The potential for inadvertently creating a misfire is very real when installing new spark plugs. I say this because I’ve diagnosed many misfires created by greasy fingerprints, broken insulators and incorrect air gaps — all caused by poor installation procedures. But nothing is as simple as installing a spark plug, right? After all, a spark plug has just three basic components: 1) the center electrode, 2) the porcelain insulator, and 3) the ground electrode, which is welded to the spark plug’s threaded metal shell. A resistor can also be built into the center electrode to help dampen radio frequency interference (RFI) caused by high-voltage electricity.

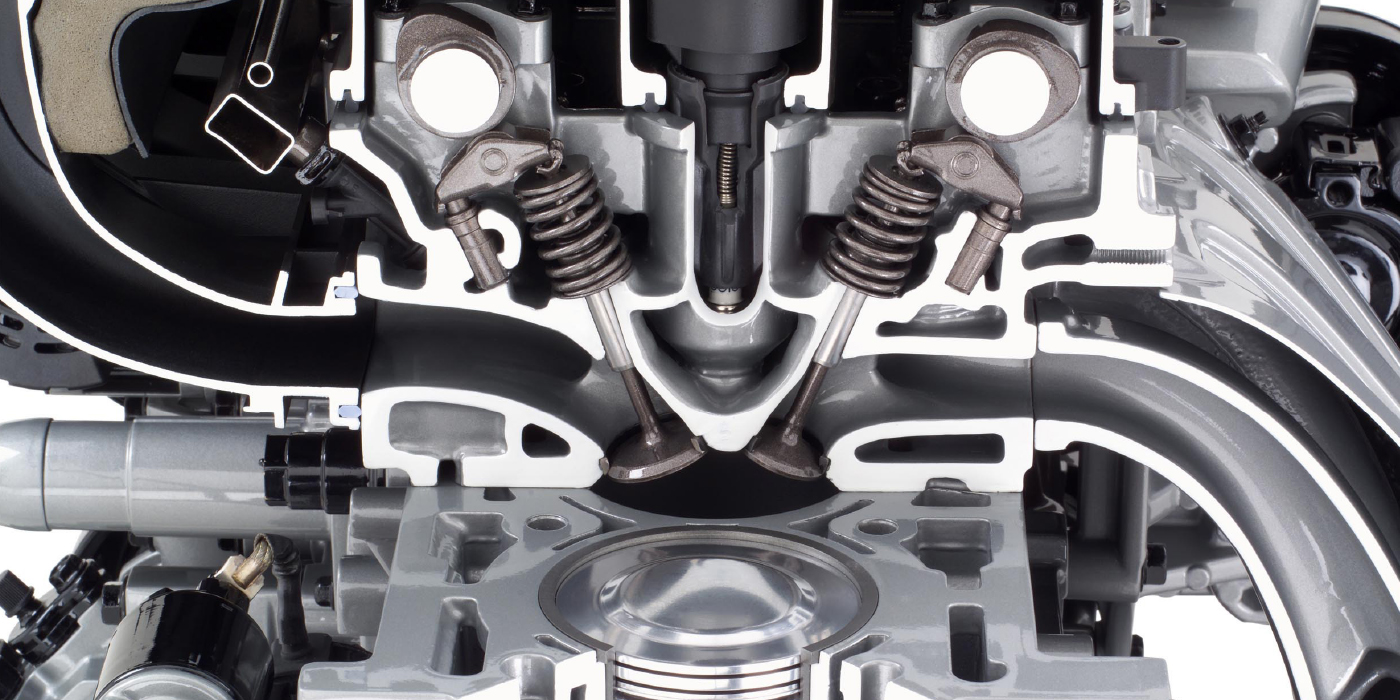

Simple in construction, yes, but spark plugs are very complex in function when delivering a timed spark in an engine that’s operating at speeds ranging from 600 rpm to 6,500+ rpm under many different loads and combustion chamber temperatures. To illustrate, a spark plug must withstand up to 60,000 volts jumping across an air gap of up to 0.080 inches at cylinder pressures exceeding 200 psi in naturally aspirated engines. Not to mention that, according to one manufacturer, spark plug insulator tip temperatures should operate above 932º F to prevent fouling and below 1,471º F to prevent pre-ignition.

MODERN ENGINES

The operating stresses on modern spark plugs are increased because modern engines are generally designed to operate at maximum running compression. Cranking compression, for example, might range between 180 to 200 psi at sea level. In contrast to cranking compression, a naturally aspirated engine with conventional port fuel injection and valve timing might produce about 80-90 psi running compression at idle speed. If the throttle is suddenly snapped open on a naturally aspirated engine, its running compression will usually exceed its cranking compression by as much as 10% to 20% because the engine’s volumetric efficiency often increases with engine speed.

If variable valve timing (VVT) is added, fuel economy can be increased by reducing intake and exhaust valve overlap, which increases running compression at low engine speeds. The engine’s torque output can be improved by increasing intake and exhaust valve overlap, which, in turn, increases running compression at higher engine speeds. Adding turbocharging or supercharging further increases running compression, which subsequently increases the load on the spark plugs.

Now, let’s add gasoline direct fuel injection (GDI), which allows the PCM to control the flow pattern of the fuel entering the cylinder. Since GDI systems inject relatively cold fuel directly into the combustion chamber, the combustion chamber is actually cooled, which allows engineers to increase compression ratios of GDI engines from a conventional 9.5:1 ratio to as high as a 14.0:1 ratio without detonating the air/fuel mixture.

Normally only racing engines burning very high octane gasoline or methanol could withstand such high compression ratios. But, when high compression is coupled with variable valve timing, engineers can adjust running compression to suit operating conditions by changing valve overlap. Here again, the spark plug is working harder than ever before to ignite very dense air/fuel mixture ratios.

THE MODERN SPARK PLUG

Due to rapid electrode wear, conventional mild-steel spark plugs used on older engines had to be replaced at intervals of 36,000 miles or less (see Photo 1). In contrast, spark plugs now last 100,000 miles or more because their electrodes are coated with precious metals that resist electrode wear. Many long-life spark plugs also feature very hard iridium-alloy center electrode designs that terminate into sharp needle-point configurations (see Photo 2). These configurations create a stable spark kernel at the high cylinder pressures used in GDI and turbocharged or supercharged engines.

Since heat range and electrode design are very important to preventing misfires, any long-life spark plug should be replaced with exactly the same heat range, shell and tip design. In addition, spark plug threads should be plated to prevent seizing in aluminum cylinder heads.

Now that we have the basics of spark plug design covered, let’s look at the do’s and don’ts of spark plug installation.

DO: REMOVE THE OLD SPARK PLUGS

One of the “do’s” in spark plug replacement is to loosen the spark plug about 1/8 turn to dislodge accumulated dirt from around the spark plug gasket or tapered seat. While wearing proper eye protection and taking precautions to prevent debris from entering the engine, use low-pressure compressed air to remove the loosened dirt and debris from the spark plug well.

If the spark plug is seized, the threads protruding into the combustion chamber are likely coated with hard carbon, which makes removal difficult. In passing, some technicians report that spark plugs are more easily removed if an intake decarbonization procedure or a commercial duty, in-tank fuel additive is used beforehand to remove carbon buildup in the combustion chamber.

The most common recommendation is to soak the spark plug with a high-quality penetrating oil and alternately loosen and tighten the spark plug until the carbon baked onto the end threads softens enough for complete removal.

On the upside, this is the safest procedure but, on the downside, this procedure can be extremely time-consuming in a production shop. If the spark plug can’t be removed, then extreme methods are justified, providing that the vehicle owner is made aware that the cylinder head might require a thread insert repair as a result.

DON’T: TORQUE SPARK PLUGS

Under-torquing a spark plug can be just as fatal as over-torquing a spark plug. Under-torquing is a “don’t” because a loose or improperly seated spark plug can overheat which can cause a pre-ignition or a misfire condition.

Over-torquing a spark plug is also a “don’t” because the insulator can be cracked. As a “do,” I recommend using a short, 200 in.-lb. capacity, click-release ratchet torque wrench to tighten spark plugs to specification. To convert a foot-pound specification into inch-pounds, simply multiply foot-pounds by 12. Most modern torque wrenches have a conversion scale imprinted on the handle for converting SAE into metric torque values. Torque values for 14 mm spark plugs range between 8 ft.-lbs. and 29 ft.-lbs., depending upon thread length and whether the cylinder head is made of aluminum or cast iron.

As a final note, most spark plug manufacturers discourage using anti-seize compounds on spark plug threads because metallic-based compounds can spatter onto the insulator tip and cause a misfire. The anti-frictional qualities of an anti-seize compound can also cause the spark plug to be over-tightened. Since some auto manufacturers do specify the limited use of an anti-seize compound, it’s best to check your

service information for correct lubricating procedures before installing the spark plugs into the cylinder head.