Applies To: 1998-2002 Accord L4 – all models with A/T and cruise control

Symptom: A thump as the ignition switch is released from the start position or as the engine starts. This noise sounds similar to a rubber mallet striking the frame and occurs only on a cold start (the vehicle has been sitting for some time, usually overnight).

Probable Cause: The vacuum-actuated engine mount does not work properly because of insufficient intake manifold vacuum at start-up.

Corrective Action: To increase vacuum, reroute the vacuum hose for the engine mount control solenoid valve to the cruise control vacuum tank.

Diagnosis: Ask your customer if the noise happens only on a cold

start, after the vehicle has been sitting for some time, usually overnight.

- If the noise happens only on a cold start, go to Repair Procedure A – 1998-2000 Accord below or Repair Procedure B – 2001-’02 Accord further down the page.

- If the noise happens at every start, disregard this bulletin, and look for other possible causes (exhaust hangers, rear engine mount, etc.).

Repair Procedure A: 1998-2000 Accord

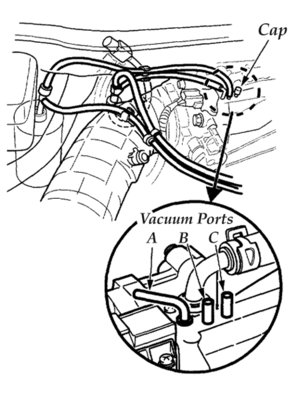

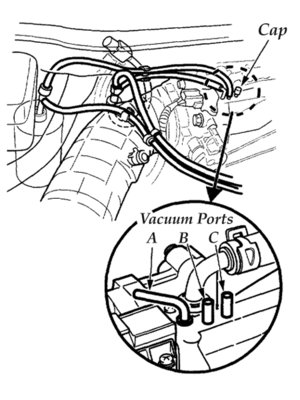

1. Look at the three vacuum ports on the top of the intake manifold. See Fig. 1. Is vacuum port C capped?

– If port C is not capped, replace the fuel pressure regulator and hose (see S/B 00-018, MIL Comes On With DTCs P0171 and/or P0172, filed under Fuel and Emissions). Then go to step 2.

– If port C is capped, go to step 2.

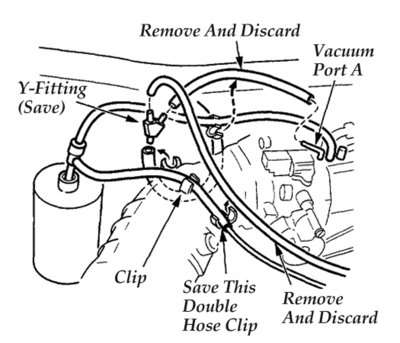

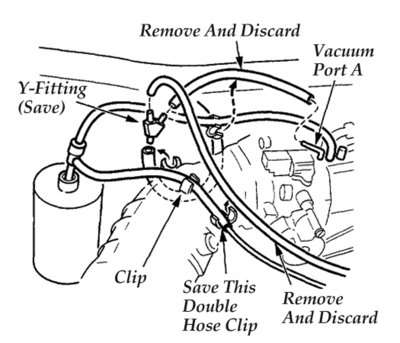

2. Disconnect the three vacuum hoses from the Y-fitting. See Fig. 2.

Save the Y-fitting.

3. Remove the hose from vacuum port A and discard it.

4. Remove and discard the long vacuum hose going to the fuel pressure regulator. Save the double hose clip.

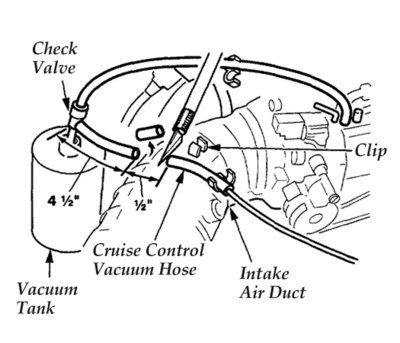

5. Unclip the cruise control vacuum hose from the intake air duct.

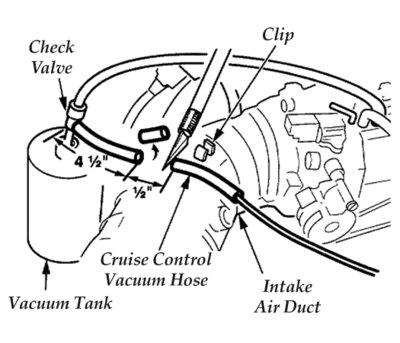

Measure 4-1/2 in. from the check valve on the cruise control vacuum tank, then remove a 1/2-in. section of the hose beyond this point with a utility knife. See Fig. 3.

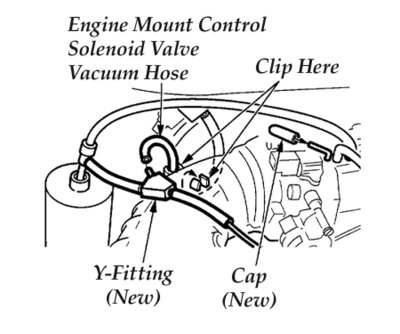

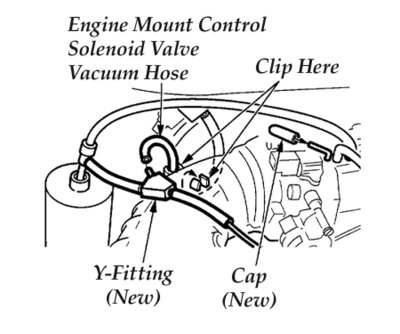

6. Connect the ends of the vacuum hose you just cut to the opposite ends of the Y-fitting you removed in step 2. See Fig. 4.

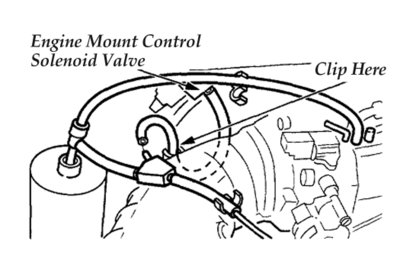

7. Connect the engine mount control solenoid valve vacuum hose to the

open port on the Y-fitting. Push the hose into the clip on the side of the intake air duct.

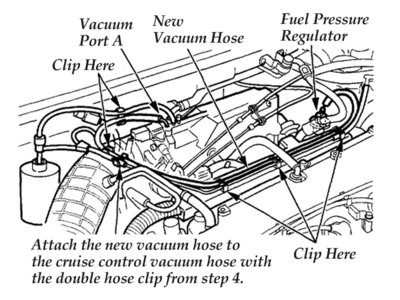

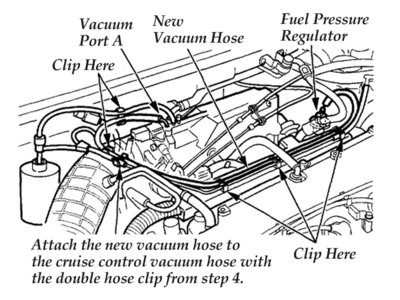

8. Cut a 34-in. length of 3.5 mm ID vacuum hose, then connect one end to vacuum port A and the other end to the fuel pressure regulator. Push the new hose into the clips at the locations shown in Fig. 5.

Repair Procedure B: 2001-’02 Accord

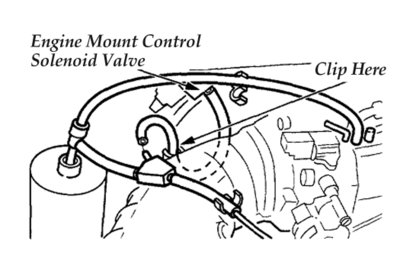

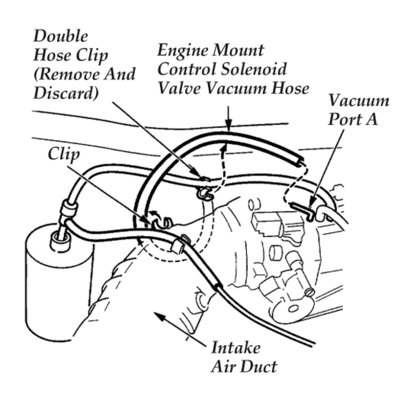

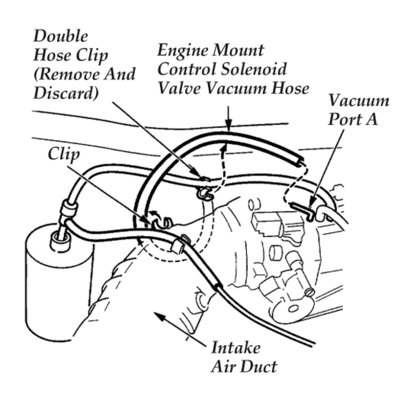

1. Disconnect the engine mount control solenoid valve vacuum hose from vacuum port A. See Fig. 6. Unclip the hose from the double hose clip and from the side of the intake air duct. Remove and discard the double hose clip.

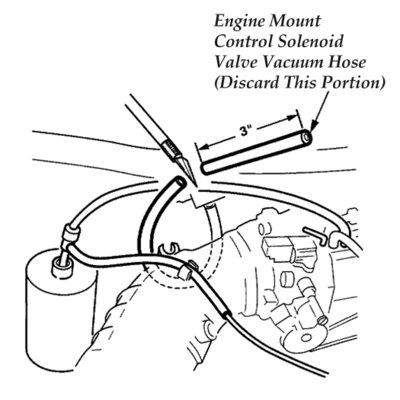

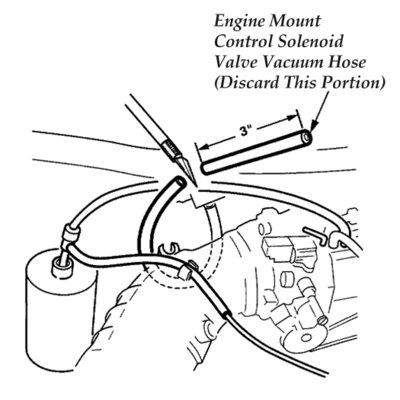

2. Measure 3 in. from the open end of the hose, and remove that section of hose with a utility knife. See Fig. 7.

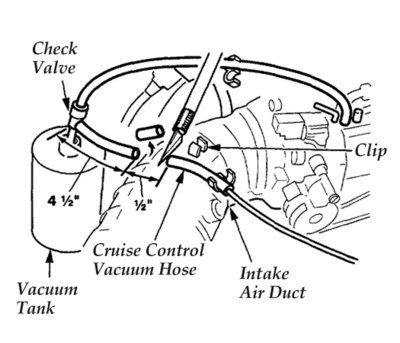

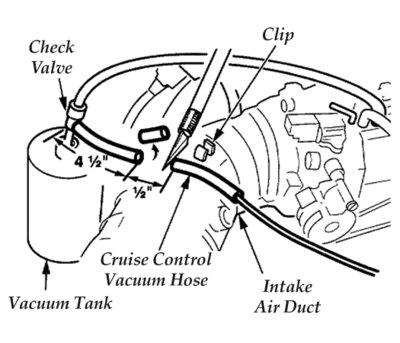

3. Unclip the cruise control vacuum hose from the top of the intake air duct. Measure 4-1/2 in. from the check valve on the cruise control vacuum tank, then remove a 1/2-in. section of the hose beyond this point with a utility knife. See Fig. 8.

4. Connect the ends of the vacuum hose you just cut to the opposite ends of the new Y-fitting. See Fig. 9.

5. Connect the engine mount control solenoid valve vacuum hose to the open port on the Y-fitting. Push the hose into the clip on the side of the intake air duct.

6. Push the cruise control vacuum hose into the clip on the top of the intake air duct.

7. Push the new cap onto vacuum port A.