Professional automotive technicians and do-it-yourselfers now have access to 84 additional sensors, switches and emissions, ignition and fuel injection parts covering approximately 34.6 million late-model vehicles through the latest expansion of the Wells Vehicle Electronics product line. Wells components, which feature original equipment or problem-solving “better than OE” designs, are available from leading automotive parts distributors throughout the U.S. and Canada.

Professional automotive technicians and do-it-yourselfers now have access to 84 additional sensors, switches and emissions, ignition and fuel injection parts covering approximately 34.6 million late-model vehicles through the latest expansion of the Wells Vehicle Electronics product line. Wells components, which feature original equipment or problem-solving “better than OE” designs, are available from leading automotive parts distributors throughout the U.S. and Canada.

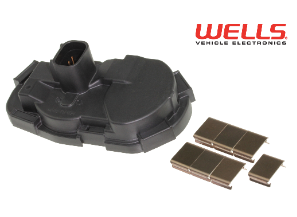

Among the new parts now available through Wells distributors is an economical throttle position sensor (TPS4270) that for the first time is available separate from the complete throttle body for an estimated 4.1 million 2005-2013 General Motors vehicles. Wells also has introduced five additional sensors, 54 new replacement switches, nine emissions parts, eight fuel injection components, and seven additional ignition parts for late-model foreign nameplate and domestic applications.

“Our product management and engineering teams remain in close contact with customers and monitor vehicle application data to help ensure that we offer the most up-to-date and efficient range of parts in each product category,” said Bill Nonnamaker, vice president of sales and marketing, Wells Vehicle Electronics. “The result is a higher level of service for the end user, which ultimately leads to increased sales and loyalty for our channel partners.”

To learn more about the Wells Vehicle Electronics product line, contact your nearest Wells distributor or visit www.WellsVE.com. The Wells website also includes a comprehensive, free electronic catalog as well as an extensive library of vehicle diagnostic resources.