Oil seepage may occur from the left side of the cylinder head at the lower mounting bolt for the intake manifold support bracket due to a casting shrinkage issue.

Oil seepage may occur from the left side of the cylinder head at the lower mounting bolt for the intake manifold support bracket due to a casting shrinkage issue.

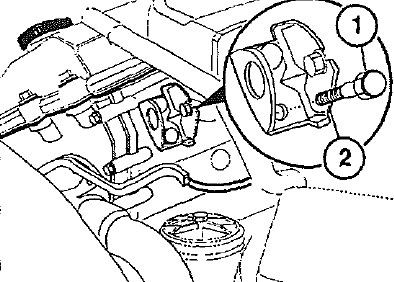

The leak is located around the lower mounting bolt (1) for the intake manifold support bracket is between the M6 threaded hole for the timing chain tensioning rail mounting and the M8 threaded hole for the intake manifold support bracket (see illustration). On M42 engines produced since approximately April of ’93, the lower mounting bolt for the intake manifold support bracket has been installed with 3 Bond 1209 and is marked with a black paint spot. If oil seepage is evident coming from the lower mounting bolt (1) for the intake manifold support bracket, remove the bolt and decrease the threads (2) along with the bolt hole threads. Apply liquid sealing compound 3 Bond 1209 (BMW P/N 07 58 9 062 376) on the bolt thread and reinstall bolt.

Some or all of this information was provided by the Automotive Parts Remanufacturers Association (APRA). For more information on technical bulletins available through APRA call 703-968-2772 or visit www.AutoBulletins.com.