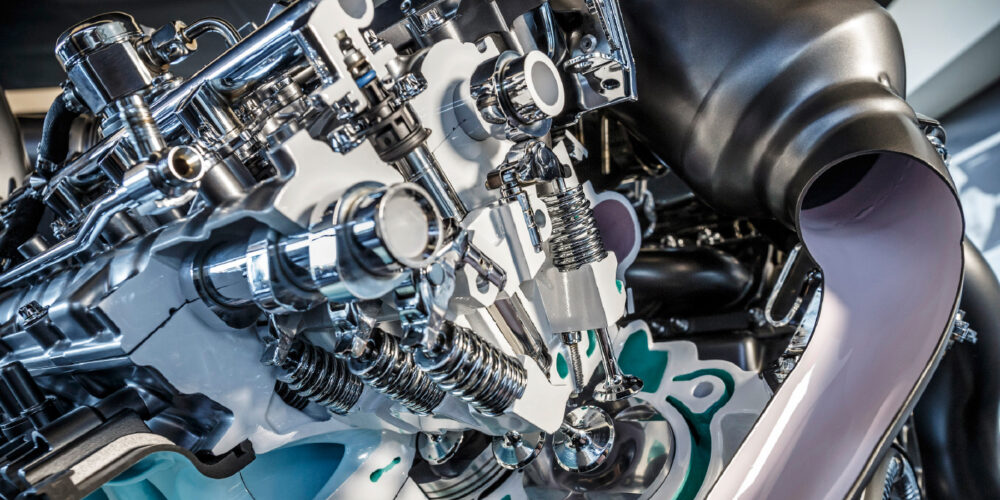

Damage signs on the turbocharger are usually the result of one of the following causes:

• If there is insufficient lubrication, the bearings will fail and the compressor and turbine wheels can grind against their housings.

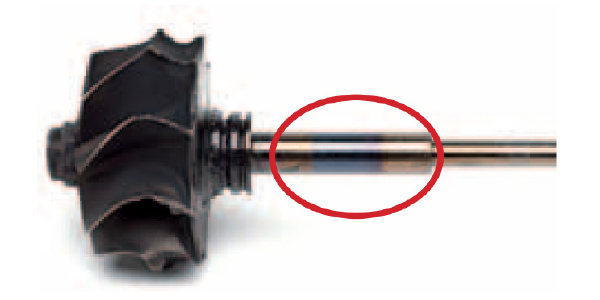

• Contaminated oil leads to score marks on shaft journals and bearings. Oil boreholes and seals can become clogged and cause insufficient oil supply.

• Foreign bodies that enter through a defective air filter can damage the turbine or compressor wheels. The resulting unbalance damages the turbocharger bearing.

Handling Replacement Turbochargers

A turbocharger is a complex unit with precisely matched components. When handling a turbocharger, remember:

• Do not modify the turbocharger. The design is optimized for a specific engine type. For this reason, no adjustments or modifications should be made. For example, if the boost pressure increases, it may cause the engine to overheat, resulting in damage to the pistons, cylinder head, or engine mounts.

• Use the correct engine oil. It’s critical to remember when changing the oil to only use engine oil recommended by the manufacturer. Any deviation in viscosity may cause incorrect lubrication and damage the turbocharger.

Courtesy of MAHLE