There are not too many vehicles with ignition systems that use ignition points. Most point ignition systems were abandoned by auto manufacturers beginning in the early 1970s as emission requirements started to change. The EPA changes called for a higher energy spark that would stay within specifications for more than 5,000 miles.

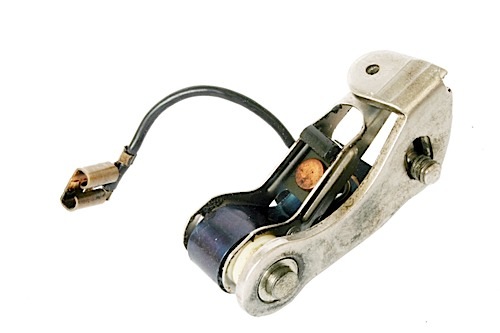

The primary problem with points is that they wear out. The contact points that conduct the battery voltage are typically made of tungsten, and can be slowly eroded by the spark. The contact pad that rides on the shaft of the distributor can wear and change the dwell. Also, the spring can lose tension over time and even break. Most point systems could not go past 4,000 RPM without the timing becoming unstable due to the arm bouncing on the distributor shaft.

The good thing about points was that they were adjustable. A technician with a set of feeler gauges (maybe a matchbook cover) and a dwell meter could tune the system. This is the reason they survived in marine applications until the 1980s.