Avoiding the Wallet Flush By Gary Goms Contributing Editor

Many shops are recovering revenues lost to a shrinking repair market by “upselling” fluid maintenance services or, as they’re commonly called in the aftermarket, “fluid flushes.” In other words, adding a fluid flush to a money-losing routine oil change can boost a shop’s average repair order amount into the range needed for true profitability.

Automotive equipment manufacturers have been quick to respond by manufacturing a variety of fluid-flushing machines designed to remove dirty, oxidized fluids from engines, cooling systems, automatic transmissions, power steering pumps, braking systems and drive axle assemblies. In most cases, these machines will shorten fluid replacement times by automatically installing an equivalent volume of factory-fresh fluid. In all cases, fluid flushing is a relatively low-skilled, but highly profitable service for any undercar shop operation.

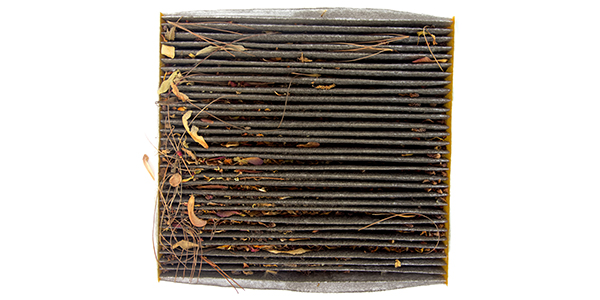

OVERSELLING: “WALLET FLUSHING”

While fluid flushing sounds like an excellent method for boosting shop income, and better-maintaining your customers’ vehicles, many quick-lube and maintenance-based shops have been accused of overselling fluid maintenance services. Overselling fluid maintenance has become known in the industry as “wallet flushing,” and has created a great deal of controversy over how often these services should be performed. At even the most ethical level, the controversy rages between shops that have developed guidelines based on their own repair histories and others that faithfully follow the auto manufacturer’s recommended maintenance schedules. With those thoughts in mind, let me share some common views regarding fluid maintenance.

ENGINE FLUSHING

When discussing engine flushing, it’s important to remember that, if the correct OE-specification oil has been installed, most OE oil change intervals will prevent sludge deposits from forming in the engine during normal driving cycles.

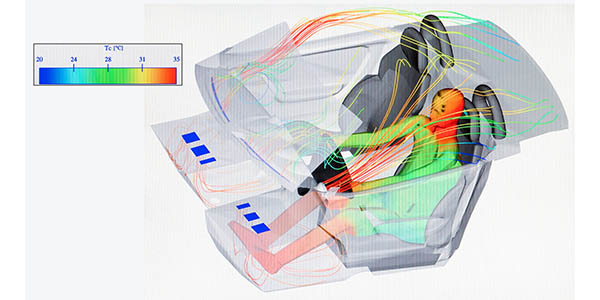

Traditionally, vehicle manufacturers have adhered to mileage-based service oil change intervals, with “average” and “severe” use being the only modifiers to the mileage-based formula. Currently, the trend is moving from mileage-based to computer-based strategies to estimate oil life. When the oil contamination exceeds a predetermined value, an “oil life monitor” may command the vehicle’s Powertrain Control Module (PCM) to activate a “maintenance required” light on the instrument panel. In other applications, the PCM records data parameters like average ambient and engine coolant temperatures, engine loads and trip lengths, and uses that data to calculate an oil change interval. When that calculated data indicates oil life is minimal, the maintenance required light is illuminated.

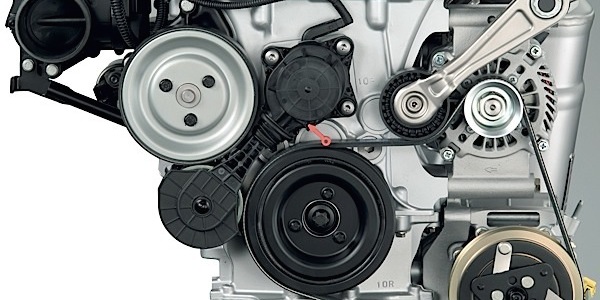

Unfortunately, some manufacturers have under-estimated the effects that certain driving conditions can have on specific engine designs. Short-trip, cold-weather operating conditions cause sludge to build rapidly on an engine’s internal surfaces. In some instances, engine design factors may reduce the capability of the crankcase ventilation system to remove combustion blow-by gases. In others engines, the average oil temperature might be lower or higher than normal, which contributes to sludging and gelling. Engine flushing, quite obviously, is designed to remove internal sludge deposits formed by abnormal operating conditions. The core issue is that the flushing process may only loosen, rather than completely remove, sludge deposits in heavily sludged engines. In this case, merely loosening engine sludge may allow the sludge to clog the oil pump inlet screen and starve the engine for oil.

In a more optimistic scenario, flushing might prove valuable if the vehicle owner has skipped several oil change intervals and the engine needs the old, viscous oil removed. On the other hand, it’s anybody’s guess if the sludging condition has passed the point of remediation on high-mileage engines with many skipped oil changes.

For this reason and for the reason that flushing solvents might contaminate the new engine oil, some auto manufacturers have indicated that engine flushing is not a recommended service for their line of vehicles. Whatever the case, it’s important to study the manufacturers’ technical service bulletins regarding the topic before recommending an engine flush.

COOLANT FLUSHING

Coolant exposed to several different metals, such as cast iron, brass and aluminum, will develop a condition called “electrolysis,” in which the coolant becomes an electrolyte that causes the metals to act like positive and negative plates in a battery. In worst-case scenarios, electrolysis erodes gaskets and the gasket interface between finely machined cylinder head and intake manifold surfaces until the gasket can no longer contain the coolant.

Although most manufacturers have reduced electrolysis and other cooling system issues through the use of better materials and coolant additive packages, the coolant still needs replacement at regular intervals. Conventional coolants should be flushed or exchanged each two years. Long-life coolants should be flushed at the manufacturers’ recommended intervals or as experience dictates with a particular nameplate. Can coolant flushing be oversold? Of course, just as with any other service. On the other hand, when the cost of a coolant flush is balanced against the expense of replacing an expensive radiator and heater core, the service can easily be justified to the vehicle owner.

AUTOMATIC TRANSMISSION FLUSHING

The automatic transmission service industry began the practice of fluid flushing because flushing is the only method in which contaminated and oxidized fluid can be removed from the transmission torque converter, oil cooler and clutch assemblies. Although synthetic transmission fluids are now being used to reduce oxidation and component wear, the life of any fluid can be drastically reduced by activity that exposes the fluid to excessive humidity or prolonged high-operating temperatures.

Because an automatic transmission’s control valve body is a close-tolerance mechanical device that’s extremely sensitive to fluid viscosity, clutch debris and varnish from oxidized fluid, replacing the fluid and filter at regular intervals has traditionally been a highly recommended service.

One of the hurdles to overcome in flushing automatic transmissions is dealing with the diversity of fluids being used in modern cars. Because many nameplates require special transmission fluids, substituting special fluids with “generic” grades or diluting the new fluid with other grades leaves open a liability issue if the transmission fails at a later date. If the fluid is also being changed in electronically controlled transfer cases, the same rules apply regarding the substitution of fluids.

Changing the transmission filter before a flush is another issue that should be dealt with. Some technicians feel that modern transmissions don’t need frequent filter changes, but do need the fluid replaced on a regular basis. In most instances, modern automatic transmissions don’t clog their oil filters with large quantities of clutch debris.

On the other hand, a technician doesn’t know if the filter might be clogged unless he removes the oil pan. Because some customers often demand a fluid flush in a desperate attempt to save an ailing transmission, removing the oil pan for inspection seems like good insurance against a future liability.

POWER STEERING & BRAKING SYSTEMS

Most power steering systems accumulate fluid-born debris from internal pressure hose deterioration, moisture absorption and seal wear. DOT 3 brake fluids attract atmospheric moisture and, like a power steering system, braking systems also generate fluid-born debris generated by corrosion and wear of internal sealing and hydraulic components.

Brake flushing is required by many manufacturers every two years to remove corrosive moisture from the system. Although I don’t know of similar requirements on power steering systems, installing fresh fluid should go a long way in reducing hose and seal failures.

Whatever the circumstance, most power steering and brake flushes are low-cost maintenance work that more than pays their way through increased component reliability.

DRIVE AXLE ASSEMBLIES

Manufacturers have traditionally incorporated drain plugs in their axle housings to expedite changing the axle oil at specified intervals. Extreme service, off-road fording of creeks or driving in deep flood water will often turn the clear axle oil into a rusty, muddy or milky-looking fluid. In this instance, the axle oil should be changed before expensive bearing races become pitted and corroded. Left unattended, moisture will ruin any drive axle assembly.

WHEN TO FLUSH

According to some import manufacturers, using discoloration to condemn a fluid is, at best, a subjective method of evaluation. The exception to that statement, obviously, would be if the fluid is severely contaminated with water or particulate matter.

A more objective method is to use fluid test strip kits to evaluate fluid condition. If a shop is performing fleet maintenance, using a reputable testing laboratory to analyze fluid samples is a very cost-effective and objective method for estimating fluid life.

In any case, fluid maintenance or “fluid flushing” is becoming an increasingly important method of extending the service lives of all vehicles.