Air conditioning odors typically result from the uncontrolled growth of bacteria and other microorganisms in the evaporator. Research by independent laboratories has found fungi such as Aspergillus, Cladosporium, Penicillium and others growing on cooling coils and other A/C system areas.

How do these microorganisms get there? They are naturally present in outdoor air and are drawn into the evaporator during air conditioner operation. Moisture also contributes to A/C odor formation. Most of the moisture that condenses on cold surfaces inside the system drains harmlessly over time. However, some moisture continues to cling to coil surfaces after the A/C shuts down. Microbial contaminants in the air combine with this lingering moisture in the evaporator. The warm, dark and moist conditions in the evaporator provide an ideal breeding ground for bacteria, mold and mildew to grow and generate musty odors.

To get rid of the unwanted organisms, various chemicals can be sprayed on the evaporator directly or through the blower ducts or air intake. Some of these chemicals are designed to be applied by DIYers. However, independent repair shops and dealerships that provide A/C service can offer some of these de-smelling solutions.

DISCOVERING AN A/C EVAPORATOR ODOR

A musty odor may be emitted from the air conditioning system of some vehicles that are usually operated in areas with high temperatures and humidity. It’s most noticeable when the air conditioner is first turned on after the vehicle has been parked for several hours.

The odor could result from one or more of the following conditions:

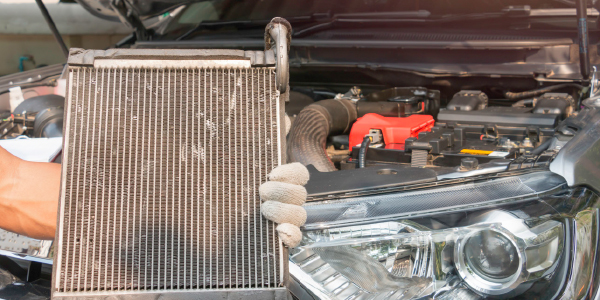

- Blockage of the evaporator housing drainpipe, resulting in a buildup of condensation. Check the evaporator housing drainpipe for blockage. If no problems are found, the evaporator and housing should be cleaned and disinfected.

- Microbial growth in the evaporator, arising from dampness in the evaporator housing where the cooling airflow is dehumidified. Condensation can make this growth explode.

- Breakdown of the coatings on the evaporator designed to kill bacteria. Most evaporators have a silver-based epoxy coating that prevents growth of bacteria in the fins of the core.

- The HVAC system software. Yes, software can cause odors. Some automakers have issued reflash updates for the module controlling the blower motor. Some updates increase the amount of time the blower runs after the key is turned off.

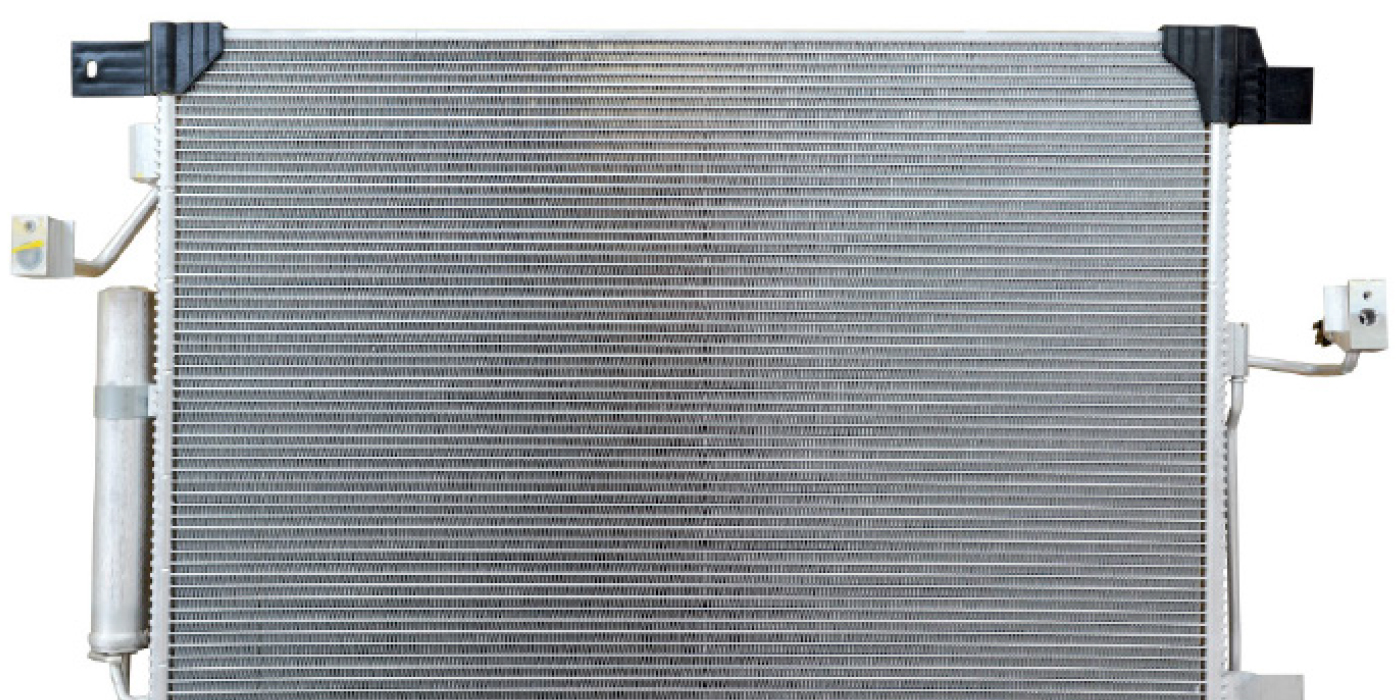

DOWNSIZED EVAPORATORS TRAP MORE MOISTURE

As carmakers downsized vehicles while also increasing their glass content in recent years, A/C system manufacturers reduced evaporator size while simultaneously increasing fin count. Thus, these densely packed evaporators trap and hold more moisture.

To see this for yourself, dip your hand into a glass of water. As you remove your hand from the water, quickly spread your fingers apart. No water will bridge the gap between your fingers. Dip and remove your fingers again, this time spreading them slowly to only a fraction of an inch apart. Water will bridge the smaller gap between your fingers and remain far longer than if you open your fingers wide.

WAYS TO REDUCE ODOR

Some odor treatments are merely feeble attempts to cover up odor. Here is a brief description of the performance capabilities of various odor treatments by product type:

- Disinfectants: Destroy odor-causing microorganisms on contact. The typical liquid disinfectant quickly evaporates or washes out of the system along with the condensation that forms during A/C use. The next time airborne bacteria enters the system, odor can occur again. For this reason, disinfectants can require repeat applications to control odor. Some disinfectants can damage the coatings on the evaporator core and even degrade the seals in the HVAC system. Use only disinfectants that are safe for the system.

- Smoke/Mist Application: Smoke and mist products combine a liquid disinfectant with a fine spray application technology. The spray is directed toward air intake vents inside the passenger compartment, so it reaches down into the air conditioning evaporator where odor-causing microorganisms colonize and grow. Ease of application is a plus, but again, the disinfectant quickly drains from the system, leaving no long-term protection against odor recurrence.

- Cabin Air Filters: Catch and absorb particulates and some gases as they pass through ducts to the passenger compartment. Many filters use activated charcoal. Filters become saturated or their active ingredient loses effectiveness over time and must be replaced. Some filters cannot catch gaseous odor molecules, which can be small. Filters do not eliminate the source of odor-causing microorganisms.

- Chemical Reactants: Reduce odor by combining with molecules of the odor-causing microorganism. The new, combined molecules must then be removed (wiped up with a dry towel, washed away in a liquid, etc.) to complete the odor treatment. Like liquid disinfectants, chemical reactants provide only a short-term treatment, and can allow odors to return quickly.

- Antimicrobial Agents: Have a wide range of successful microbial-control applications, from inhibiting fungal growth on boat hulls to preventing mold and mildew growth in carpet and wall coverings. One unique antimicrobial product used on mobile air conditioner odors combines its active ingredient with an acrylic resin that is sprayed into the evaporator. The acrylic resin dries onto the evaporator coils, forming a coating that sheds moisture better than uncoated coil surfaces. The antimicrobial agent remains embedded in the coating, where it kills or inhibits the growth of any microorganisms that attempt to settle on the surface. Together, the antimicrobial and acrylic resin coating last in the A/C system for up to three years, protecting against moisture and the growth of odor-causing microorganisms.