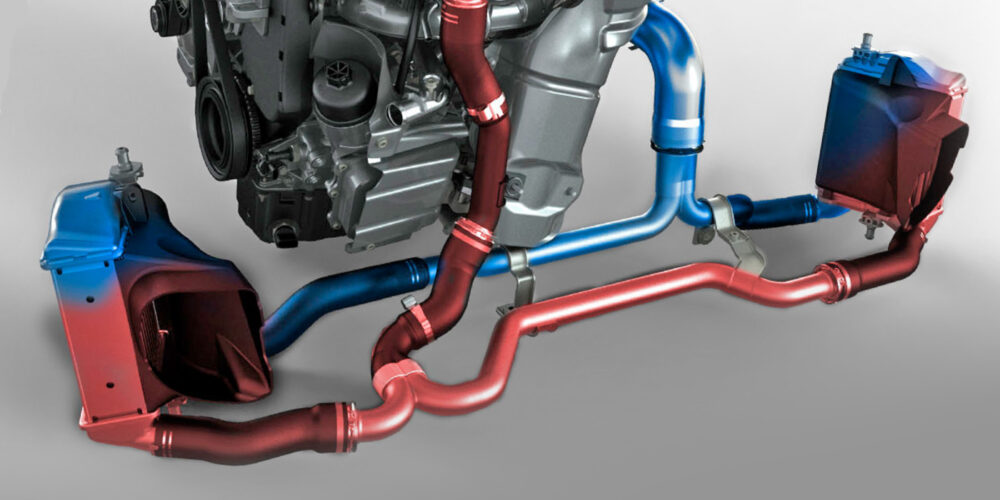

In a four-stroke internal combustion engine, camshafts rotate at half the speed of the crankshaft. Camshafts are usually linked to the crankshaft via a timing belt or a timing chain. Alternative solutions may include using a gear drive for the camshafts, as seen in VW V10 TDI engines. The proper synchronization of camshaft and crankshaft motion is crucial for controlling the movement of the valves and pistons inside the engine. The intake and exhaust valves have to open at a very precise time in relation to the piston position (cranking angle). Without the proper timing of these parts, the engine will suffer a catastrophic failure. This is exactly what happens when a timing chain or timing belt breaks.

For old-school engines using a timing belt, the easiest way of preventing such failures is to replace the belt at regular intervals as a part of the scheduled service maintenance. Most vehicle manufacturers recommend that timing belts be changed every 60,000 to 100,000 miles, or after 8 to 12 years. However, many modern engines use timing chains, which reside inside the engine and are not generally considered serviceable parts.

Both timing belts and timing chains use tensioners that keep them from moving around. However, timing chain tensioners, in contrast to timing belts, are nearly always controlled with the engine oil pressure. It is very important that the oil’s properties remain constant — or “stay in grade” — during the service life. If the engine oil pressure becomes low, the mechanical engine timing will be affected, which is not good for the engine.

One might expect that low oil pressure indicates a problem with the oil pump, but that is not necessarily the case. Very often, using an out-of-spec motor oil, such as one with a lower viscosity than what is recommended by the vehicle manufacturer, will cause low oil pressure.

Wear is another serious problem plaguing timing chains, especially in T-GDI engines. The issue has gained a lot of publicity as it relates to frequent failures of 1.2L and 1.4L VW TSI engines. Without conducting proper research and testing, some lubricant companies were quick to launch aftermarket additive packages that contained zinc dithiophosphate (ZDDP), which only further elevated the problem. Research carried out by BIZOL reveals that excessive ZDDP levels might actually accelerate the timing chain wear. The issue has become so severe that OEMs were forced to initiate joint task-force development of a dedicated timing chain wear (TCW) test that is to be included in the forthcoming ILSAC GF-6 performance specifications for passenger car motor oils.

Courtesy of Prof. Dr. Boris Zhmud, Head of R&D, BIZOL Lubricants, www.bizol.us.