar to the sound of running water. The dry sump oil system is hard mounted to the body of the vehicle, and at cold start, the oil moving through the system can transfer the noise to the body. This is a normal dry sump oil system operating characteristic and no repairs should be attempted.

Courtesy of General Motors